In-well magnetic chipping fisher

An overshot and magnetic technology, applied in wellbore/well parts, earthwork drilling and mining, etc., can solve problems such as low construction efficiency and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

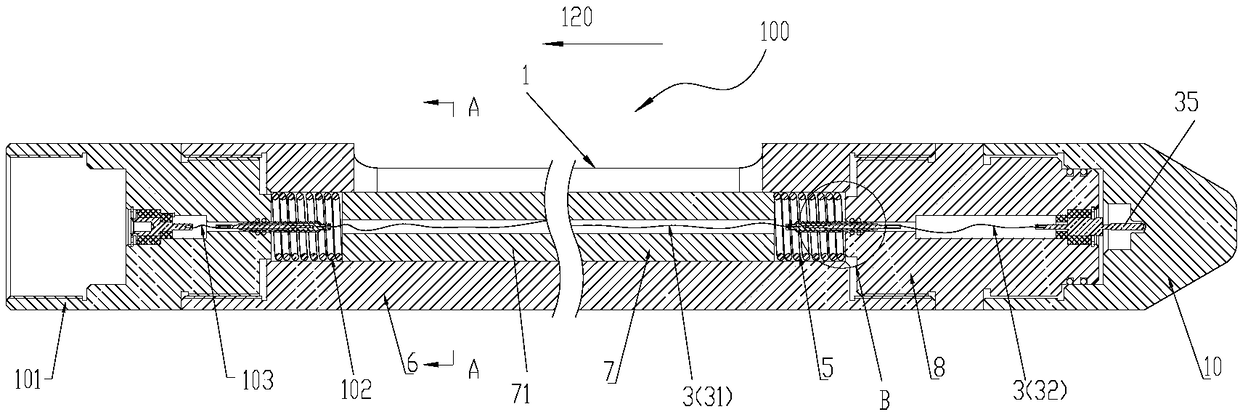

[0022] In this application document, the direction term "upstream" is as figure 1 As indicated by arrow 120 in , "downstream" is the direction opposite to "upstream".

[0023] figure 1 The structure of the well debris magnetic overshot 100 (hereinafter referred to as the overshot 100 for short) according to the present invention is schematically shown. Such as figure 1 As shown, the overshot 100 includes a fishing main body 1 , an electric control tool 10 connected to the downstream end of the fishing main body 1 , and a cable 3 . The salvage main body 1 has magnetism to absorb metal debris in the well and complete the salvage operation. The cable 3 axially passes through the fishing body 1 and is connected to the electric control tool 10 to supply power and / or transmit signals to the electric control tool 10 . In this way, when the overshot 100 is used to carry out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com