Combustion chamber for engine

A combustion chamber and engine technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve the problems of failing to meet low pollution requirements, high combustion zone temperature, low flame temperature, etc., to reduce temperature and reduce NOx emissions , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

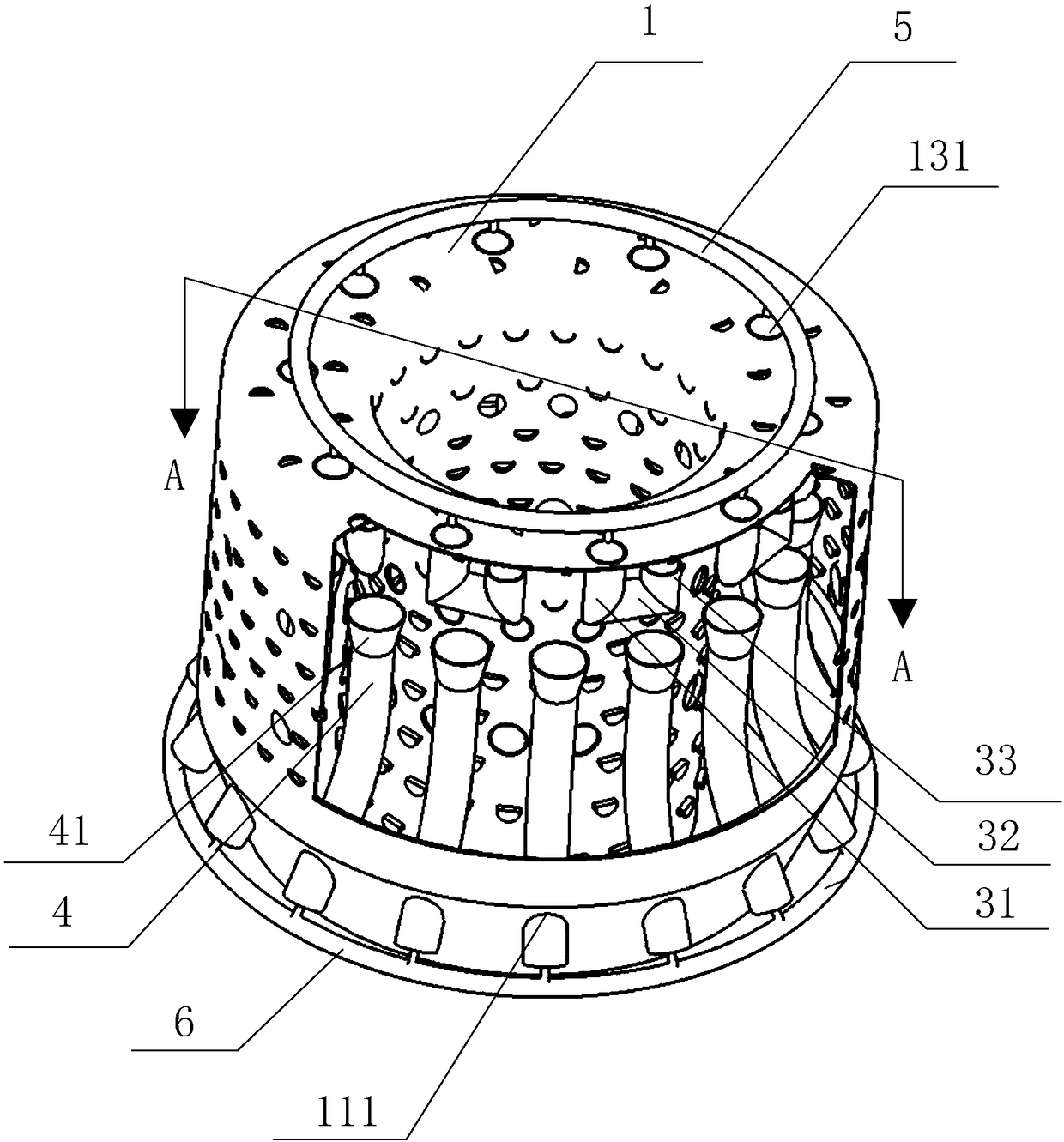

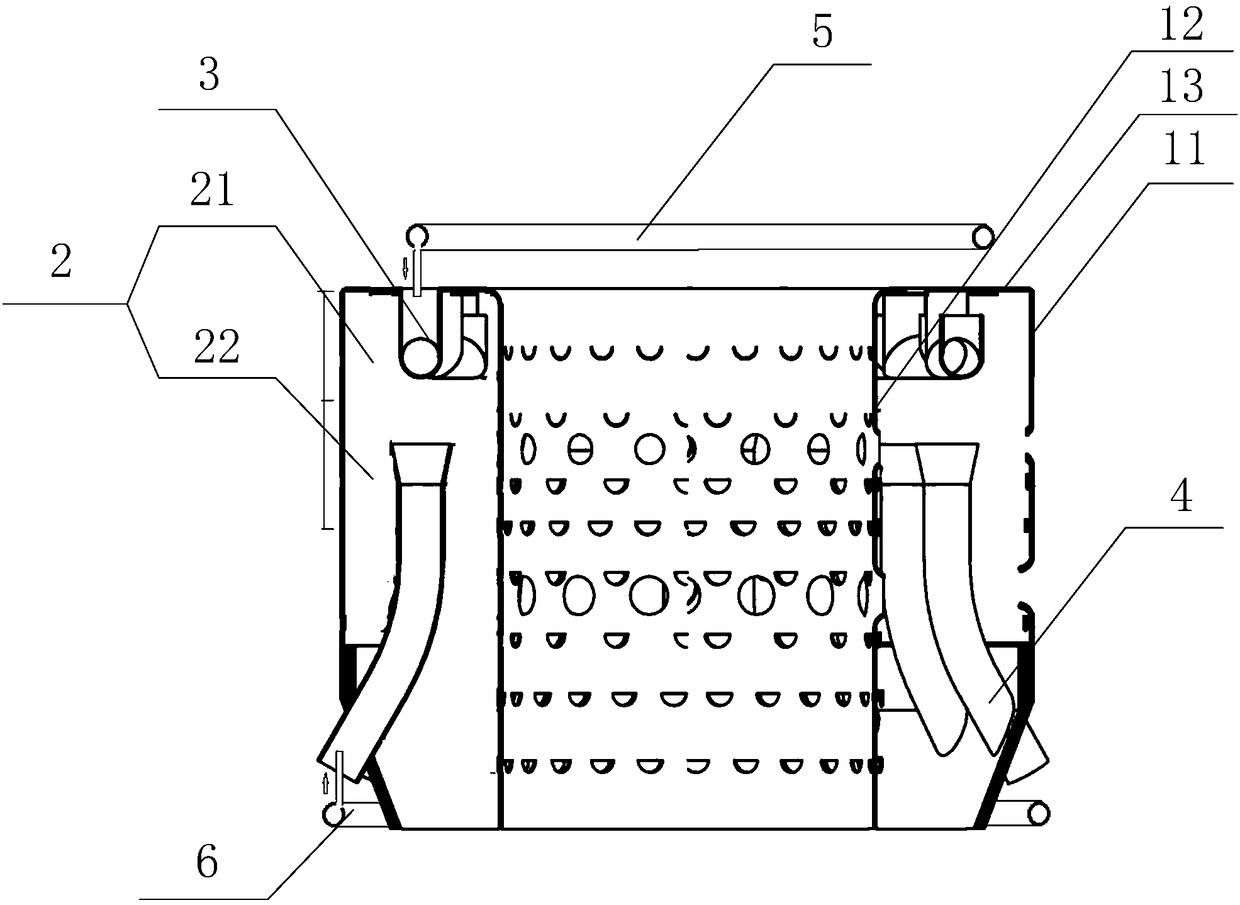

[0028] Example: such as figure 1 , figure 2 As shown, a combustion chamber for an engine includes a flame tube 1, a combustion chamber 2 is formed in the flame tube 1, and the front and rear parts of the flame tube 1 are respectively provided with a The first evaporation tube 3 and the second evaporation tube 4 for injecting fuel in the combustion chamber 2, one end opening of the first evaporation tube 3 is located in the combustion chamber 2, and the other end opening passes through the front end of the flame tube 1 and the fuel main pipe One end opening of the second evaporation tube 4 is located in the combustion chamber 2, and the other end opening passes through the rear of the flame tube 1 and communicates with the fuel main pipe. For different working conditions, only the first evaporation tube 3 is used to inject fuel into the combustion chamber 2 , or the first evaporation tube 3 and the second evaporation tube 4 are used to inject fuel into the combustion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com