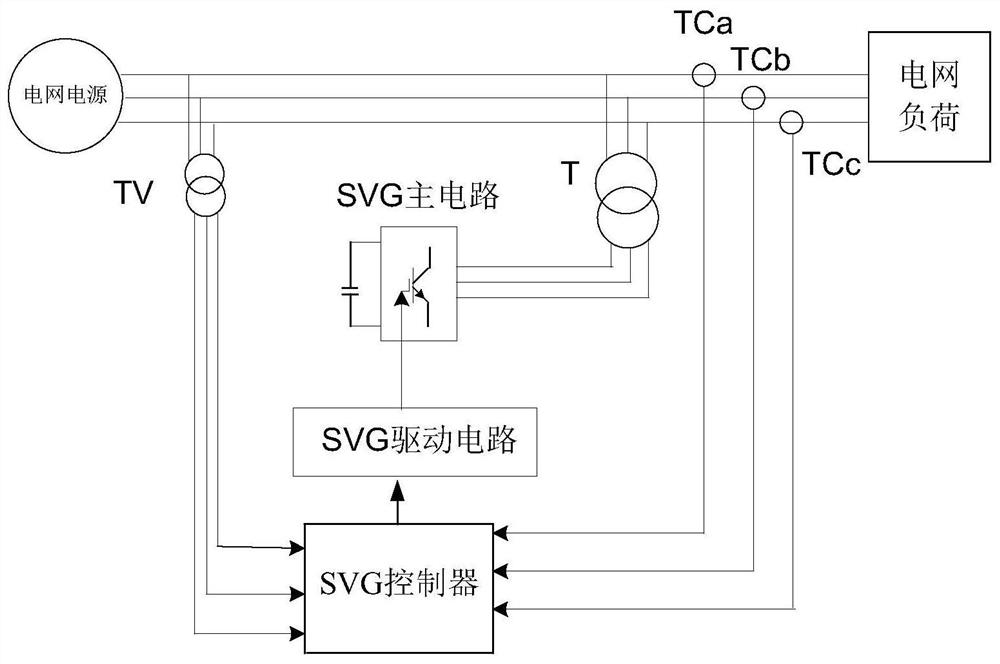

A voltage equalization switching control method for capacitors in a voltage-type high-voltage reactive power generator

A generator and voltage-type technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, electrical components, etc., can solve problems that are difficult to show the control effect of capacitor voltage equalization, uncontrollable components, control technology and hardware Design difficulties and other issues, to achieve the effect of reducing the number of sub-module units, good combination, improving reliability and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0040] It should be noted that all expressions using "first" and "second" in the embodiments of the present invention are to distinguish two entities with the same name but different parameters or parameters that are not the same, see "first" and "second" It is only for the convenience of expression, and should not be construed as a limitation on the embodiments of the present invention, which will not be described one by one in the subsequent embodiments.

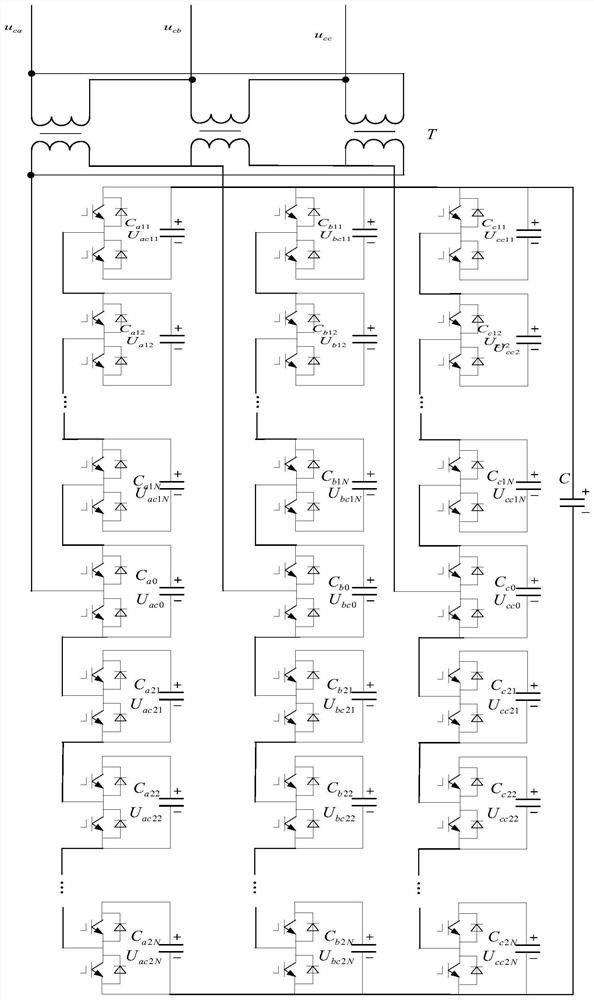

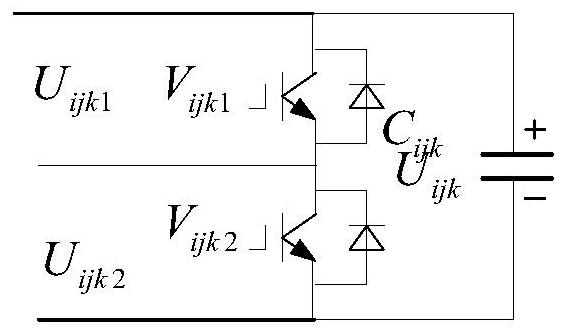

[0041] The purpose of this application is to provide an efficient method that can more fully, truly, whole-process, and finely reflect the behavior characteristics of capacitors in the working process of modular high-voltage reactive power generators, and overcome the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com