Preparation method of IS90 insoluble sulfur and antistatic agent for preparing IS90 insoluble sulfur

An antistatic agent and sulfur technology, applied in the field of antistatic agents, can solve the problems of poor dispersibility of insoluble sulfur, and achieve the effects of ensuring thermal stability, ensuring mixing uniformity, and preventing the impact of product performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

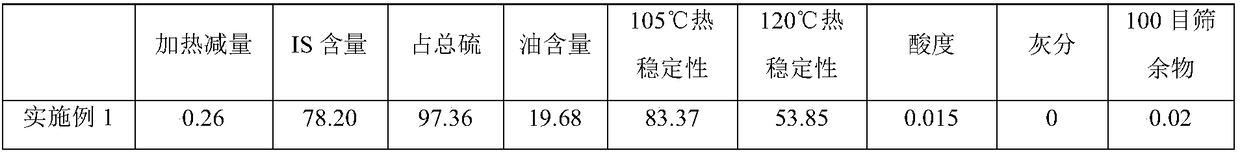

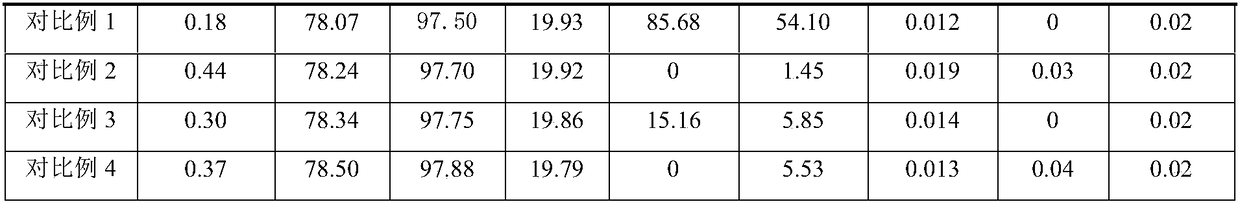

Embodiment 1

[0028] A kind of preparation method of IS90 insoluble sulfur of the present embodiment, use liquid sulfur as raw material, adopt gasification-quick cooling method to produce and obtain IS60 semi-finished product, carry out extraction, drying and sieving successively on IS60 semi-finished product to obtain IS90 semi-finished product, then obtain The IS90 semi-finished product is uniformly mixed with rubber oil and antistatic agent to obtain IS90 insoluble sulfur finished product. The antistatic agent is composed of fatty alcohol polyoxyethylene ether and polybutylene, and the mass percentage of fatty alcohol polyoxyethylene ether and polybutylene is 10% and 90% respectively, and the addition amount of the antistatic agent is 3% of the mass of the obtained IS90 insoluble sulfur finished product.

[0029] The dispersibility of insoluble sulfur products is crucial to its application effect. Sulfur with poor dispersibility will generate static electricity, which will cause all the s...

Embodiment 2

[0031] The preparation method of a kind of IS90 insoluble sulfur of this embodiment, its step is basically the same as embodiment 1, and its difference mainly lies in: the extraction solution of this embodiment adopts CS 2 , put the extracted product in a drying pot, heat it with hot water to increase the temperature of the product from 15°C to 60°C, and then use a 100-150 mesh screen for sieving treatment to obtain an IS90 semi-finished product. The obtained IS90 semi-finished product is mixed evenly with rubber oil and antistatic agent to obtain IS90 insoluble sulfur finished product. The mass percentages of fatty alcohol polyoxyethylene ether and polybutylene in the antistatic agent of the present embodiment are respectively 12%, 88%, And the addition amount of antistatic agent is 3.4% of the mass of the obtained IS90 insoluble sulfur finished product.

Embodiment 3

[0033]A kind of preparation method of IS90 insoluble sulfur of the present embodiment, its preparation process is basically the same as embodiment 2, and its difference mainly is: the mass percent of fatty alcohol polyoxyethylene ether and polybutylene in the antistatic agent of present embodiment is respectively 11%, 89%, and the amount of antistatic agent added is 4.5% of the mass of the obtained IS90 insoluble sulfur product. At the same time, when mixing the IS90 semi-finished product with rubber oil, a certain amount of iodine is added, and the amount of iodine added is the obtained IS90 insoluble sulfur 1‰ of finished product quality. In this embodiment, a certain amount of iodine is added during the oil-filling treatment, and the amount of iodine added is optimized, so as to effectively ensure the thermal stability of the obtained product and further prevent the impact of the addition of antistatic agents on the thermal stability of sulfur , At the same time, it can als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com