Oil collecting box of integrated stove and manufacturing method thereof

A technology integrating stoves and oil collection boxes, applied in applications, household stoves, household heating, etc., can solve the problems of shortening the service life of oil quantity reminder devices, metal parts being easily contacted with water, and oil collection boxes being inconvenient to clean, etc. Circuit control device, increased strength, simple steps effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

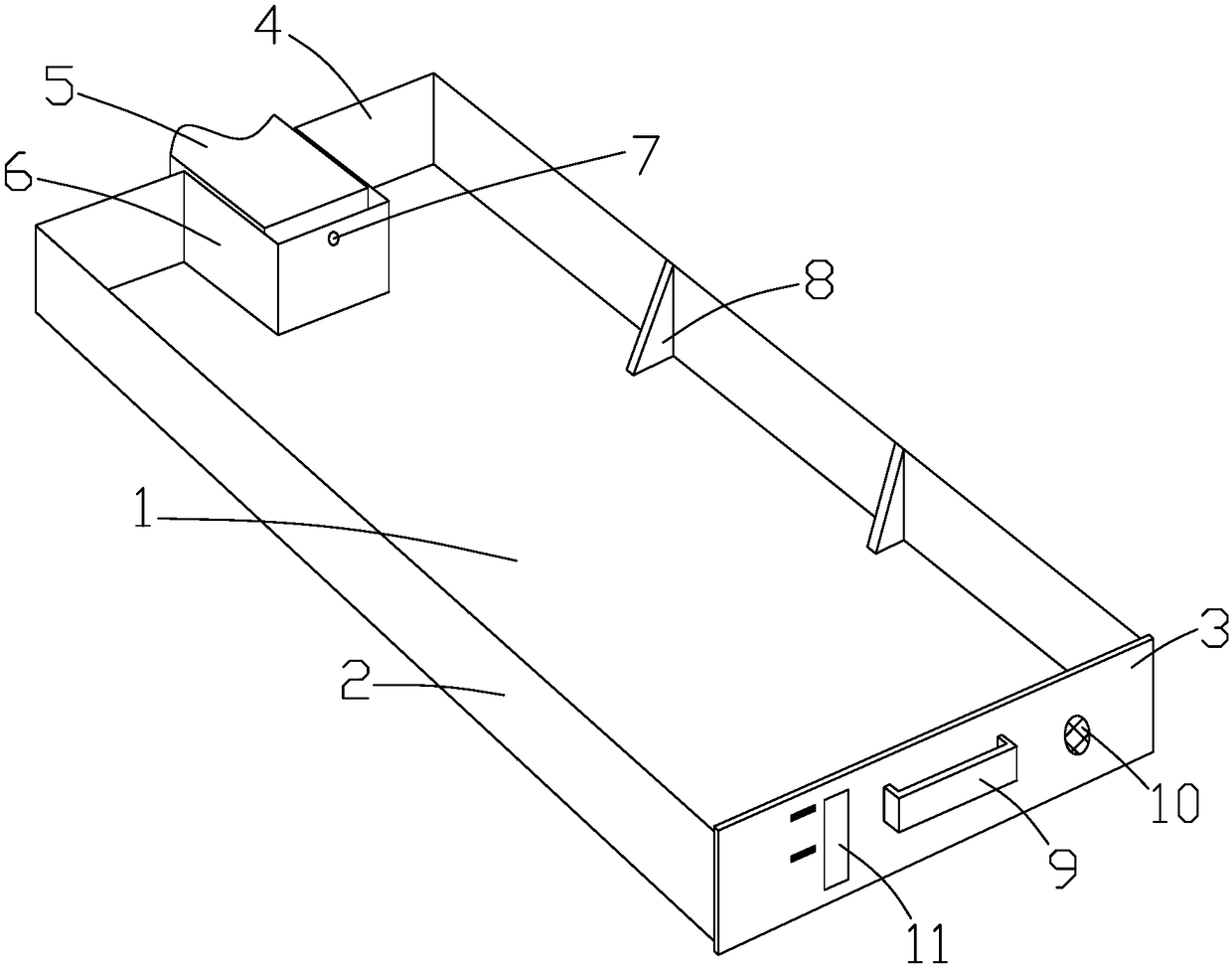

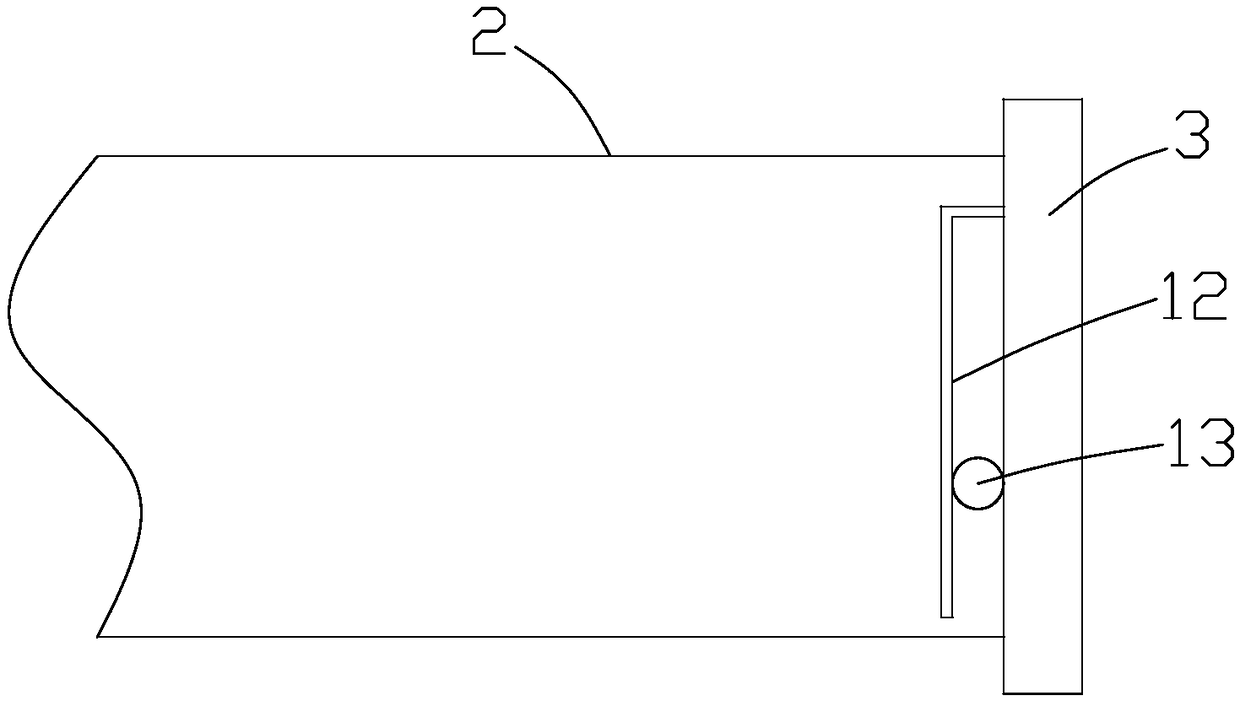

[0043] Such as Figure 1 to Figure 6As shown, it is an oil collection box for an integrated stove according to the present invention, which includes a bottom plate 1, a front plate 3, a rear plate 4 and side plates 2, and the front plate 3, the rear plate 4 and two side plates 2 are all located on the top of the bottom plate 1 On the surface, and the end to end connection forms a closed structure, and a reinforcing rib 8 is arranged between the side plate 2 and the bottom plate 1. The design of the reinforcing rib 8 greatly improves the strength of the oil collecting box and prolongs the service life of the oil collecting box.

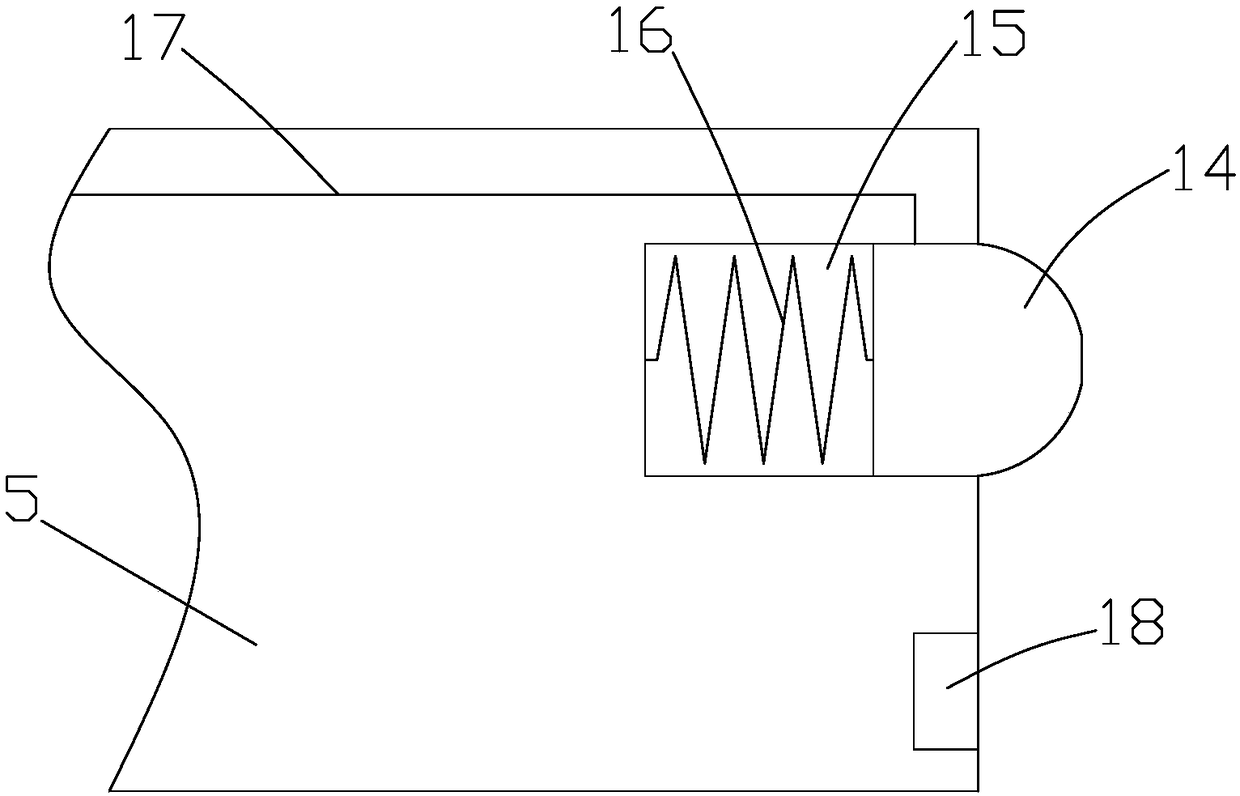

[0044] Handrail 9 is arranged on the outer surface of front plate 3, and observation window 11 and buzzer 10 are arranged on the outer surface of front plate 3, and observation window 11 and buzzer 10 are positioned at the both sides of handrail 9, and the inside of front plate 3 Hollow frame 12 is arranged on the side, and floating ball 13 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com