LED filament structure and LED lighting lamp based on LED filament structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

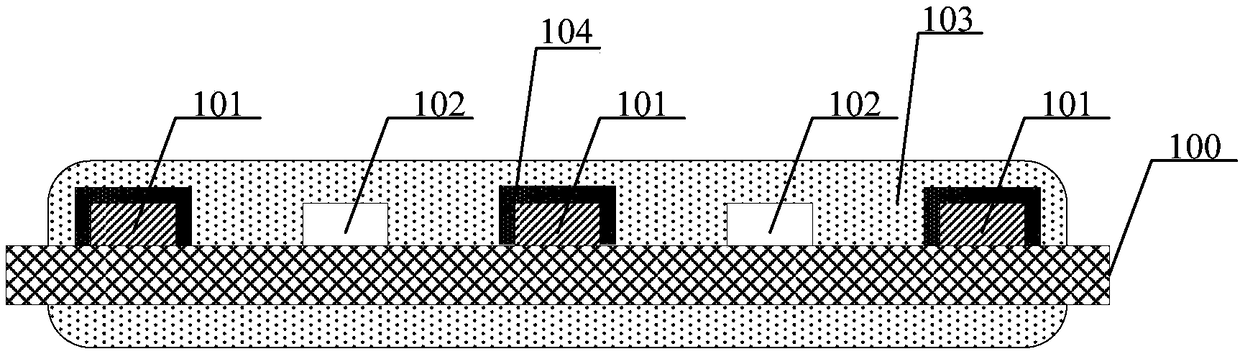

[0051] Such as Figure 1~2 And as shown in 4~5, the present invention provides a kind of LED filament structure, and described LED filament structure comprises:

[0052] Substrate 100;

[0053] The LED chip assembly is arranged on the substrate 100, the LED chip assembly includes at least one first LED chip 101 and at least one second LED chip 102, and there is a distance between adjacent LED chips;

[0054] A fluorescent material layer 103 is disposed on the substrate 100, and the fluorescent material layer 103 covers each of the LED chips;

[0055] The filter material layer 104 covers the surface of at least one of the first LED chip 101 and the second LED chip 102. When the LED filament structure is just lit, the filter material layer 104 has an absorption state, so that one of the first LED chip 101 and the second LED chip 102 excites the fluorescent material layer 103 to emit light of a first color temperature, and after the LED filament structure lights up for a preset...

Embodiment 2

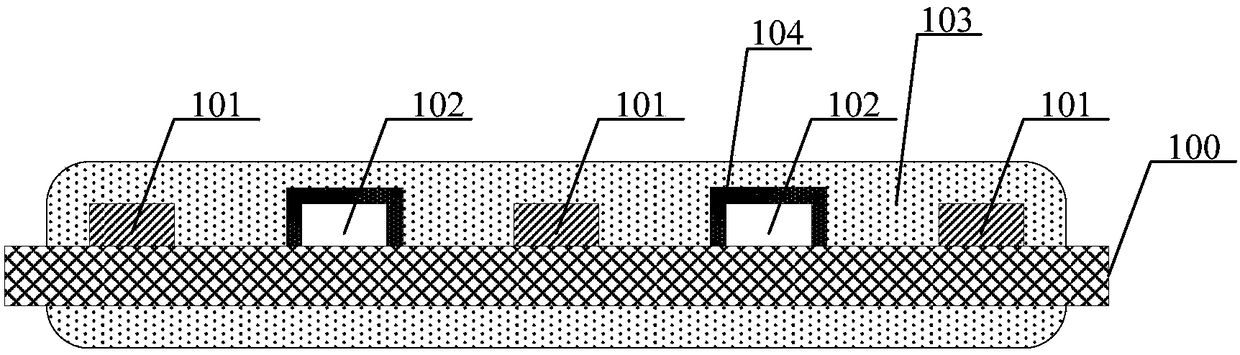

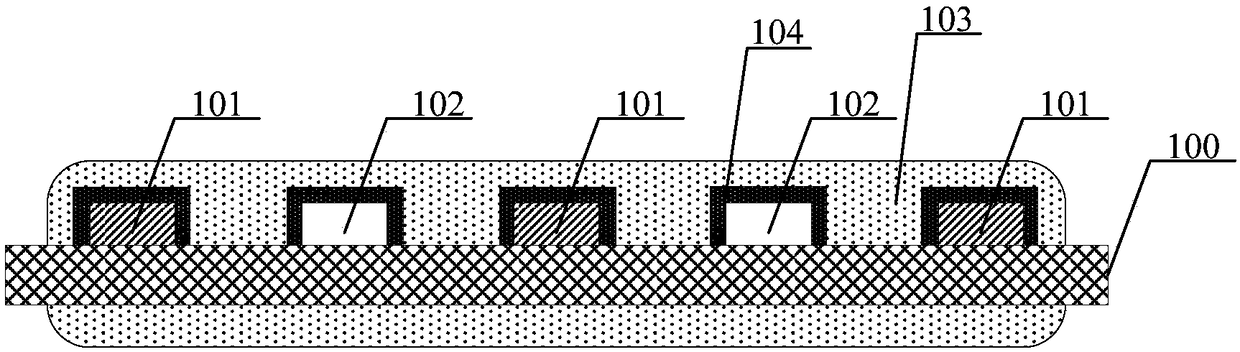

[0084] Such as Figure 3-5 As shown, the present invention provides a kind of LED filament structure, and described LED filament structure comprises:

[0085] Substrate 100;

[0086] The LED chip assembly is arranged on the substrate 100, the LED chip assembly includes at least one first LED chip 101 and at least one second LED chip 102, and there is a distance between adjacent LED chips;

[0087] A fluorescent material layer 103 is disposed on the substrate 100, and the fluorescent material layer 103 covers each of the LED chips;

[0088]The filter material layer 104 covers the surface of at least one of the first LED chip 101 and the second LED chip 102. When the LED filament structure is just lit, the filter material layer 104 has an absorption state, so that one of the first LED chip 101 and the second LED chip 102 excites the fluorescent material layer 103 to emit light of a first color temperature, and after the LED filament structure lights up for a preset time, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com