New energy button battery pack

A battery pack, new energy technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of increasing the volume of new energy batteries, complex heating device structure, slow heating of battery cells, etc., and achieve connection stability. Good, high production efficiency, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

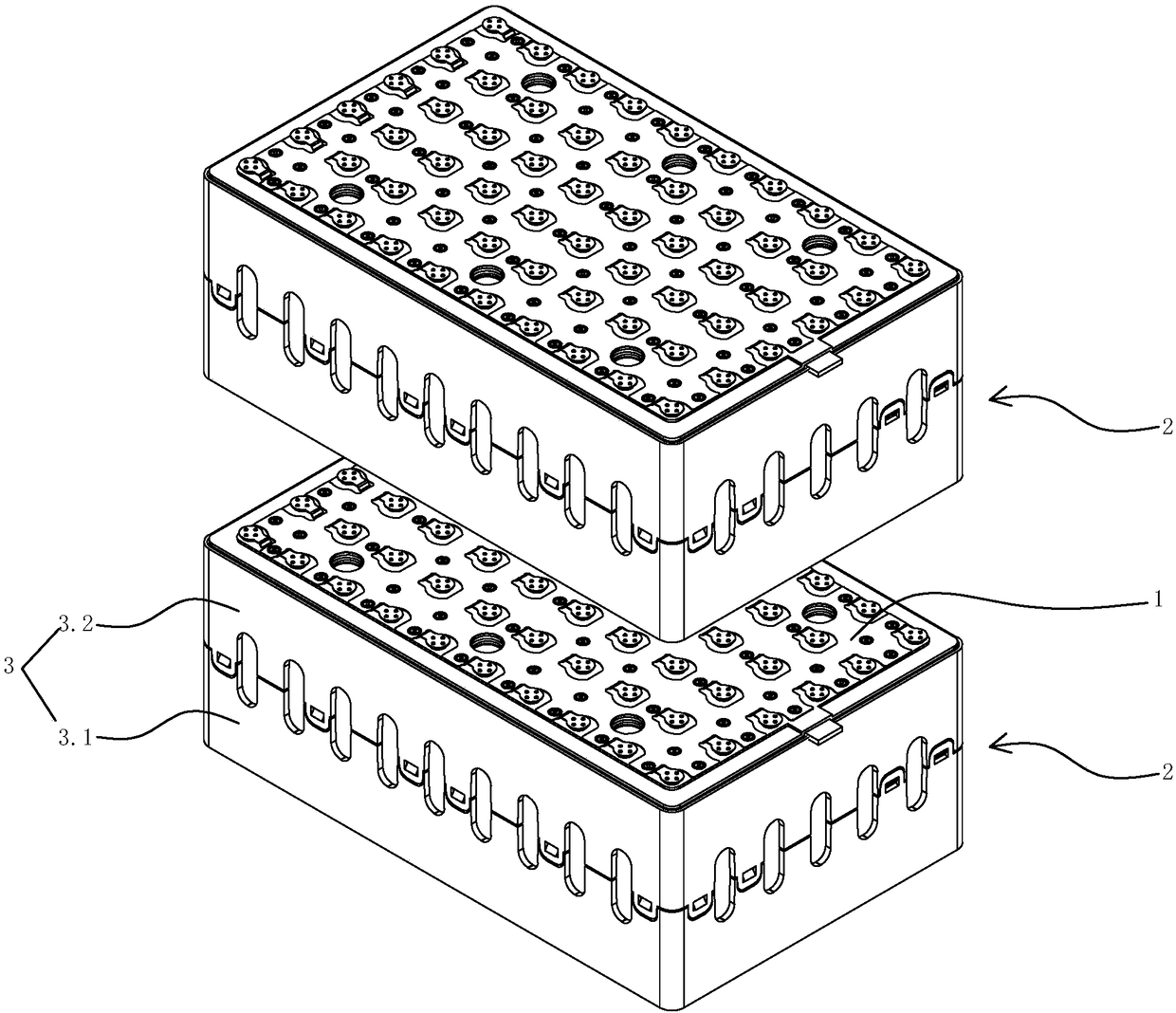

[0058] Embodiment 1: as figure 1 As shown, a new energy button battery pack includes a number of unit battery modules 2 sequentially connected in series through a connecting plate 1 .

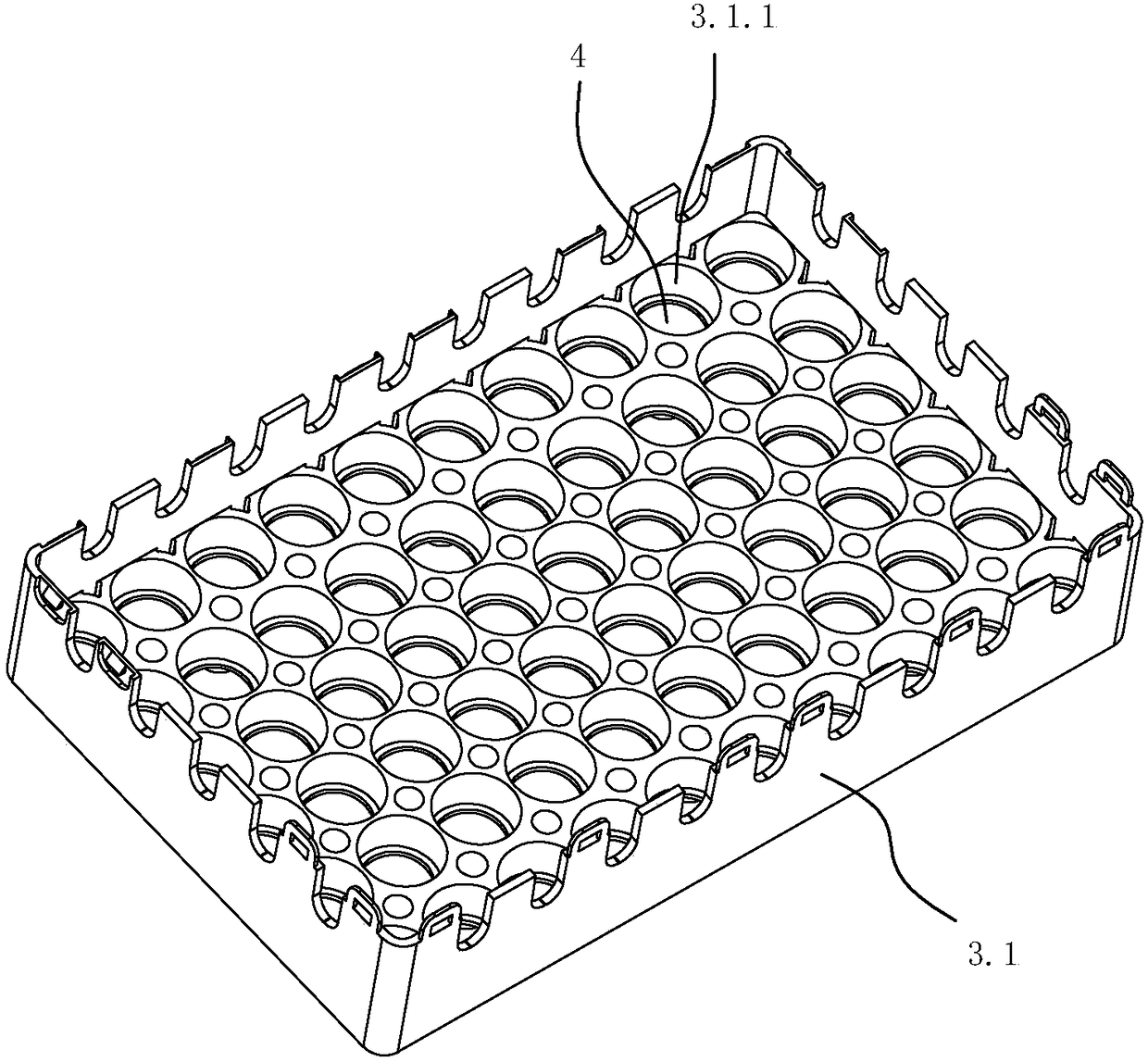

[0059] like Figure 6 As shown, the unit battery module includes a battery box 3 and a plurality of batteries 5 positioned and installed in the battery box in a matrix arrangement. The battery of this embodiment is a cylindrical lithium battery.

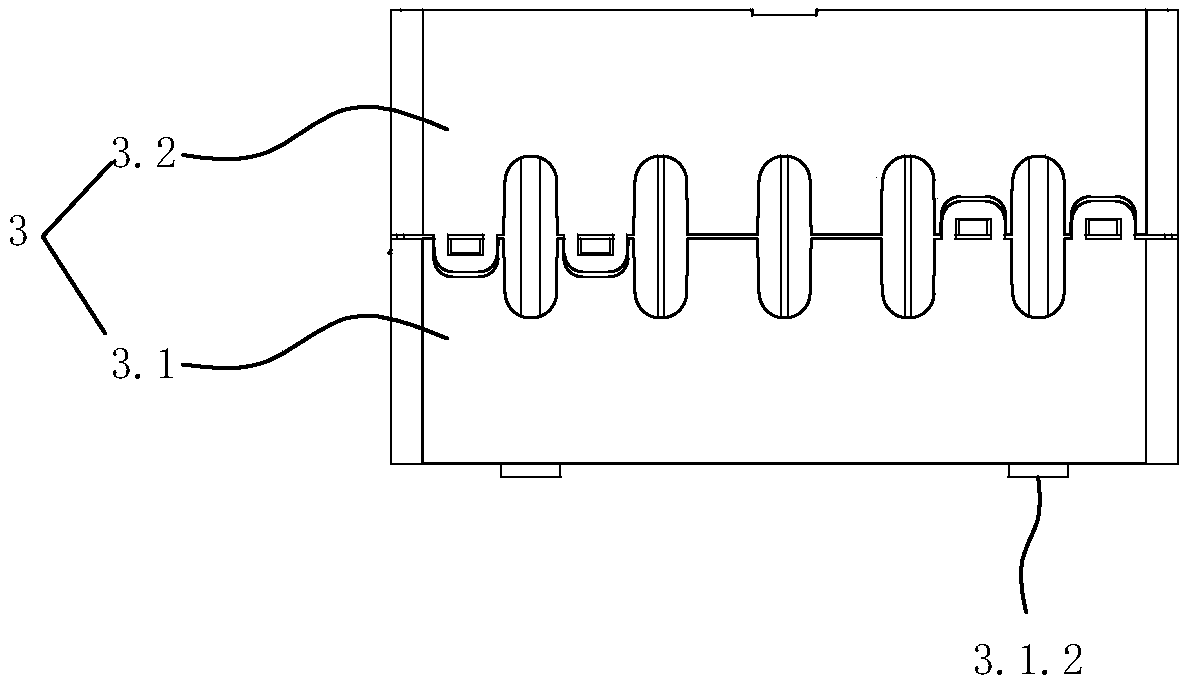

[0060] like figure 1 , figure 2 , image 3 As shown, the battery box includes a lower box body 3.1 and an upper box body 3.2, and the upper box body and the lower box body are connected by buckles. There are several ventilation holes on the side of the battery box. The top surface and the bottom surface of the battery box are all provided with the extreme connecting holes 4 corresponding to the extremes of the battery one by one, specifically, the top surface of the upper box body and the bottom surface of the lower box body are all provided wi...

Embodiment 2

[0074] Embodiment 2: The specific structure of the new energy button battery pack of this embodiment refers to Embodiment 1, the difference is that:

[0075] like Figure 8 , Figure 9 As shown, the new energy button battery pack also includes several self-adaptive separation devices 1.7 arranged on the conductive plate. The two conductive plates are connected by riveting through a riveting structure.

[0076]An elastic electrical connection piece 1.6 for electrically connecting the two conductive plates is also provided in the heating plate accommodation chamber. The elastic electrical connecting piece is in Z shape. One end of the elastic electrical connecting piece is fixed on the bottom surface of the heating plate receiving groove of one conductive plate, and the other end of the elastic electrical connecting piece elastically abuts against the bottom surface of the heating plate receiving groove of the other conductive plate.

[0077] The riveting structure includes ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap