Film-type water-cooling lining wear-resistant plastic slag-roughing device

A technology that can be plasticized and lined. It is applied in the direction of burning fuel in a molten state, lighting and heating equipment, and fluidized bed combustion equipment. It can solve problems such as ash leakage, poor safety, and short service life, and avoid potential safety hazards. The effect of high pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

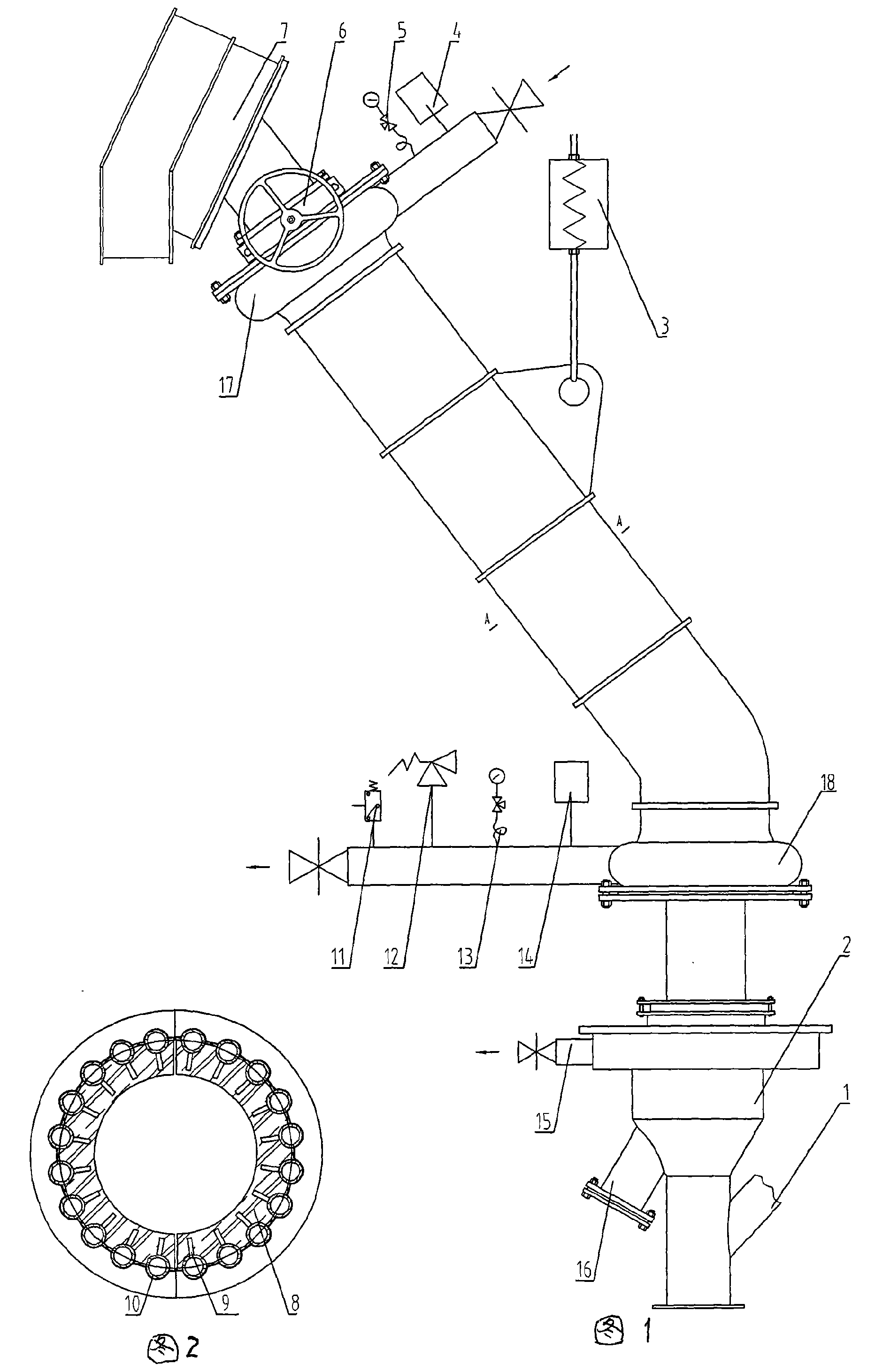

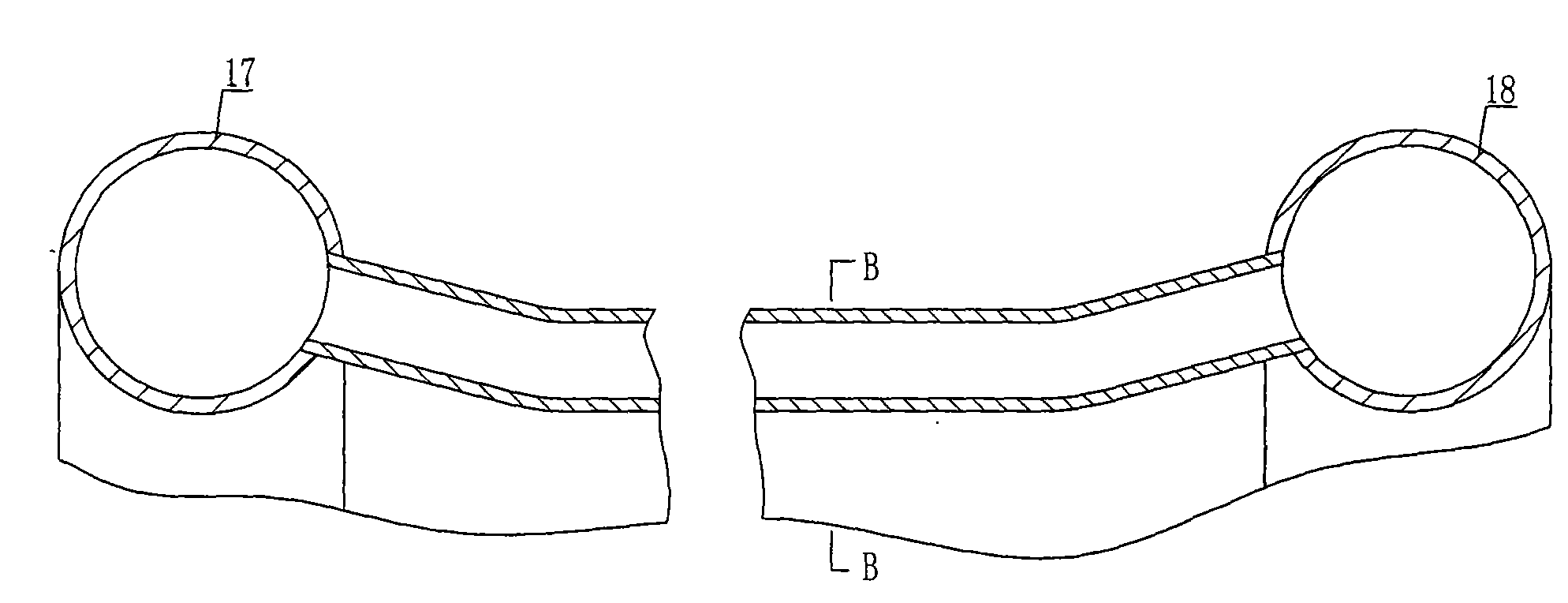

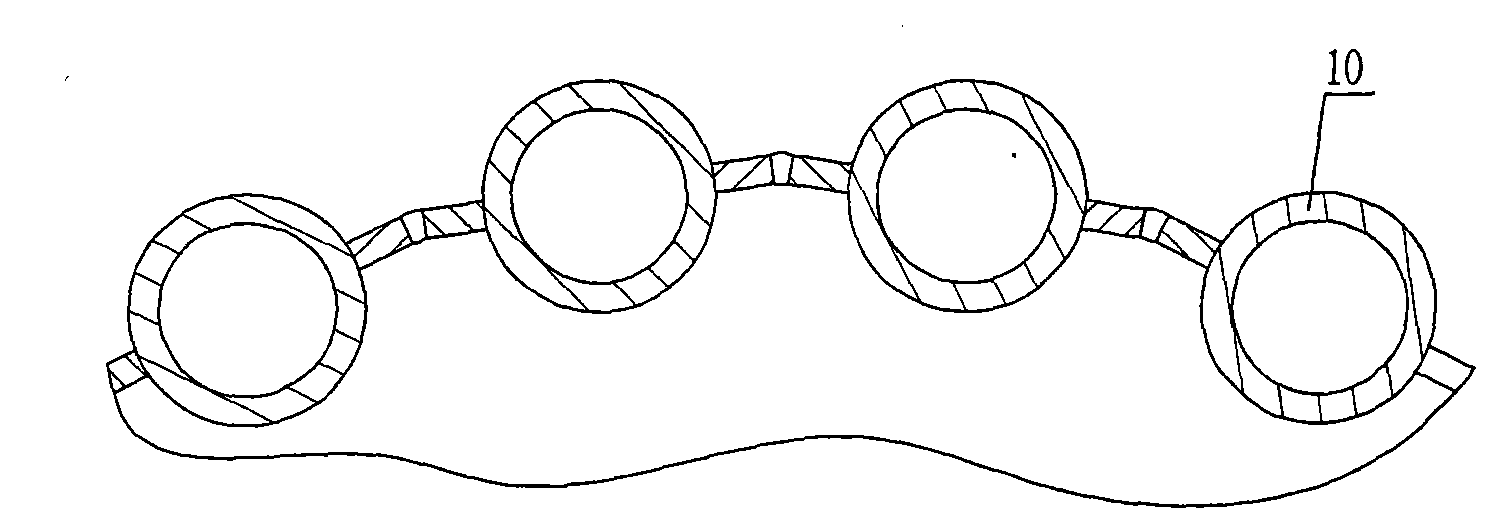

[0018] In the accompanying drawings, 1. External bed ash outlet; 2. Three-dimensional expansion joint; 3. Spring hanger; 4. Inlet water thermometer; 5. Inlet water pressure gauge; 6. High temperature ash; 7. CFB slag discharge interface ; 8. Wear-resistant plastic (that is, wear-resistant castable); 9. (Anti-shedding) pin; 10. Fin tube; 11. Pressure switch; 12. Safety valve; 13. Outlet water pressure gauge; 14. Outlet water thermometer; 15. Air induction sealing device; 16. Accident slag discharge pipe; 17. Cooling water distribution ring pipe; 18. Cooling water collection ring pipe.

[0019] figure 1 figure 2 It is shown that the new model includes a slag discharge interface and a slag lowering pipe. A plurality of finned tubes 10 are evenly distributed along the inner wall of the slag lowering pipe. Adjacent finned tubes are welded to form an annular tube panel used as a slag lowering channel. A plurality of finned tubes communicate with the cooling water distribution rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com