Combined brake disc and braking device

A brake disc, combined technology, applied in the direction of brake disc, brake type, brake parts, etc., can solve the problem of disengagement, affecting the braking effect and service life of the brake disc, and the loose position of the friction disc and the brake disc base and other problems to achieve the effect of increasing the force bearing area, improving the braking effect and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

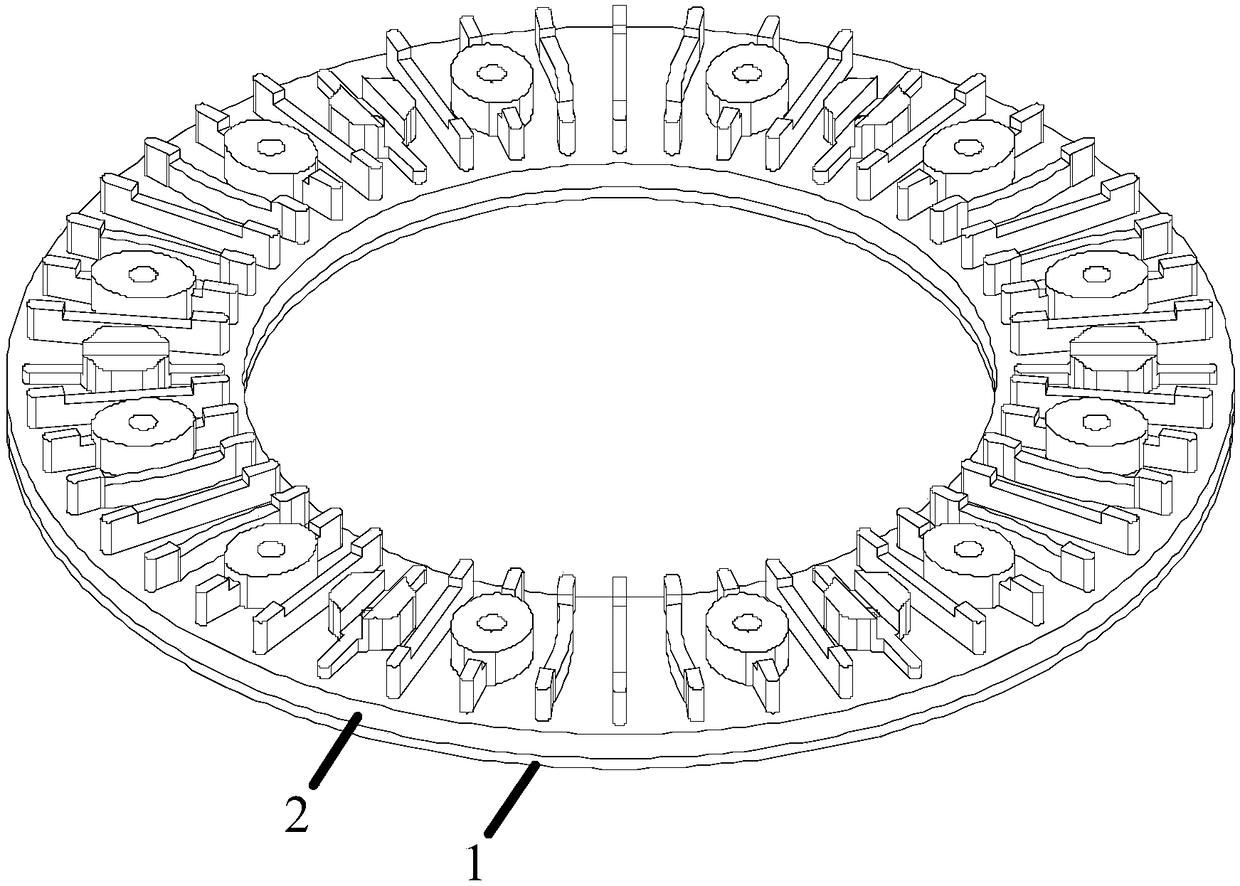

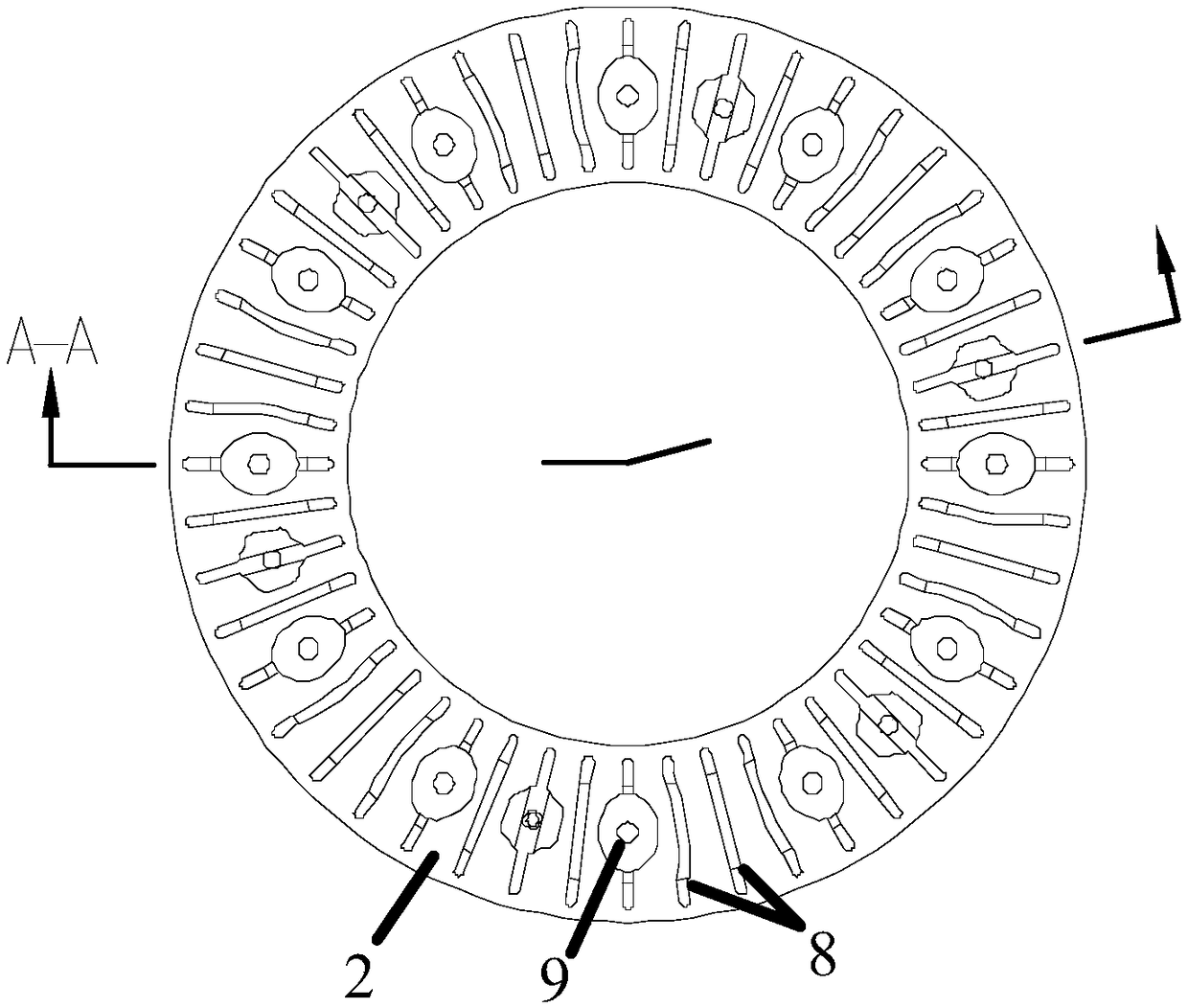

[0043] A brake device is described, which includes a combined brake disc with a wheel disc structure and a brake pad matched with the combined brake disc. Such as Figure 1 to Figure 4 The combined brake disc shown includes:

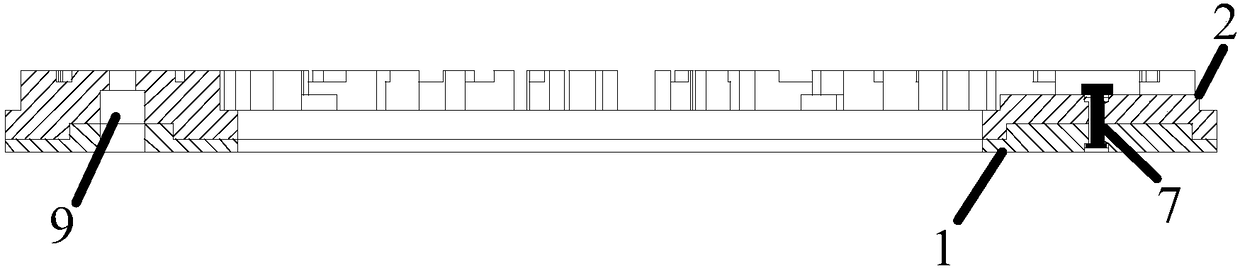

[0044] Such as Image 6 The brake disc base body 2 shown is an annular disc body. The upper surface of the brake disc base body 2 is provided with heat dissipation ribs, and the lower surface has an annular groove 4 arranged along the circumferential direction of the combined brake disc. The inner ring side wall of the annular groove 4 is arranged along the inner ring contour edge of the combined brake disc, and the outer ring side wall of the annular groove 4 is along the outer ring contour edge of the combined brake disc Set up

[0045] Such as Figure 5 The friction disc 1 shown is mounted on the lower surface of the brake disc base body 2. The upper surface of the friction disc 1 is provided with an annular boss 3 that is adapted to the annular groove 4...

Embodiment 2

[0050] The difference between this embodiment and the first embodiment is that the brake disc base 2 is an annular disc body, the upper surface of the brake disc base 2 is provided with heat dissipation ribs, and the lower surface has a circumferential direction of the combined brake disc. The ring boss 3;

[0051] The friction disc 1 is installed on the lower surface of the brake disc base body 2. The upper surface of the friction disc 1 is provided with an annular groove 4 that is adapted to the annular boss 3, and the annular groove 4 The inner ring side wall is arranged along the inner ring contour edge of the combined brake disc, and the outer ring side wall of the annular groove 4 is arranged along the outer ring contour edge of the combined brake disc; The groove 4 and the annular boss 3 are mated and clamped to prevent the friction disc from sliding in a relatively parallel position on the connecting surface with respect to the brake disc base body under the combined acti...

Embodiment 3

[0053] The difference between this embodiment and the first embodiment is that the protruding portion 5 and the inner concave portion 6 are concave-convex structures arranged on the connecting surface of the annular groove 4 and the annular boss 3. The protruding part 5 and the inner concave part 6 are strip-shaped structures arranged along the radial direction of the brake disc to prevent relative rotation of the friction disc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com