Horizontal transverse moving type automatic box switching device

A technology of driving device and shifting device, which is applied in the field of machine tools, can solve problems such as cumbersome structure, large space occupation, and tool breakage, and achieve the effects of simple and reliable structure, prevention of safety hazards, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

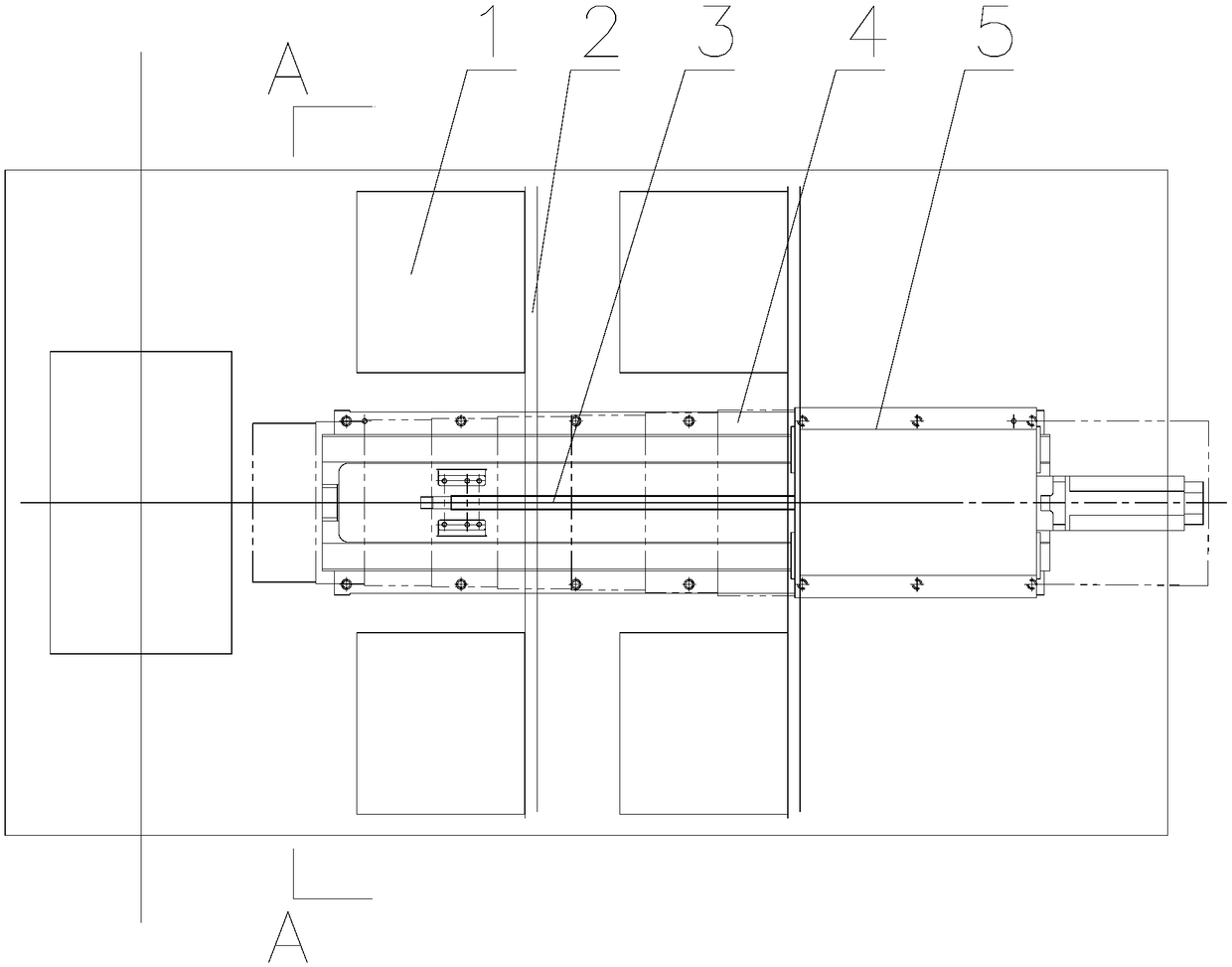

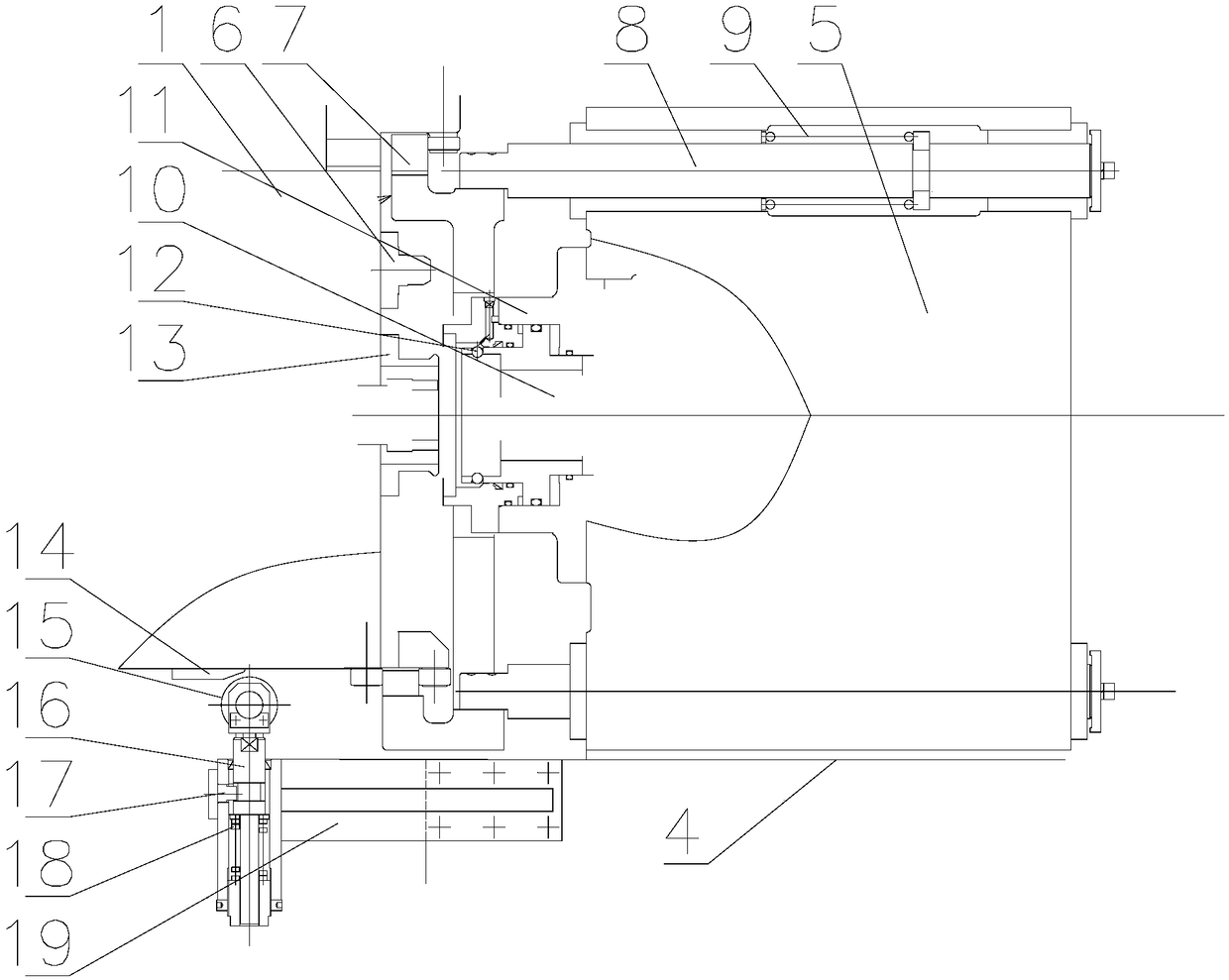

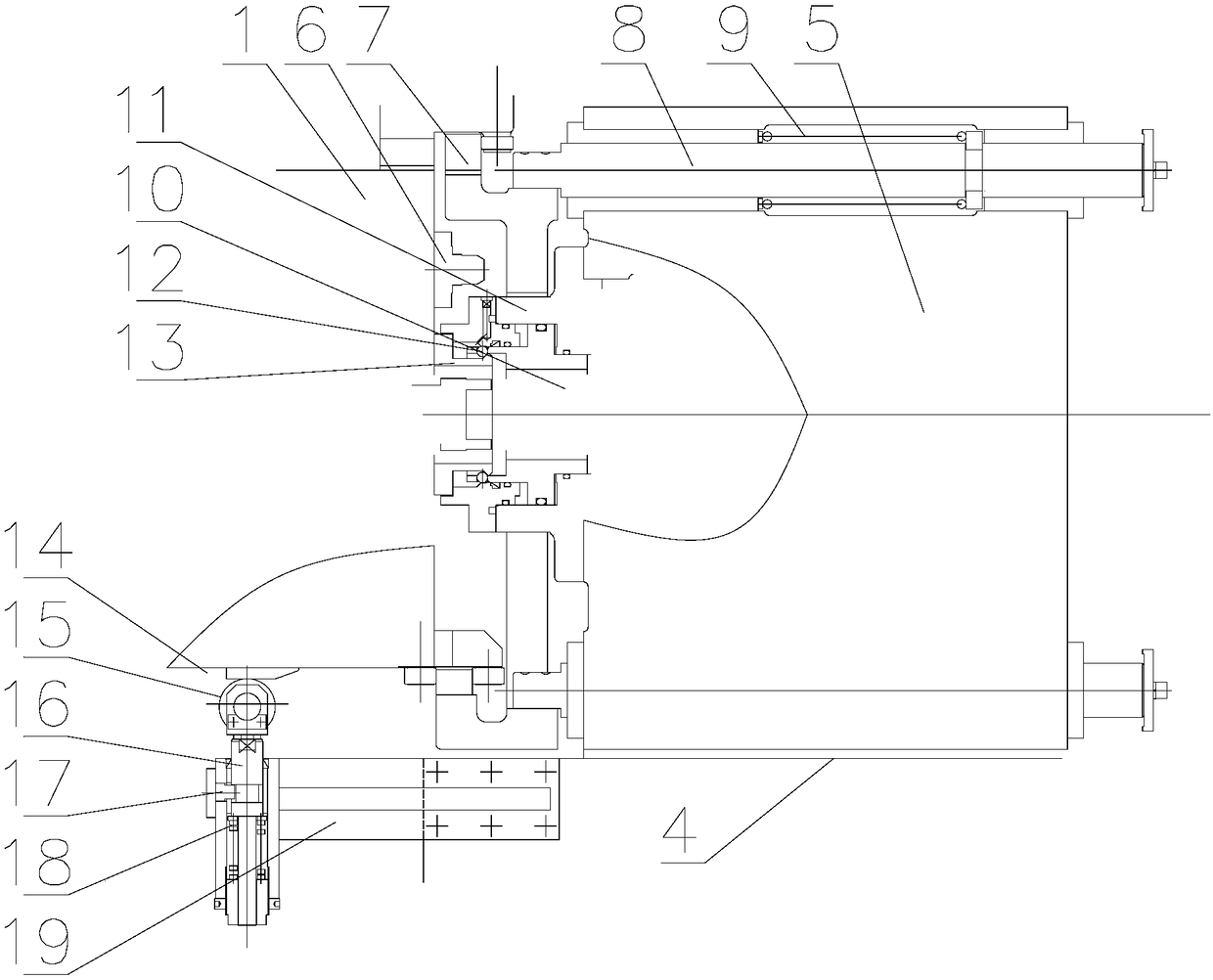

[0036]The specific embodiment of the present invention is shown in the accompanying drawings, the horizontal traversing automatic box changing device adopts the box changing mode of horizontal traversing, including: machine tool base, feed slide table 4, box changing shifting device 2, driving device 5 (comprising guide device, interface device and clamping device), auxiliary support for changing boxes and 4 multi-axis boxes 1; the main body of the driving device 5 is installed on the saddle of the feed slide 4 in the middle of the machine base; 4 multi-axis boxes 1 It is installed on the shifting device 2 and can be driven by the servo shaft to move horizontally; after the multi-axis box 1 moves horizontally into the upper position of the feed slide 4, it is suspended on the guide device and installed on the feed slide through the latch. The driving device 3 on the 4 is positioned and connected; the driving device 5 moves forward on the feed slide 4 and is connected with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com