Method for determining thicknesses of gaskets for assembling roll to bearing pedestal

A method for determining bearing housings, which is applied to the rigid support of bearing components, bearing elements, shafts and bearings, etc., can solve the problems of low efficiency, unsafe and cumbersome bearing housing components and rolls, etc., and achieve simplified assembly steps, The effect of reducing repeated hoisting and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

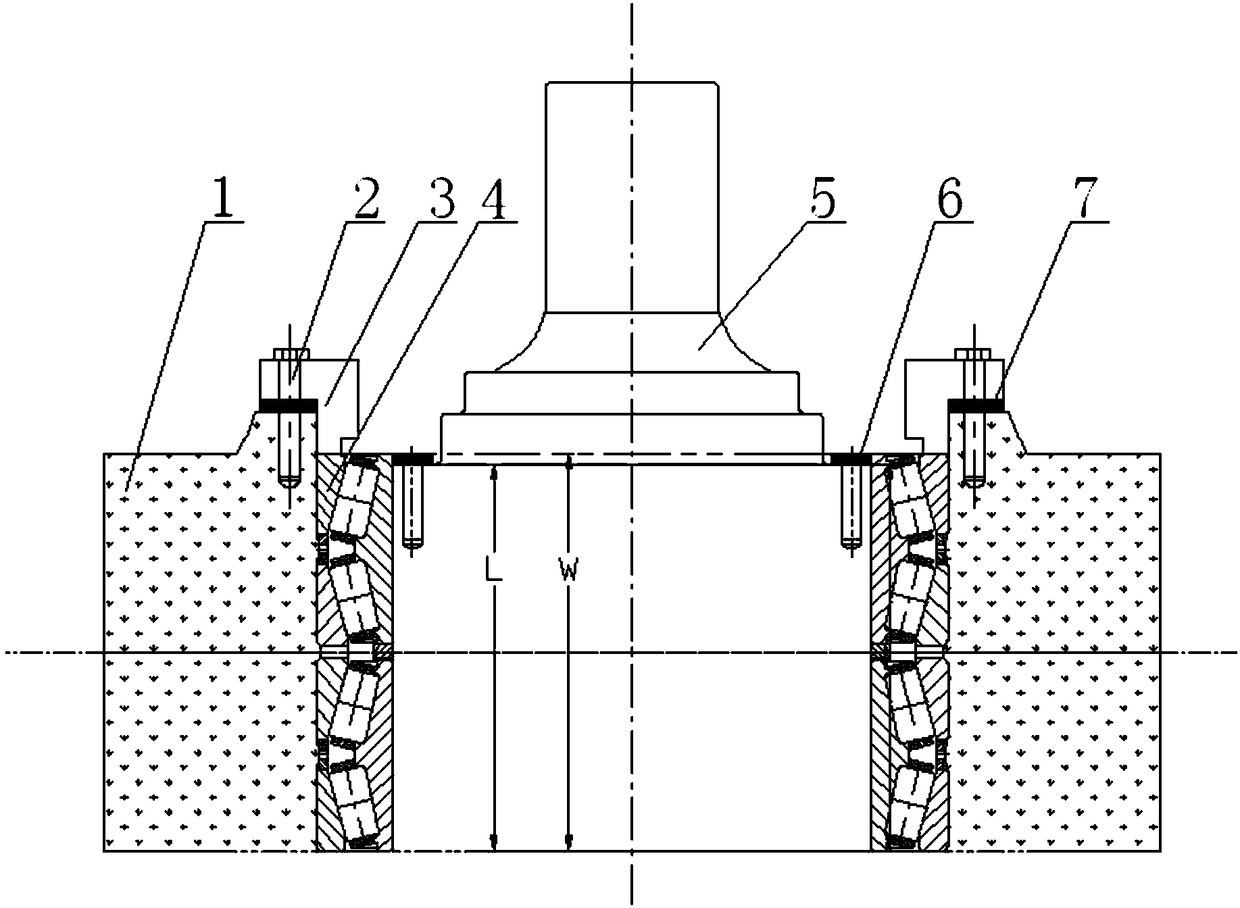

Image

Examples

Embodiment

[0020] The wet skin pass mill of a cold rolling galvanizing line is a single-stand four-high rolling mill, and the bearings are single-stand galvanized skin pass machine bearings. The radial and axial gaskets are determined as follows:

[0021] The axial clearance G given during design is 0.2~0.4, and the middle value is 0.3 during calculation. After calculation and statistics, the range of λ is 0.063~0.12, and the unit of all involved values is mm.

[0022] (1) Assemble the lower box on the operation side of the support roller

[0023] Box No.: 23569090 2#013-2

[0024] Rack position: Operator side down

[0025] Roll number: B04-006

[0026] Bearing number: CZ2641461-004

[0027] Original width of bearing inner ring: 480.135

[0028] a. Bearing assembly in the bearing housing, install the bearing gland, and use the "finger tightening" method to tighten the bolts.

[0029] b. Measure the distance between the gland and the end face of the bearing seat, measure 6 points: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com