An explosion-proof safety grinding device

A grinding device, safe technology, used in grain processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

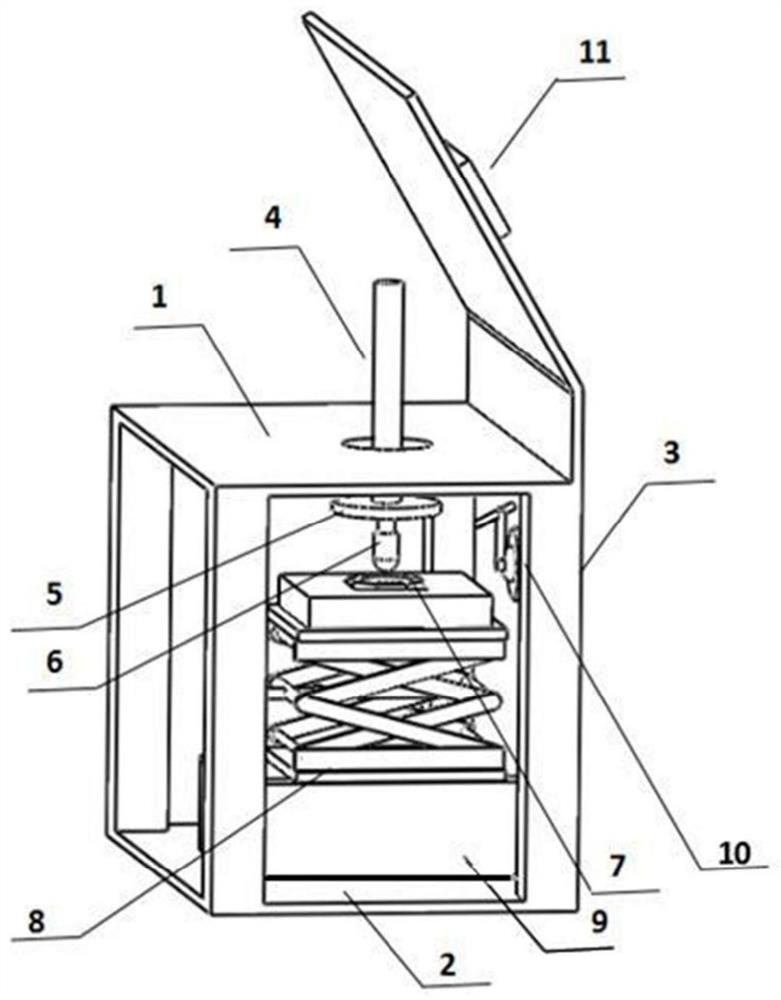

[0014] See this example figure 1 As shown, during the grinding operation, the operator weighs a 5g TNT equivalent sample, places the sample in the mortar 7, and fixes it in the upper frame of the lifting platform 8, wherein the lifting platform is an aluminum-magnesium alloy lifting platform of 20cm*20cm , by adjusting the aluminum-magnesium alloy lifting platform 8 to make the mortar in the best grinding position, the grinding rod is made of a wooden grinding rod 4, a 5mm thick titanium alloy lower protective plate 5 and an agate grinding head 6 with a diameter of 110mm. The materials of horizontal protective plate 1, vertical protective plate 3 and protective bottom plate 2 are all 10mm thick carbon steel. The operator is located on one side of the vertical protective plate 3, passes through a circular opening with a diameter of 55mm at the horizontal protective plate 1, wears anti-scald gloves, holds the grinding rod 4 for grinding, and the inner side of the vertical protec...

Embodiment 2

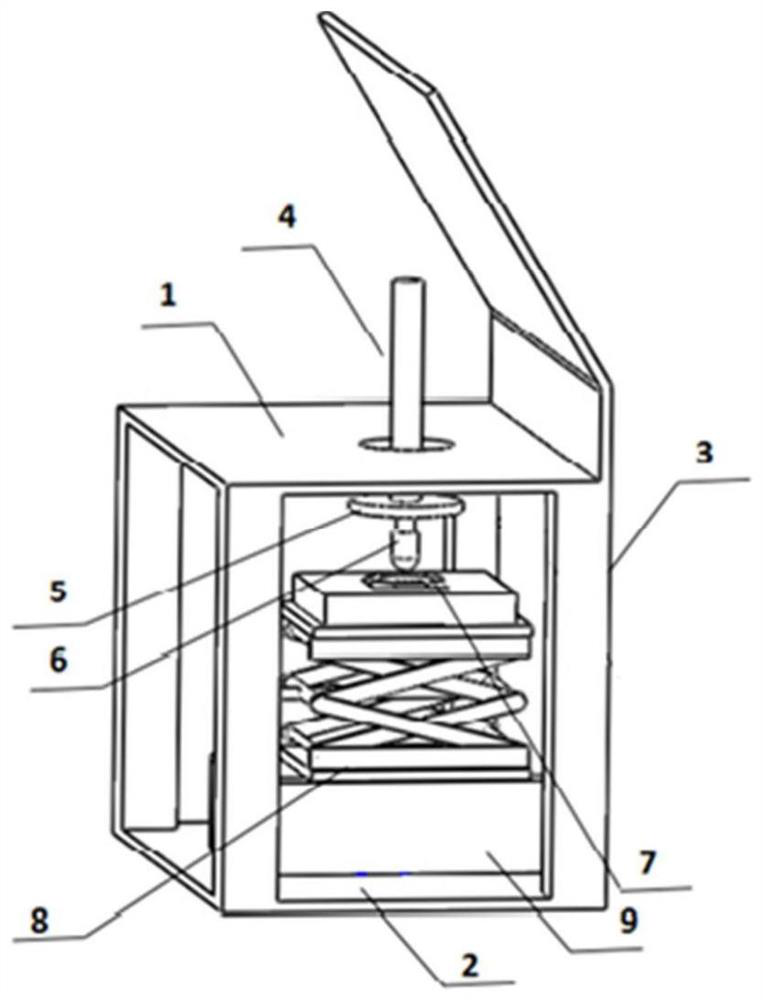

[0017] See this example figure 2 As shown, during the grinding operation, the operator weighs 5g of TNT equivalent sample, places it in the mortar 7, and fixes it in the upper frame of the aluminum-magnesium alloy lifting platform 8, wherein the lifting platform is a 20cm*20cm aluminum-magnesium alloy lifting platform. Platform, make the mortar be in the best grinding position by adjusting the lifting platform 8, the grinding rod is made of wooden grinding rod 4, 10mm thick diameter explosion-proof glass lower protective plate 5 and agate grinding head 6 of 110mm. Horizontal protective plate 1 and vertical protective plate 3 are made of transparent explosion-proof glass with a thickness of 10 mm. The operator is located on one side of vertical protective plate 3 and passes through the circular opening with a diameter of 55 mm in horizontal protective plate 1. Wear anti-scald gloves and hold The grinding rod 4 is ground, and the grinding process is observed through the explosi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap