Protecting hood for air outlet of vacuum pump

A technology of vacuum pump and protective cover, applied in the direction of pump, pump components, variable capacity pump components, etc., can solve the problem of lack of protective measures in the exhaust port of electric vacuum pump, and achieve long service life, prevent a large number of back suction, reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

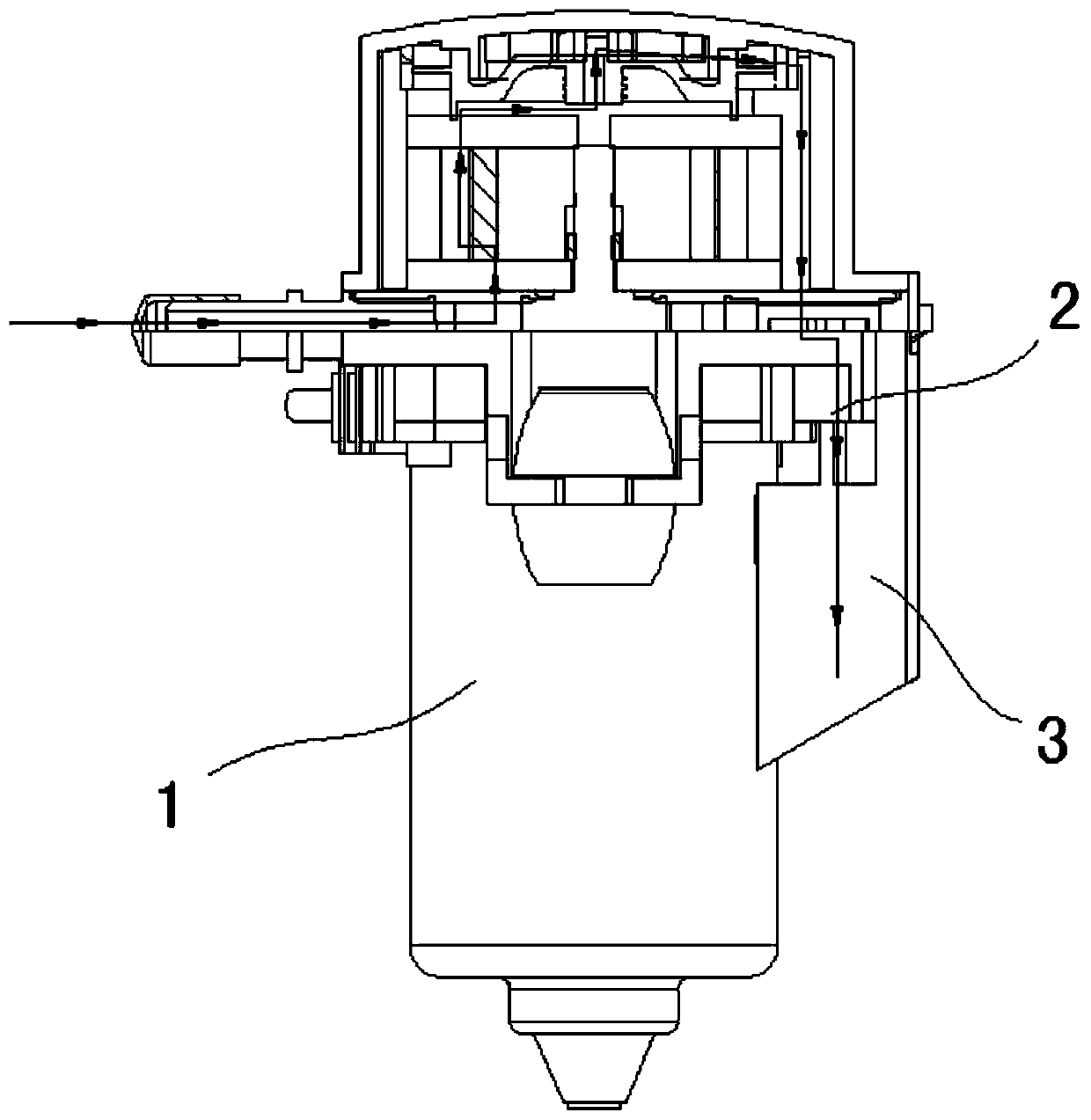

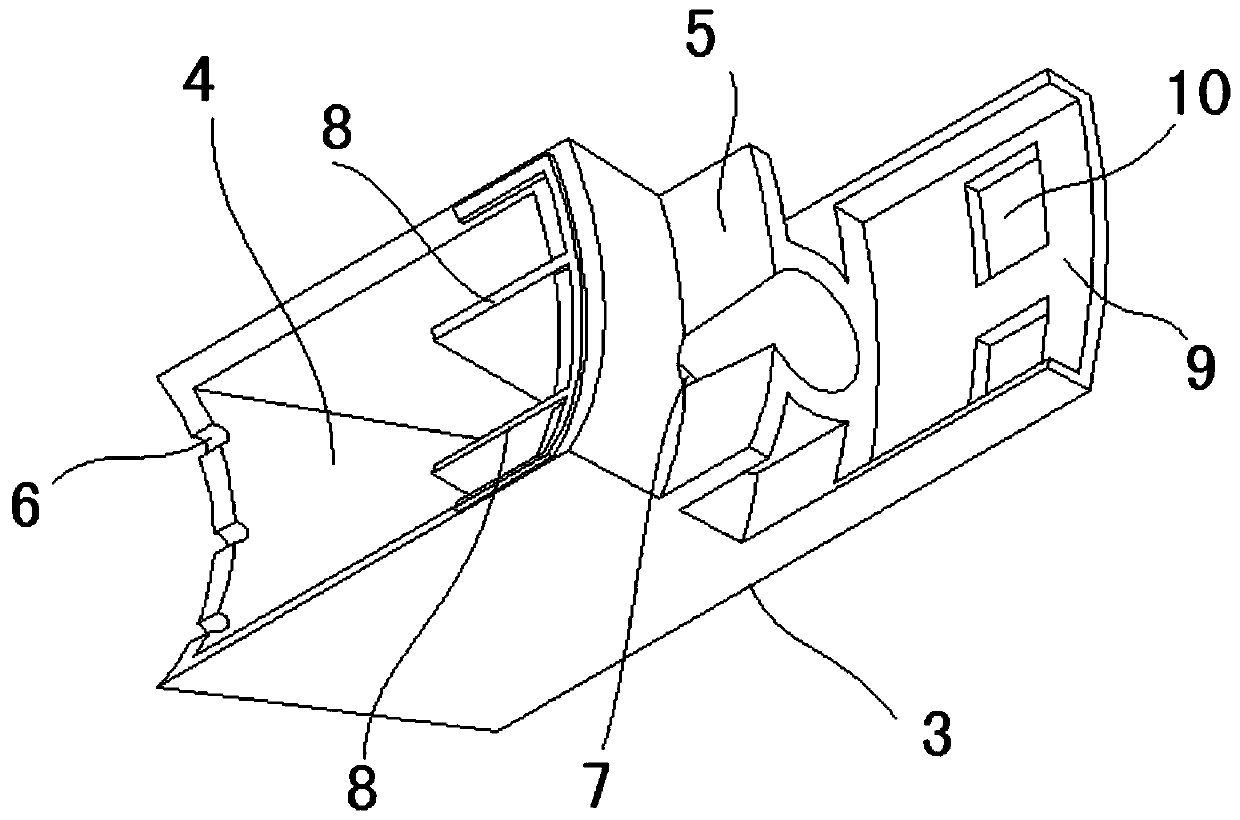

[0020] Vacuum pump outlet protective cover 3 such as figure 1 , fixed with the vacuum pump 1, the exhaust port 2 of the vacuum pump 1 is in close contact with the exhaust seat 5, and the gas discharged from the exhaust port 2 is buffered in the buffer box 4 and then discharged through a plurality of exhaust holes 6, which is safe and low in noise. The air hole 6 is located at the bottom of the protective cover 3, and the sputtering liquid retained in the gas discharged by the vacuum pump 1 can be discharged from the bottom exhaust hole 6 in droplets after being accumulated in the buffer tank 4; two partitions 8 separate the upper part of the buffer tank into three small chambers, the through hole 7 is located in the middle chamber, and the small chambers on both sides can keep the middle chamber warm, mud-proof, waterproof, frost-proof, and freeze-proof. When sucking, the small chambers on both sides can also prevent most of the airflow from directly rushing into the exhaust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com