Pipe jacking machine capable of improving safety performance

A technology of safety performance and pipe jacking machine, which is applied in the directions of mechanical equipment, pipeline laying and maintenance, pipes/pipe joints/pipe fittings, etc. It can solve the problems of low safety performance and achieve the effect of simple structure and improved safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

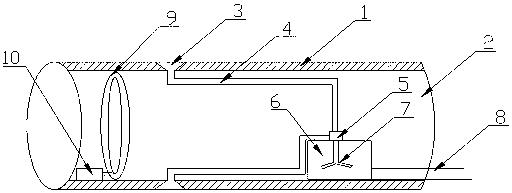

[0022] Embodiment 1: as figure 1 As shown, a pipe jacking machine for improving safety performance includes a shell 1 and a pipe jacking head 2, the shell 1 sets the pipe jacking head 2 inside; the pipe jacking head 2 is provided with a reducing The friction mud mixing chamber 6 and the escape air bag device; the thixotropic mud mixing chamber is placed at the bottom of the pipe jacking head 2 and 6 is connected to the shell 1 through the grouting pipe 4; the escape air bag device is detachably connected to the pipe jacking machine On the inner wall of the head 2; on the outer wall of the housing 1, several grouting ports 3 are evenly arranged; one end of the grouting pipe 4) is connected to the grouting port 3.

Embodiment 2

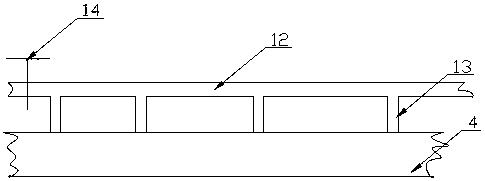

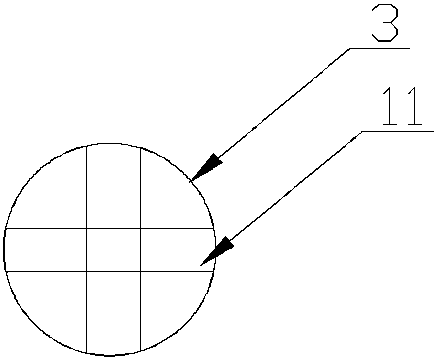

[0023] Embodiment 2: as figure 2 and 3 As shown, the section of the grouting port 3 is trumpet-shaped; the grouting port 3 is also provided with a diversion protrusion 11; the diversion protrusion 11 spans the grouting port 3 and covers part of the grouting port 3 ; The cross-section of the diversion protrusion 11 is cross-shaped.

Embodiment 3

[0024] Embodiment 3: as figure 1 As shown, the thixotropic mud mixing bin 6 is provided with a stirrer 7 and the thixotropic mud mixing bin 6 is connected with a water inlet pipe 8; the top of the thixotropic mud mixing bin 6 is provided with a slurry outlet and the The slurry outlet is connected to the grouting pipe 4; the slurry outlet is provided with a syringe pump 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com