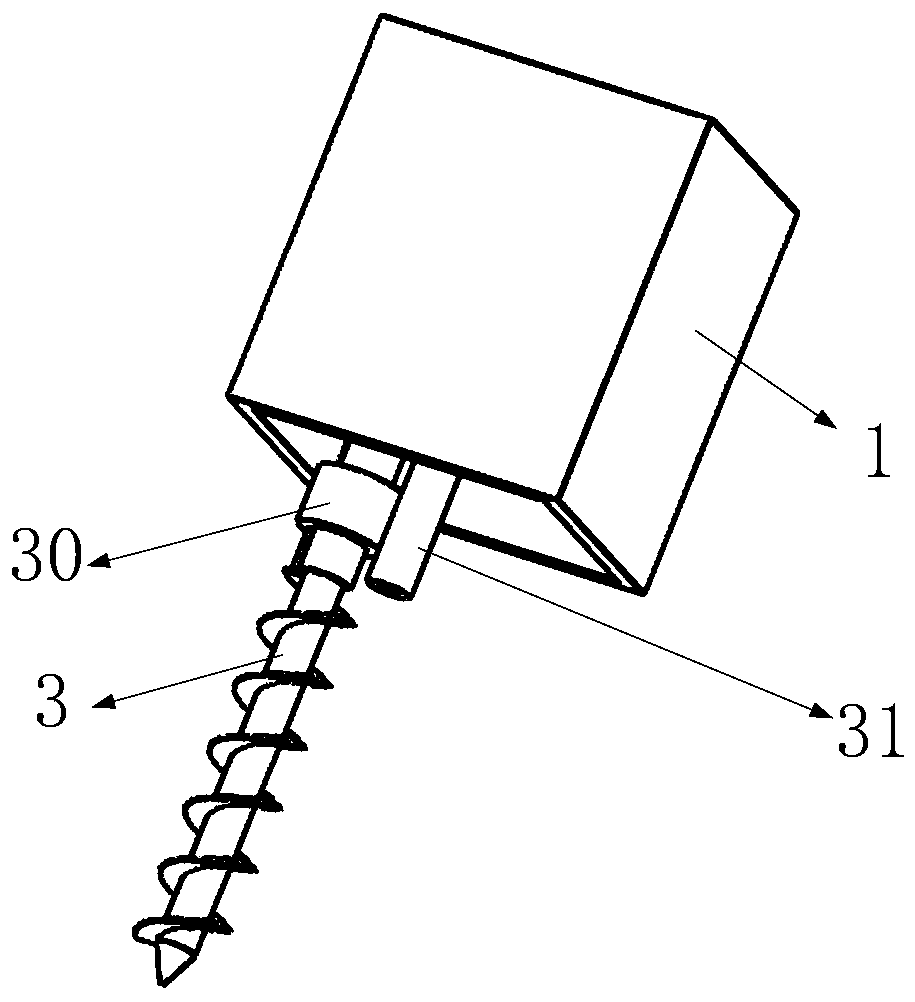

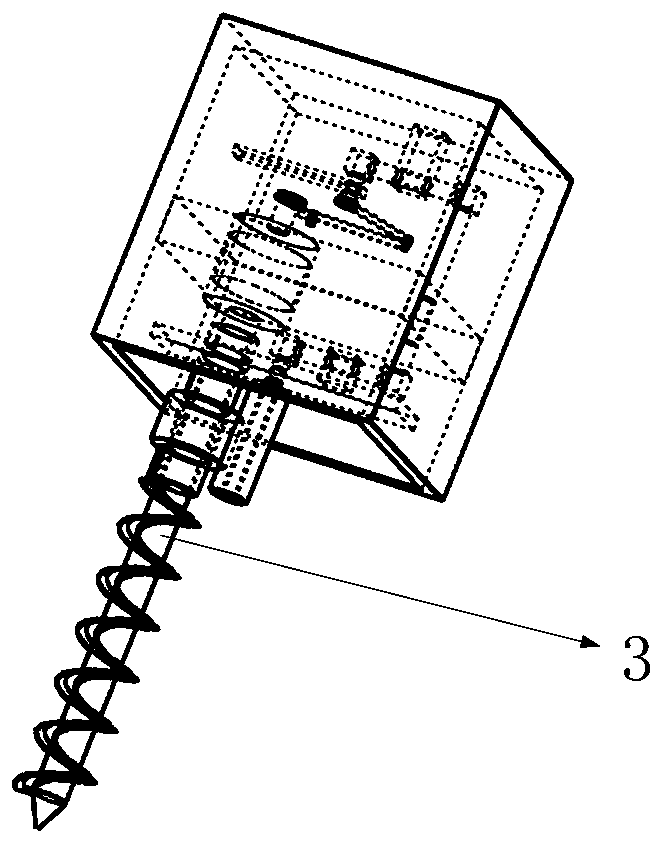

anti-blocking auger

An auger and helical blade technology, applied in the field of anti-clogging auger, can solve problems such as affecting the drilling progress and easily blocking clay, and achieve the effects of being beneficial to the drilling progress, reducing the weight and having a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

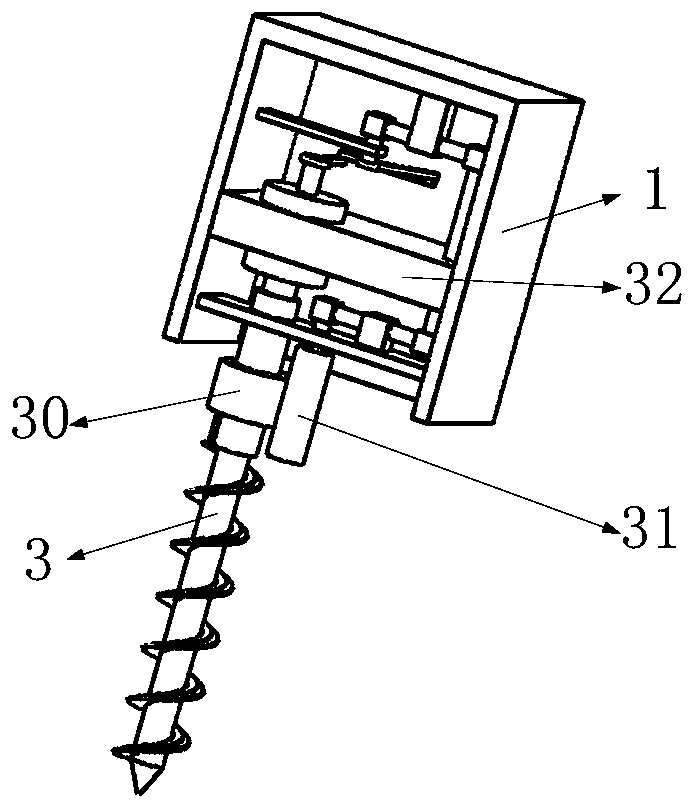

specific Embodiment approach

[0050] Specific embodiments: after the motor 2 starts, the motor 2 drives the drill shaft 3 and the drive shaft 38 to rotate through the motor 2 shaft, and the drill shaft 3 drives the first helical piece 19 to rotate, and the drill shaft 3 and the drive shaft 38 always keep rotating at the same speed; According to the working principle of the variable speed double crank mechanism, the drive shaft 38 cannot always keep rotating at the same speed as the first shaft 43, and the speed of the first shaft 43 will be faster than the drive shaft 38 and slower than the drive shaft 38 during the rotation process. situation, then the first shaft 43 passes through a bevel tooth combination, the second shaft 44, the second bevel tooth combination 40, the third shaft 45, the third bevel tooth combination 41, the fourth shaft 46, the fourth bevel tooth combination 42 and the second bevel tooth combination The five-axis 47 drives the drive gear 31 to rotate at a variable speed, and there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com