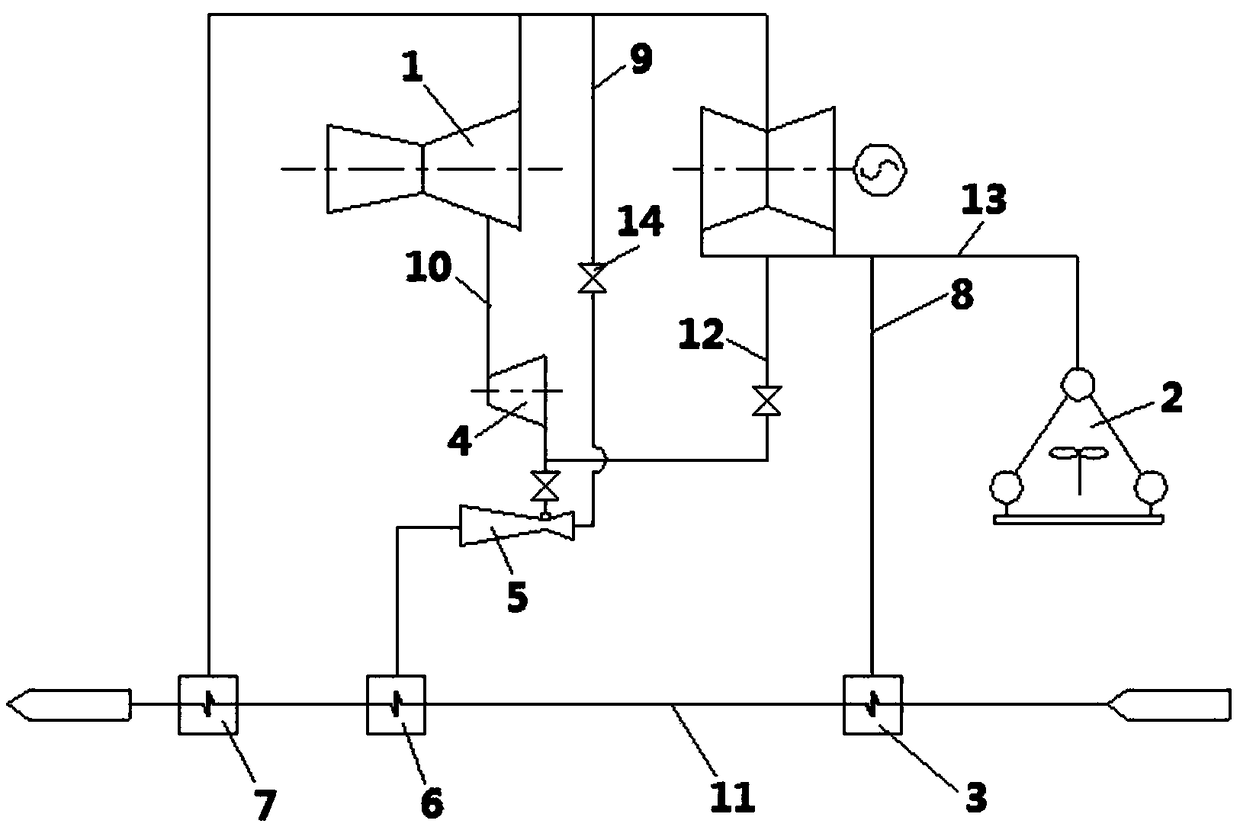

Feed water pump turbine steam exhaust waste heat recovering and recycling system

A feed pump steam turbine, waste heat recovery technology, applied in steam applications, steam engine installations, mechanical equipment and other directions, to achieve the effects of good compatibility, easy implementation and perfect adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] A power plant is installed with two 300MW direct air-cooled units, the feed pump is driven by a condensing small steam turbine, and the small steam turbine and the large steam turbine share an air-cooled island to cool the exhaust steam. The large steam turbine has been converted into a high back pressure operation unit for heating in winter.

[0042] The power plant was originally designed to run at a back pressure of 15KPa.a in winter, that is, the designed back pressure of both the large steam turbine and the small steam turbine in winter is 15KPa.a. After changing to high back pressure operation unit, the operation back pressure of large steam turbine in winter is raised to 35KPa.a.

[0043] When running with high back pressure in winter, it also causes the back pressure of the small steam turbine to increase (from 15KPa.a to 35KPa.a). An increase in back pressure will result in insufficient output of the small steam turbine.

[0044] Therefore, changing to high b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com