Trench digging and soil covering mechanism for direct seeding in dry rice fields

A technology for direct seeding and direct seeding in dry fields, which is applied to sowing seeders, planter parts, and excavation/covering of trenches, etc., can solve problems such as inability to effectively cover grain seeds, poor direct seeding effect in dry fields, and delay in farming time, and achieve the effect of covering soil. Ideal, low maintenance cost, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

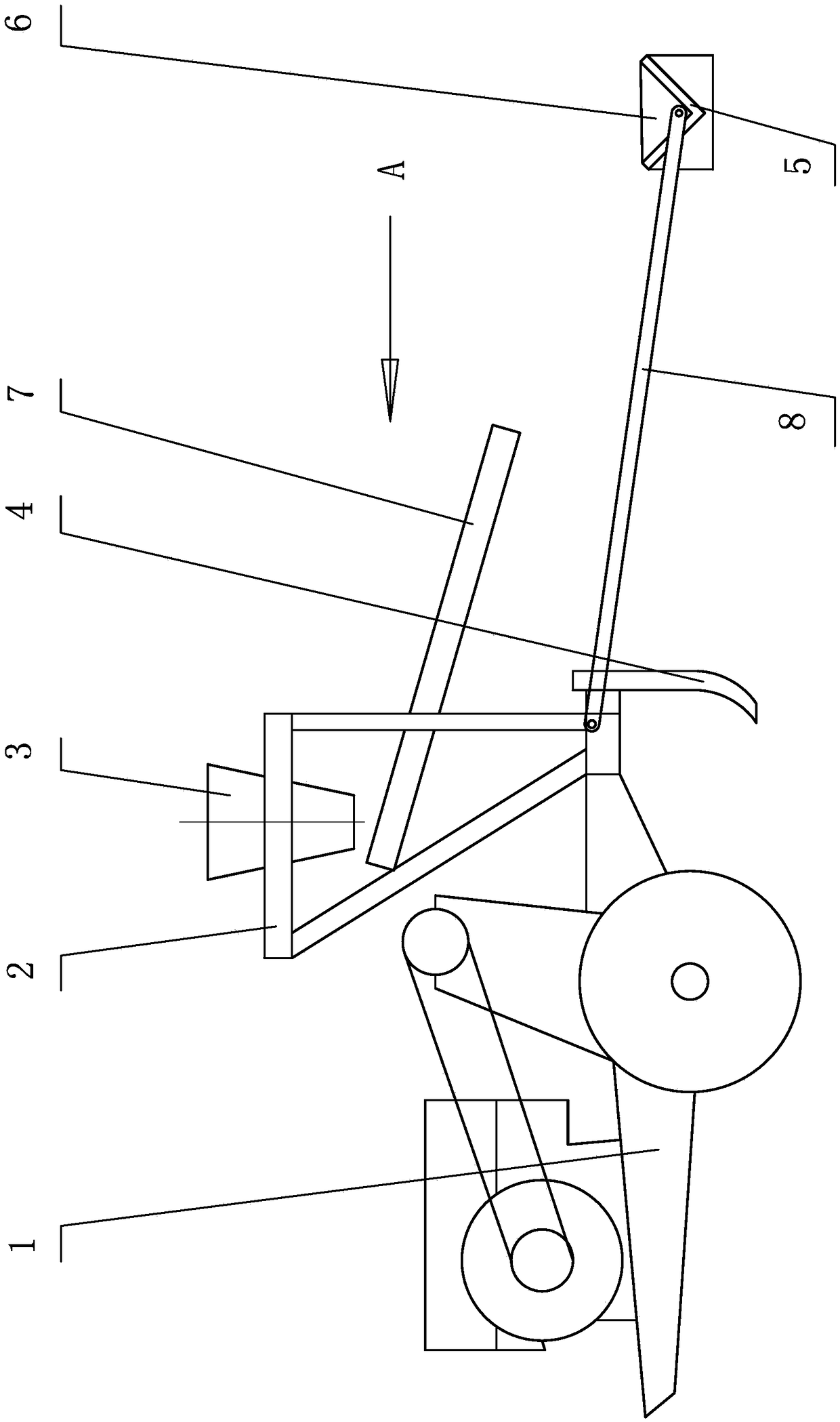

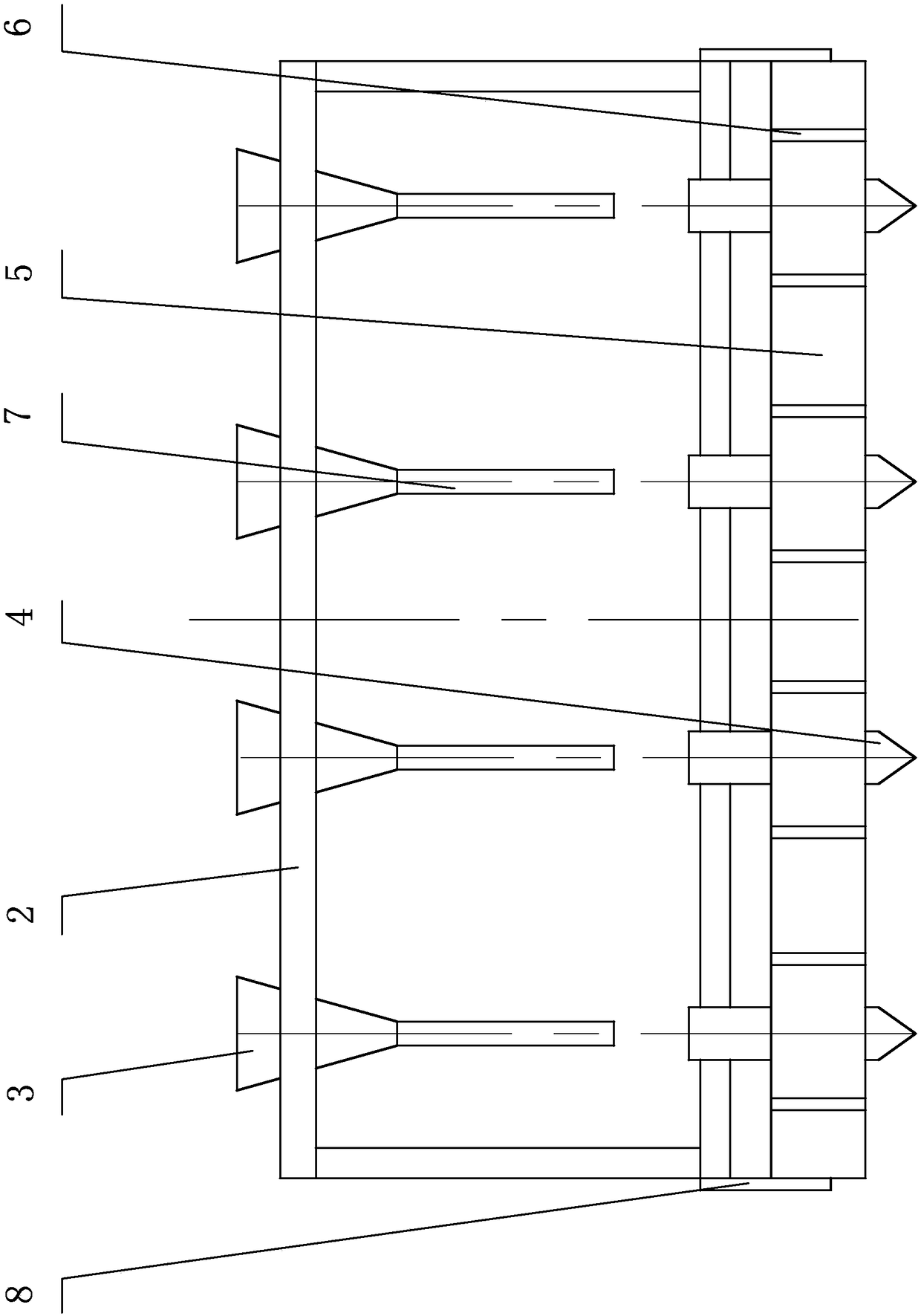

[0017] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0018] The present invention is used for the ditching soil-covering mechanism of paddy field live broadcasting, and its structure comprises the paddy direct seeding frame 2 that is installed on the rear end of micro tillage machine 1 frame, and described paddy direct seeding frame 2 is installed with 4 grain hoppers 3, 4 Ditch opener 4, 4 valley row troughs 7 and 4 secondary earth covering plates 6, every pair of earth covering plates 6 are two pieces of left and right symmetry.

[0019] 4 grain hoppers 3 are installed on the front upper part of the rice direct seeding frame 2, and the distance between the 4 grain hoppers 3 can be adjusted left and right, and the conventional arrangement is that the 4 grain hoppers 3 are evenly spaced; On the rear side of the bottom of the frame 2, the conventional arrangement is that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com