Decontamination vehicle

A technology for decontaminating and cleaning vehicles, which is applied to decontaminating vehicles. It can solve the problems of reducing the decontamination efficiency of vehicles to be cleaned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further detailed explanation through specific implementation mode below:

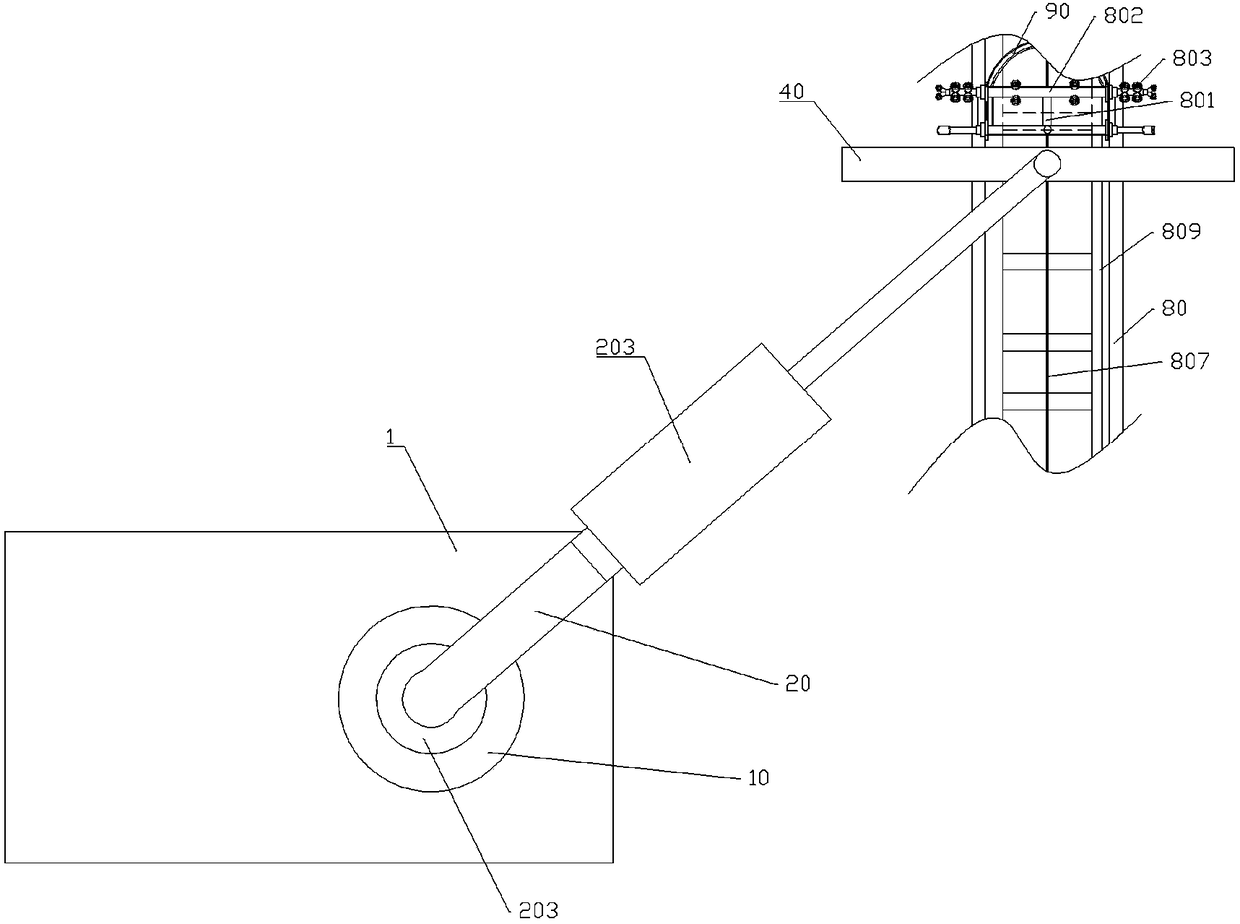

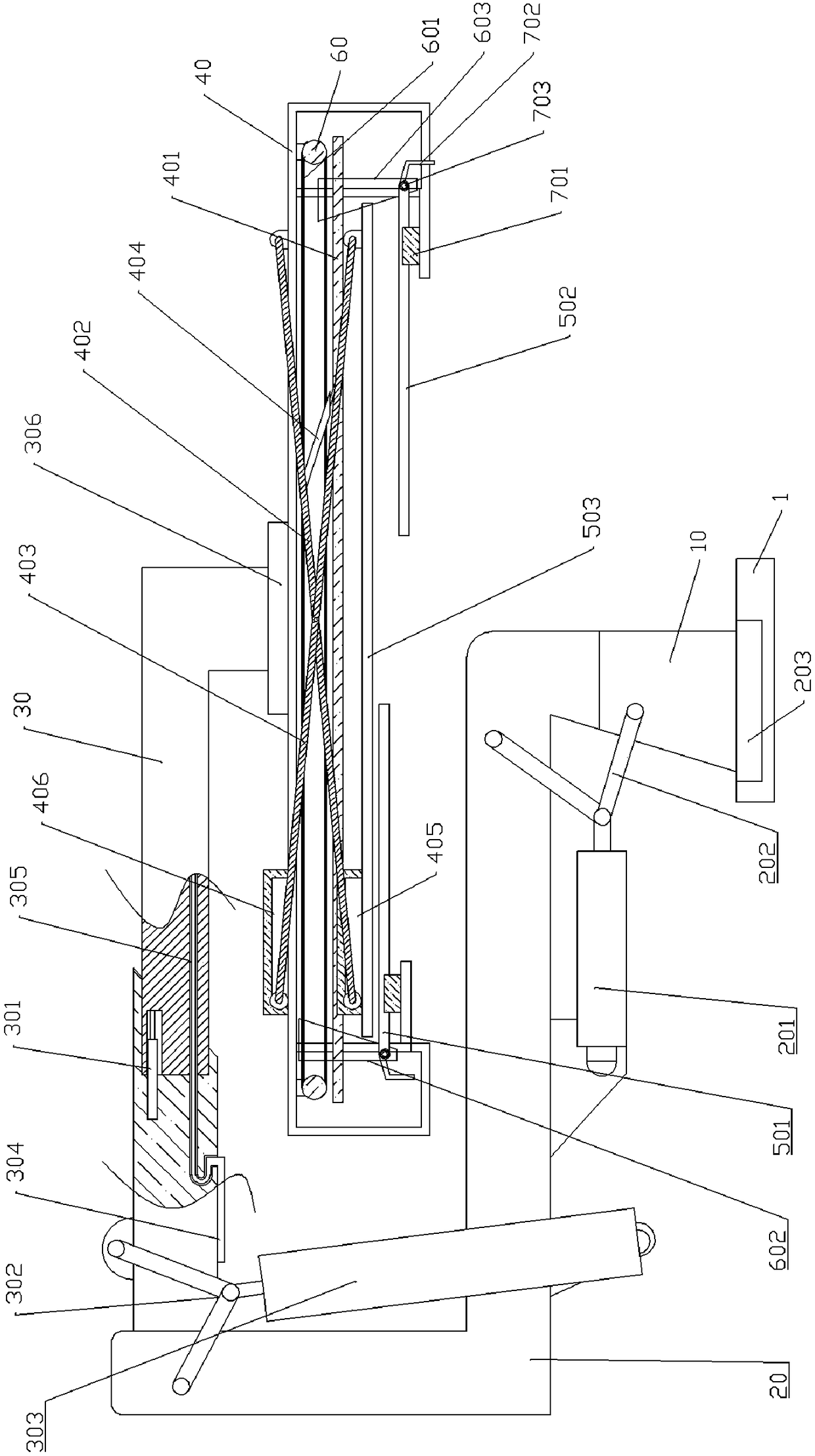

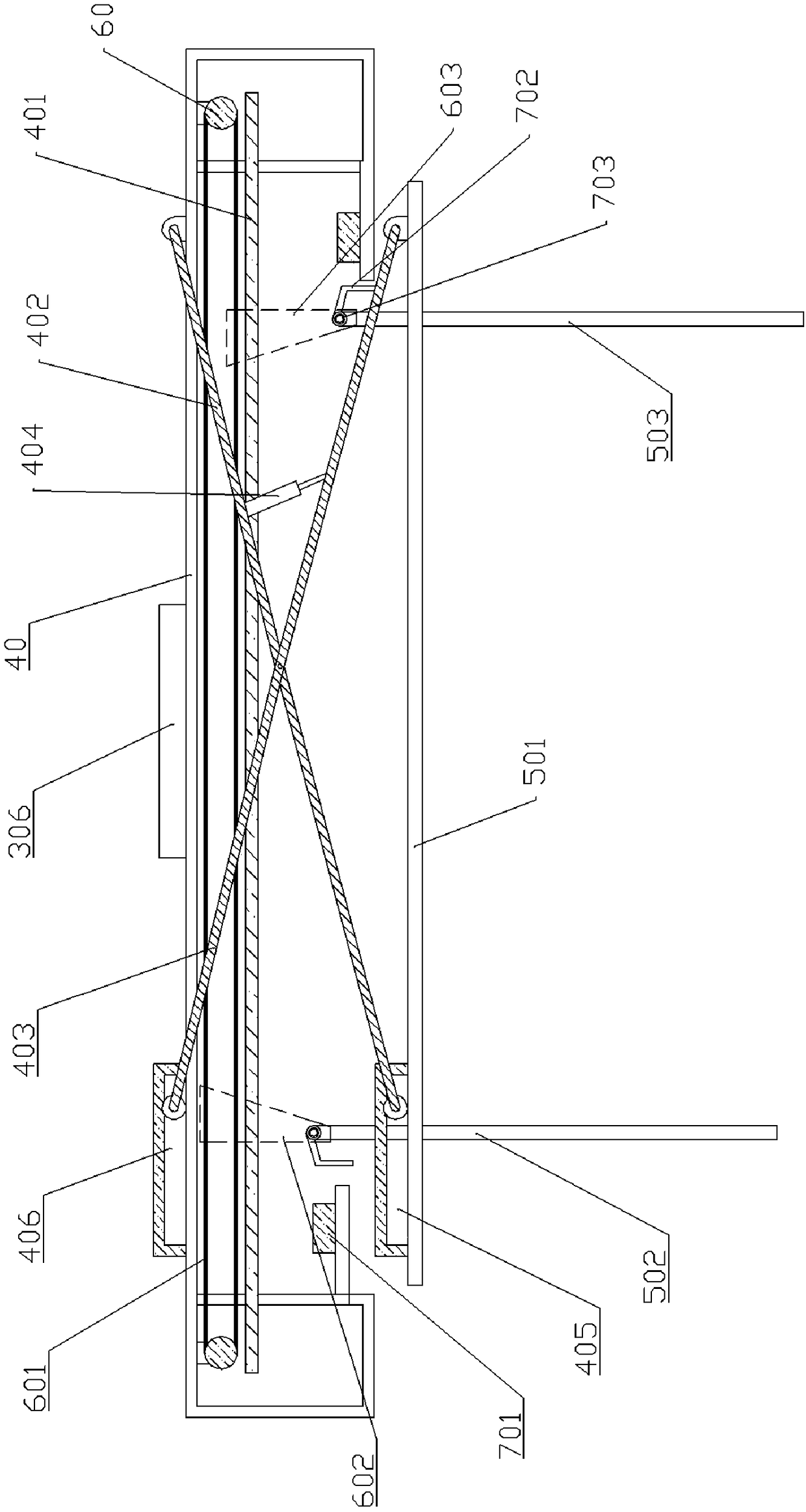

[0026] The reference signs in the accompanying drawings of the specification include: car body 1, support seat 10, lower arm layer 20, first oil cylinder 201, first hinged rod 202, first rotary motor 203, telescopic arm layer 30, telescopic oil cylinder 301, the first Two hinge rods 302, second oil cylinder 303, water inlet pipe 304, first drag chain 305, second rotary motor 306, installation frame layer 40, slide rail 401, first connecting rod 402, second connecting rod 403, lifting cylinder 404 , the first chute 405, the second chute 406, the first cleaning rod 501, the second cleaning rod 502, the third cleaning rod 503, the sprocket 60, the first chain 601, the first mounting block 602, the second mounting block 603, limit block 701, gas strut 702, spring 703, guide rail 80, cleaning vehicle 801, spray bar 802, nozzle 803, motor 804, second chain 805, driving wheel 806, traction rope 807, dri...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap