A vegetable automatic dehydration device and method

A dehydration device and vegetable technology, applied in the fields of application, food science, food processing, etc., can solve the problems of low degree of automation, dehydration of burned vegetables, incompleteness, etc., and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The content of the present invention will be specifically described below in conjunction with the figures, but the following examples are only used to illustrate the present invention, and are not intended to limit the scope of the present invention.

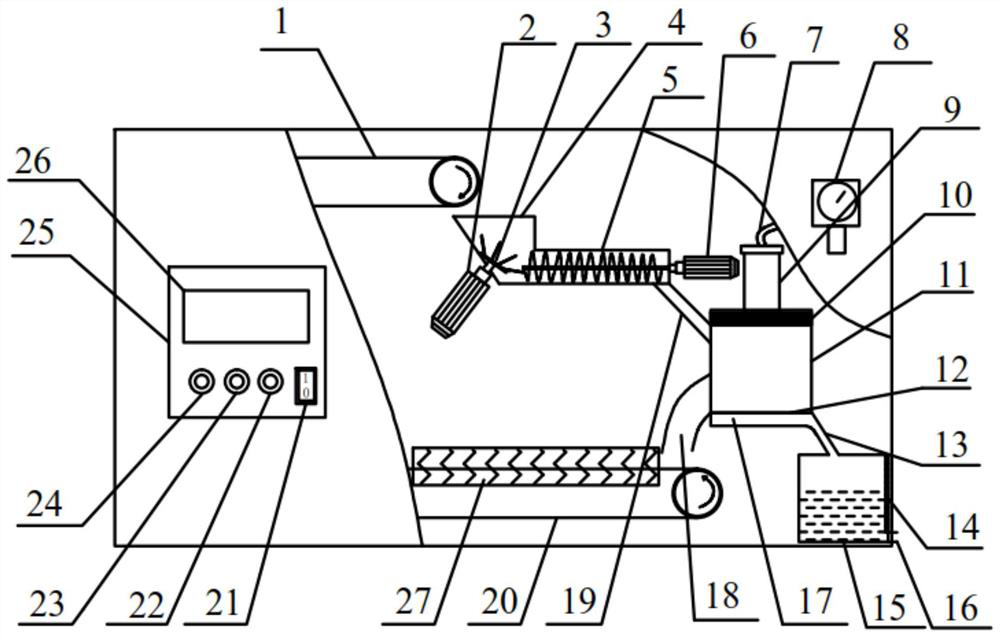

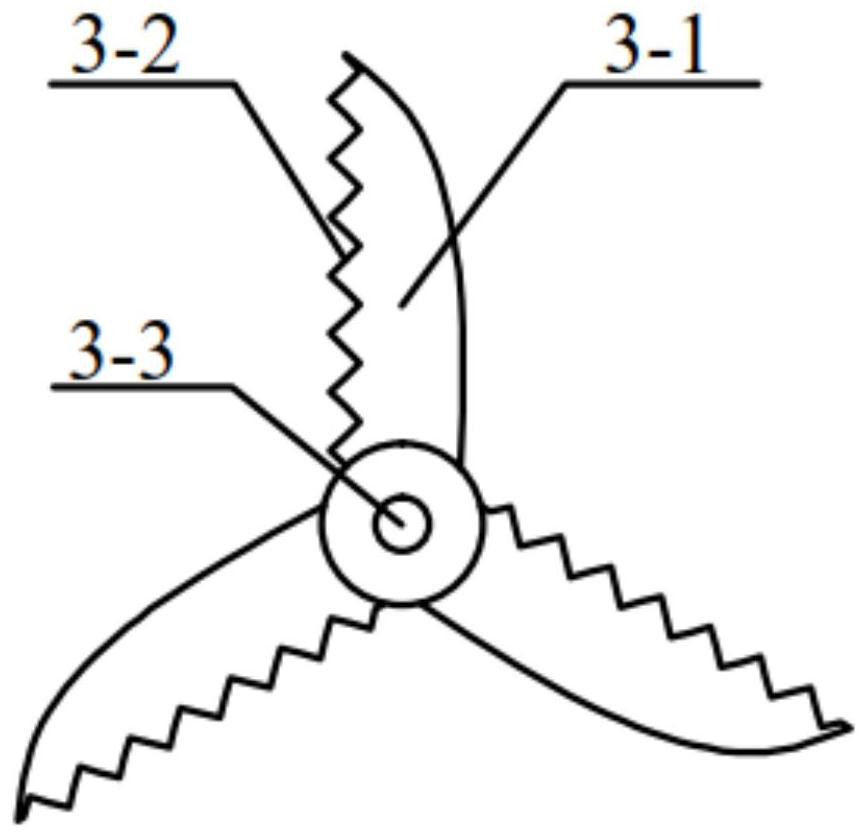

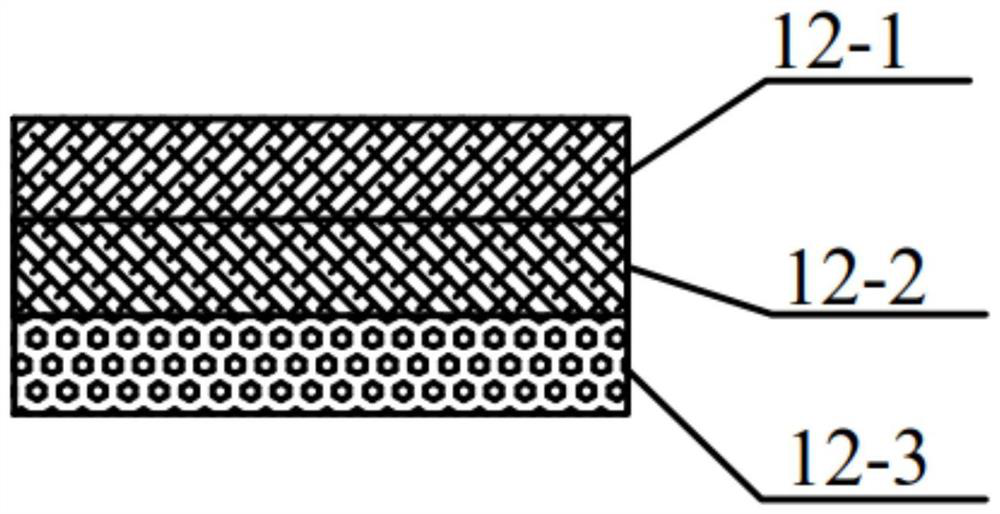

[0019] An automatic vegetable dehydration device, comprising a first conveyor belt 1, a first motor 2, a cutter 3, a material inlet 4, a screw propeller 5, a second motor 6, a pneumatic filter system, a liquid level sensor 14, and a liquid storage chamber 15. Liquid outlet 16, filtrate chamber 17, discharge pipe 18, first connecting pipe 19, second conveyor belt 20, PLC control system, operation interface 25 and drying device 27; the cutter 3 includes a blade 3-1 , knife tooth 3-2 and rotating shaft 3-3, described pneumatic filter press system comprises air delivery pipe 7, pressure gauge 8, cylinder 9, briquetting block 10, press filter chamber 11, filter plate 12 and second connecting pipe 13, so The filter plate 12 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com