High-speed rail roadbed fine-grained soil mixing amount upper limit determining method

A high-speed railway-based, method-determining technology, applied in measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems affecting the safety of trains, the allowable dosage is not comprehensive enough, changes, etc., and achieve excellent durability Effect

Active Publication Date: 2018-09-14

SOUTHEAST UNIV

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

High-speed railway trains are more sensitive to the deformation response of the subgrade under high-speed running conditions. A small subgrade frost heave will affect the smoothness and ride comfort of the railway, and more seriously affect the safety of the train and greatly increase the railway construction Department's line maintenance workload and maintenance costs

The problem of frost heaving is usually manifested as deformation of the subgrade, which will cause changes in the elevation of the track surface and cause unevenness of the track. In severe cases, it will affect the safety of train operation

[0004] High-speed railway-based fillers include gravel aggregates and fine-grained soil fillers. The microstructure of fine-grained soil fillers refers to the size, shape, spatial arrangement, and contact connection mode of coarse and fine particles and pores, which is one of the important factors that determine the nature of the project. It directly affects the frost heave sensitivity of the subgrade. Therefore, it is particularly important to determine the allowable amount of fine-grained soil in the subgrade filler. In the prior art, the indoor frost heave test is usually used to test the frost heave of the subgrade filler, so as to determine Whether the dosage of fine-grained soil meets the requirements, but judging the allowable dosage of fine-grained soil only by frost heave is not comprehensive enough, and it is impossible to accurately know the allowed dosage of fine-grained soil. Moreover, the test method is cumbersome and the test efficiency Low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

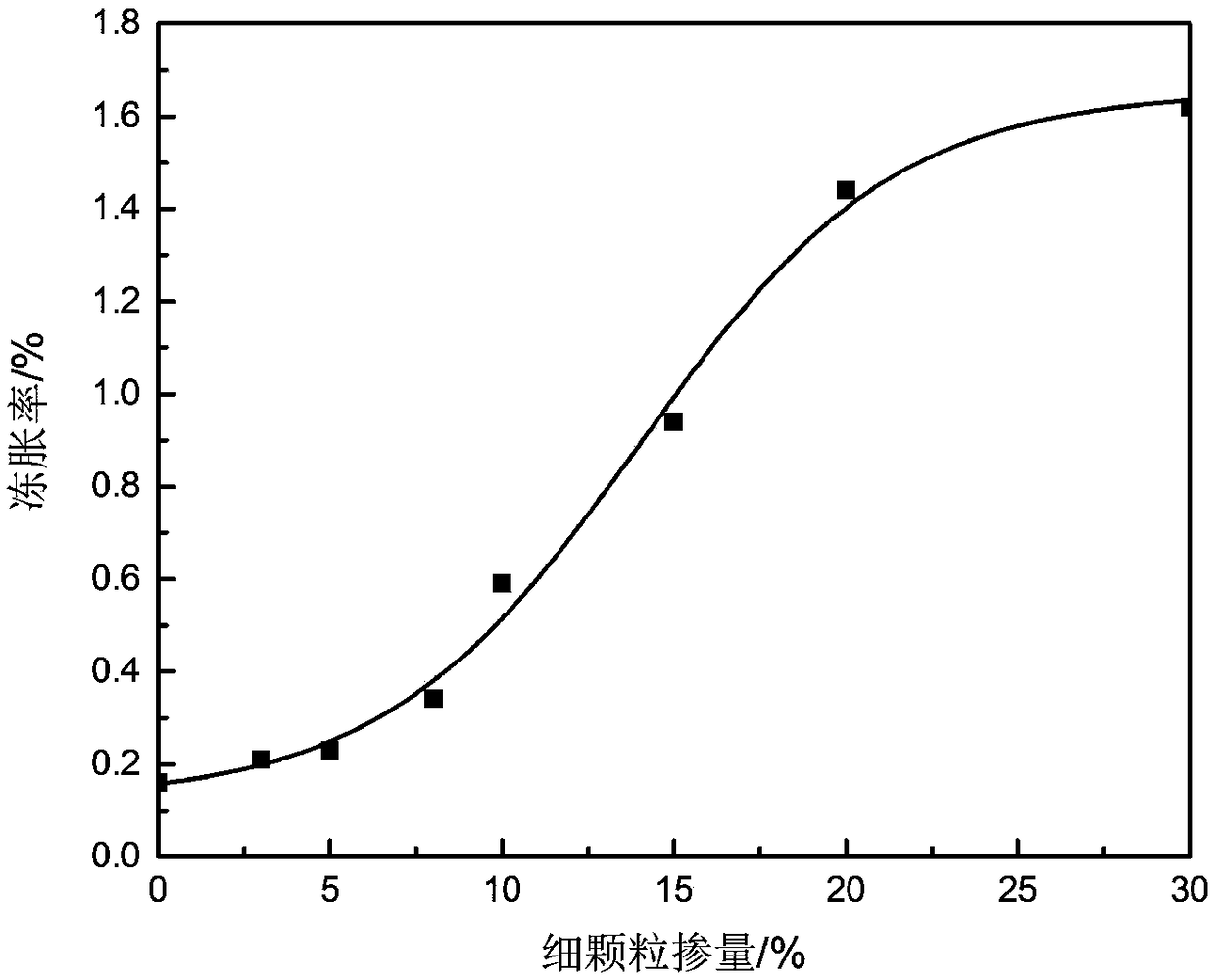

[0033] Weigh graded crushed stones of the same quality, take tap water and fine-grained soil with mass fractions of 3%, 5%, 8%, 10%, 15%, 20%, and 30% respectively, fully mix them and compact them into shape, temperature Cured for one day at 20±2°C and humidity above 90%, obtained roadbed filler samples with different fine-grained soil content.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

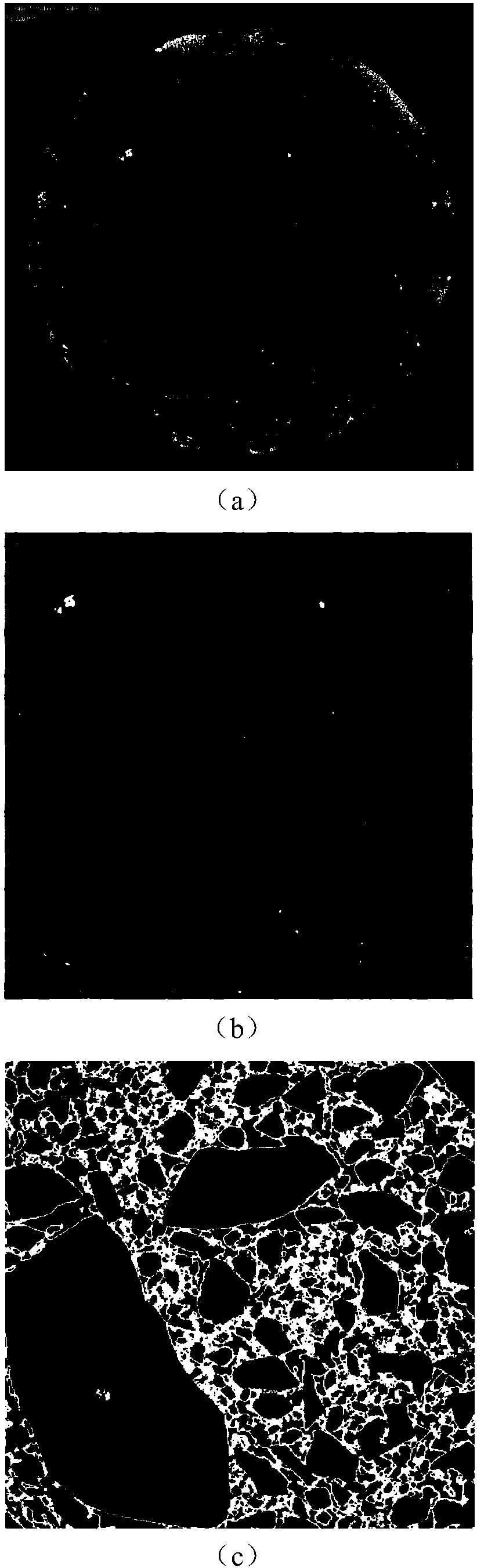

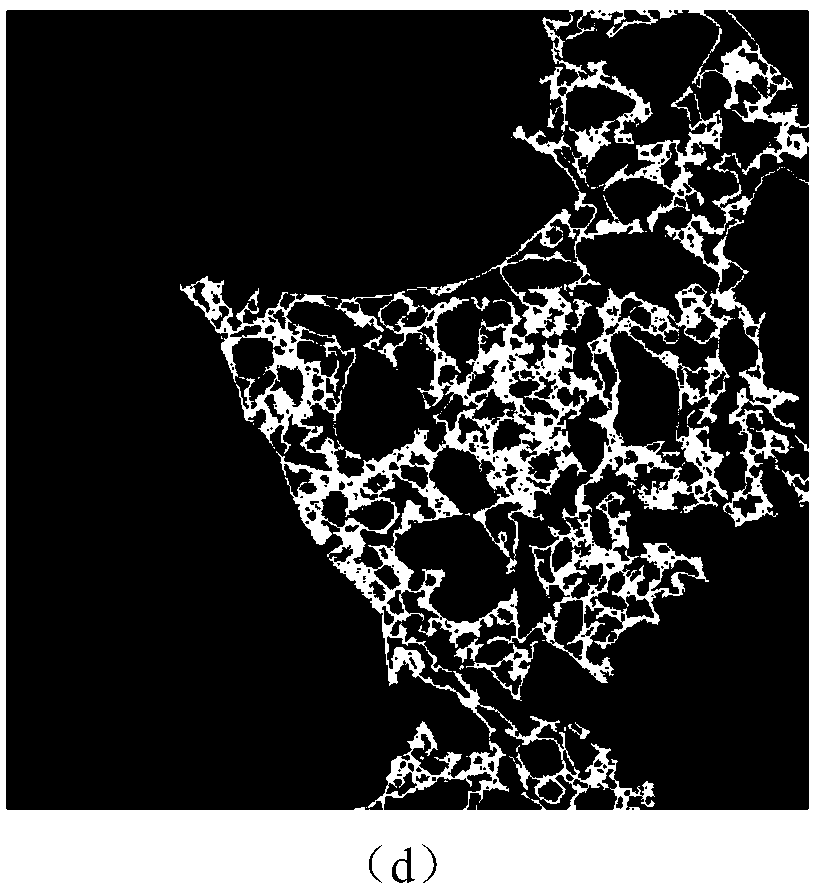

The invention discloses a high-speed rail roadbed fine-grained soil mixing amount upper limit determining method. The high-speed rail roadbed fine-grained soil mixing amount upper limit determining method comprises the following steps of (1) preparing filling samples different fine-grained soil content; (2) performing indoor frost heaving test to measure the frost heaving ratio of every filling sample; (3) performing X-ray tomographic scanning on the filling samples, counting and analyzing the area of communication and the box-counting fractal dimension of distribution of the fine-grained soilin every filling sample, and establishing function relations to fine-grained soil content; (4) comprehensively analyzing the change tendency of the fine-grained soil content along with the area of communication and the box-counting fractal dimension as well as the frost heaving ratio corresponding to different fine-grained soil content, determining the maximum mixing amount of fine-grained soil in roadbed filling. The high-speed rail roadbed fine-grained soil mixing amount upper limit determining method takes into consideration the influence of distribution of fine-grained soil filling and microscopic pores, and through a porous structure microscopic analyzing method and an image processing method, can accurately acquire the fine-grained soil mixing amount upper limit meeting the requirements of non-frost heaving filling, thereby being favorable to developing high-speed rail roadbed filling with excellent durability.

Description

technical field [0001] The invention provides a method for determining the upper limit of fine-grained soil content in high-speed railway foundation fillers, and belongs to the field of filler construction for high-speed railway foundations. Background technique [0002] High-speed railway has become the first choice of mass transportation in a resource-saving and environment-friendly society due to its outstanding characteristics of high operating speed, low energy consumption, and low environmental pollution. Northeast China has a high latitude, complex topography, and a wide distribution of seasonal frozen soil areas. Most of the high-speed passenger dedicated lines such as Haqi and Harbin are in such a severe cold environment. [0003] The maximum frost heave of the subgrade in severe cold environment can reach 8mm, which seriously affects the smoothness of the subgrade. High-speed railway trains are more sensitive to the deformation response of the subgrade under high-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N23/046

CPCG01N23/046

Inventor 蒋金洋曹霄宇王凤娟赵国堂武胜萍胡翔宇

Owner SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com