Electrode connecting device for pulse xenon lamp

A connecting device and pulsed xenon lamp technology, applied in the field of electric light source, can solve the problems that the electrodes are easily polluted by solder, reduce the reliability of high-voltage insulation of xenon lamps, and the electric field strength is abnormally high, and achieve simple and stable assembly process, and the connection area and cross-section The effect of large area and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

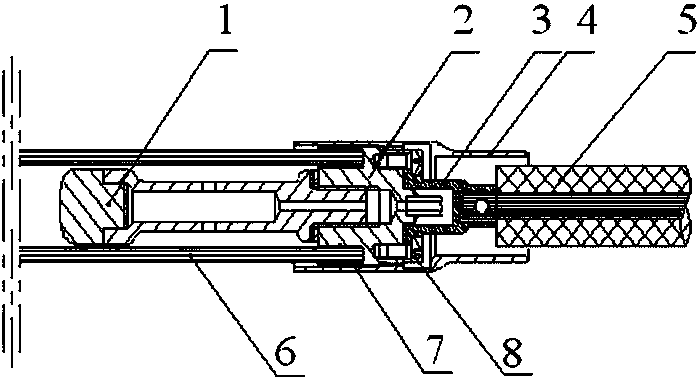

[0040] The installation process of the pulse xenon lamp electrode connection device of this embodiment is as follows:

[0041] a. Use a torque wrench to connect the electrode to the electrode cap through threads, and the torque setting value is 17N·m~19N·m;

[0042] b. Cut the solder into solder pieces with a width of about 10mm to 15mm, and wrap them on the outer surface of the tail end of the quartz tube, and then insert the tail end of the quartz tube wrapped with the solder pieces into the annular groove of the electrode cap equipped with electrodes;

[0043] c. Put the quartz tube equipped with electrodes, electrode caps and solder vertically into a vacuum brazing furnace at a temperature not higher than 5×10 -3 Heating to above 600°C in a vacuum environment of Pa until the solder melts and fully reacts with the quartz glass, and the quartz tube and the electrode cap are directly welded into a whole;

[0044] d. After filling the quartz tube with a certain amount of xeno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com