Transportation system of unmanned restaurant

A transportation system, restaurant technology, applied in the direction of table utensils, tables, home utensils, etc., can solve problems such as time waste, and achieve the effect of increasing the running speed, narrowing the gap, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below according to the drawings and embodiments.

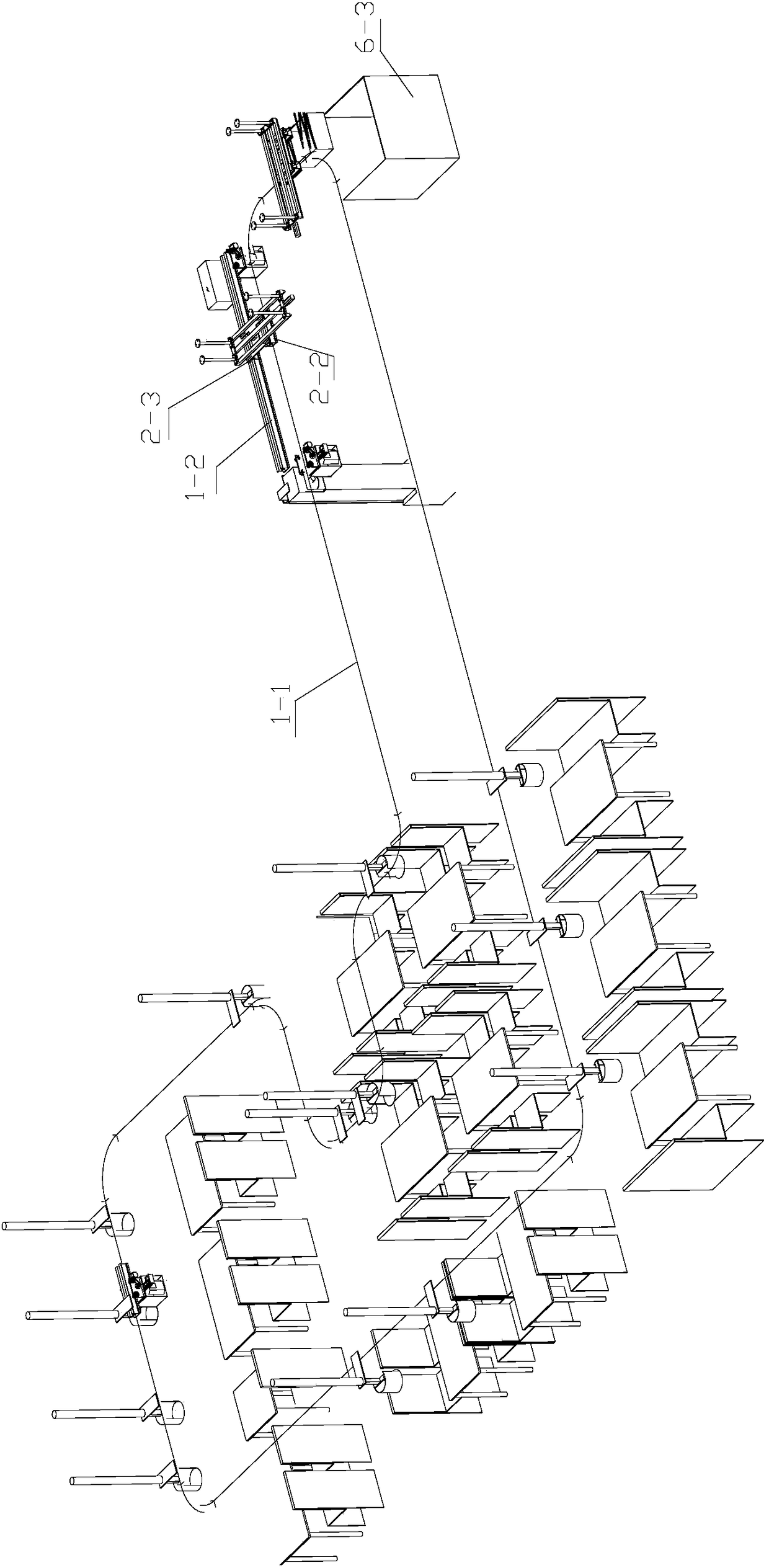

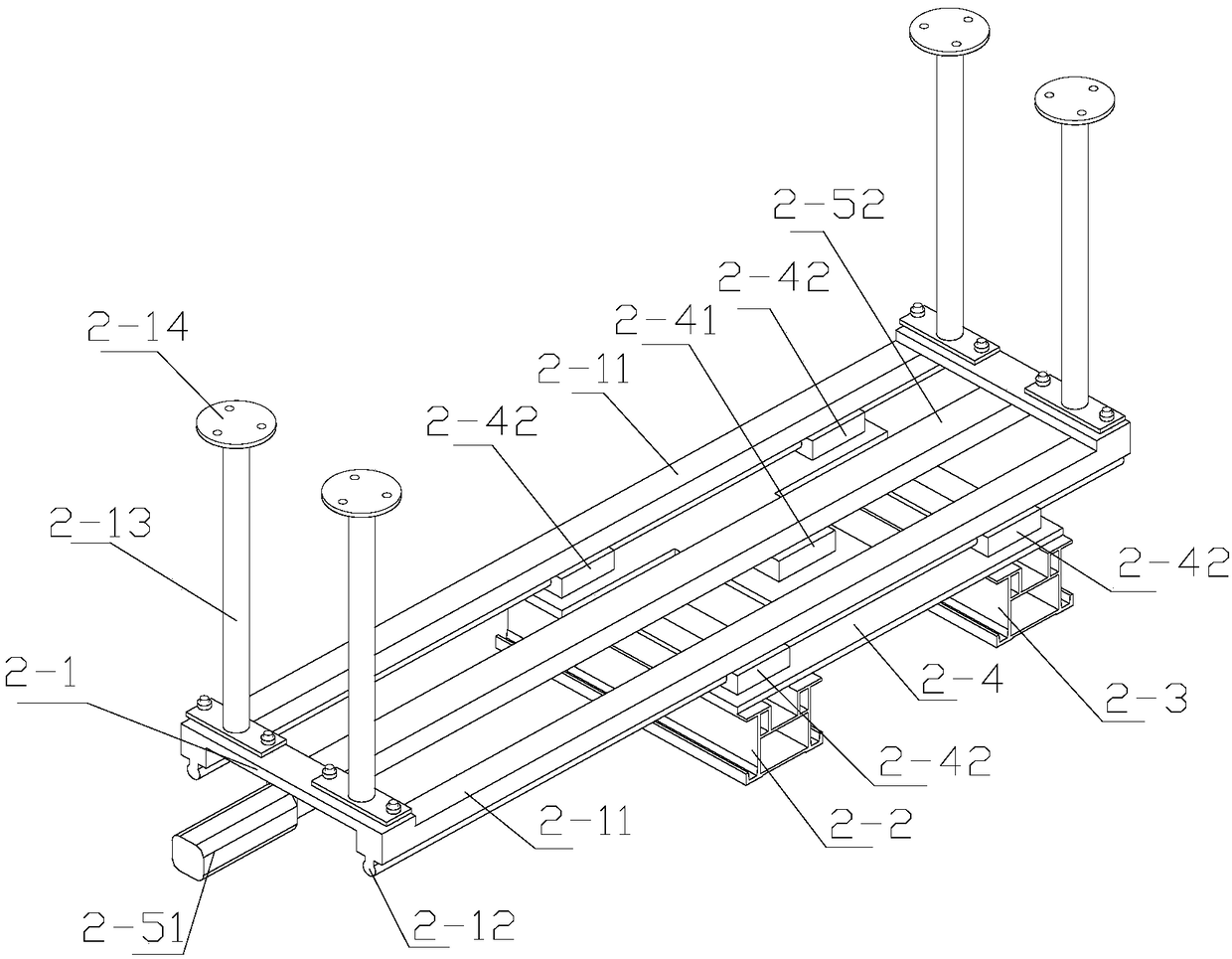

[0036] The transportation system for unmanned restaurants, including: track devices, track changing devices, multiple dining cars, and recovery devices.

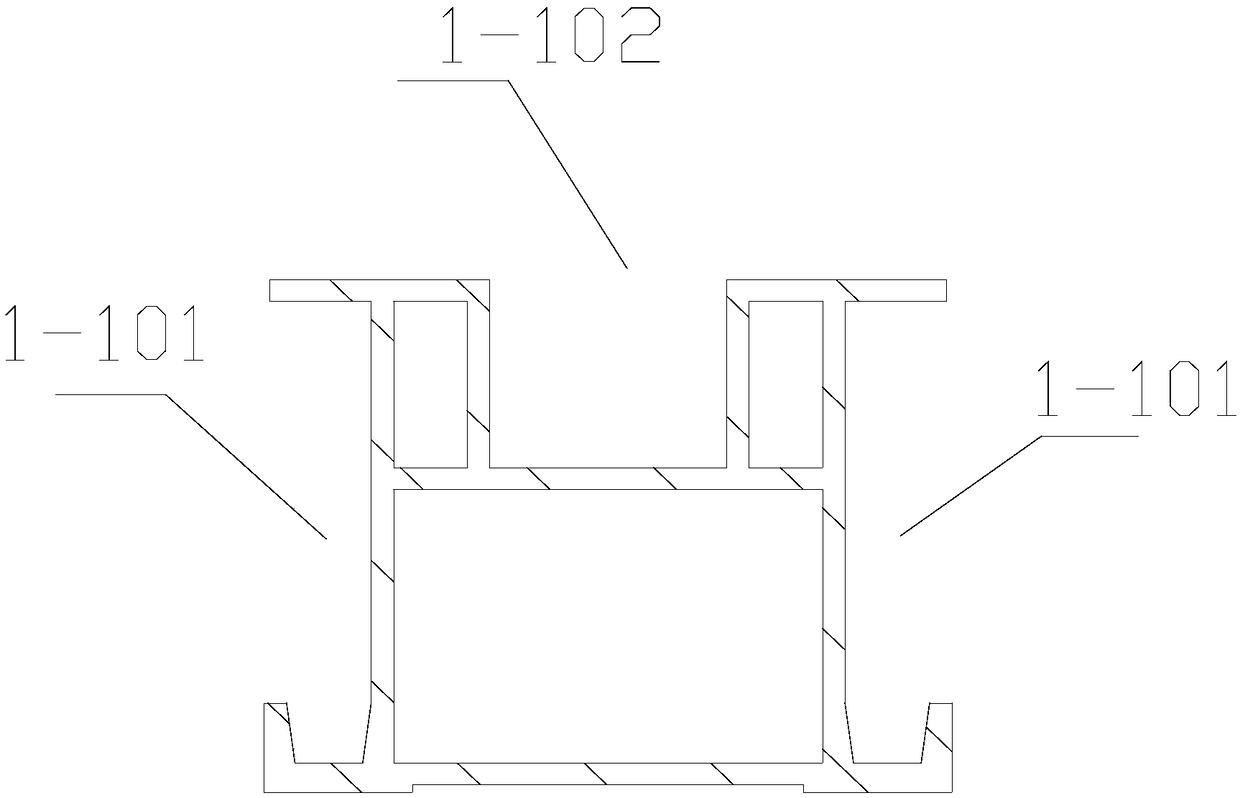

[0037] figure 1 It is an overall schematic diagram of the transportation system of the unmanned restaurant of the present invention, figure 2 It is a schematic diagram of the cross-sectional structure of the conveying track / outer track of the present invention, referring to figure 1 , figure 2 , a track device, comprising a delivery track 1-1 and an outer track 1-2, the left and right sides of the above-mentioned delivery track 1-1 and the above-mentioned outer track 1-2 are set as guide grooves 1-101 for transportation, and the top is routed The groove 1-102 is used for setting lines, etc. For the conveying track 1-1, it is a closed track with multiple bends, and the above-mentioned outer track 1-2 is a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com