Unmanned automatic feeding ship adopting variable-amplitude sectional operation

An automatic bait feeding and automatic technology, which is applied in fishing boats, animal husbandry, fish farming, etc., can solve the problems of increasing the initial investment and operating costs of the system, so as to reduce manufacturing and operating costs, reduce the power of the matching machine, and reduce the hull effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

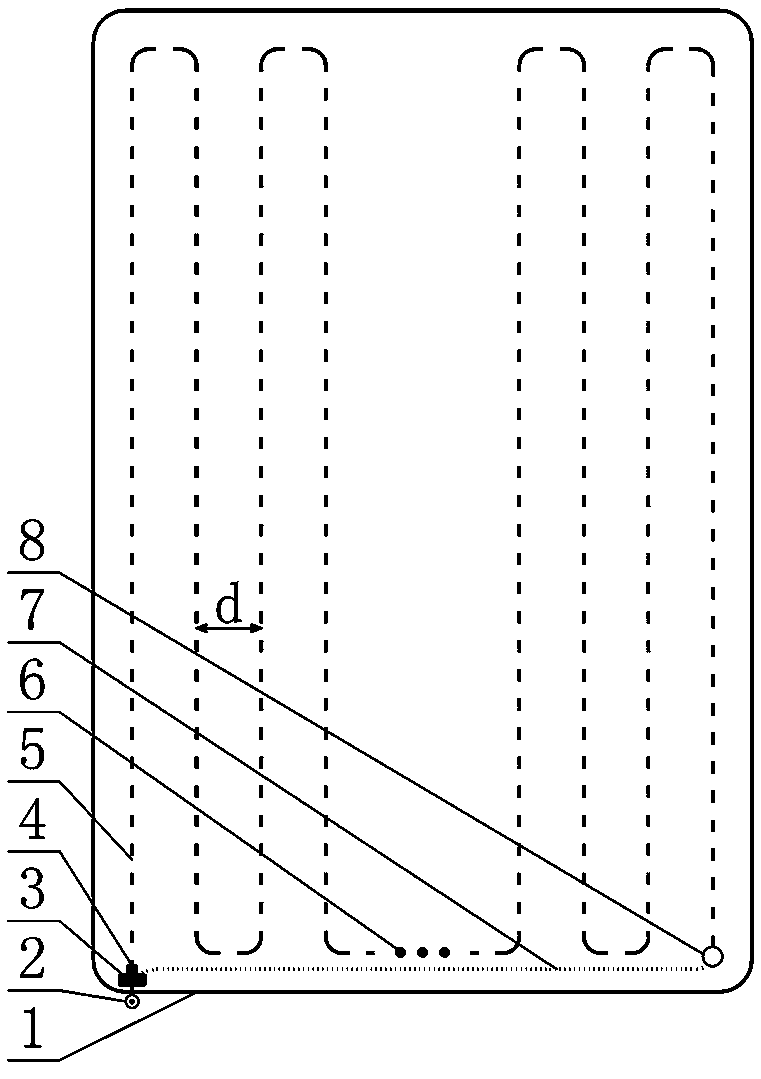

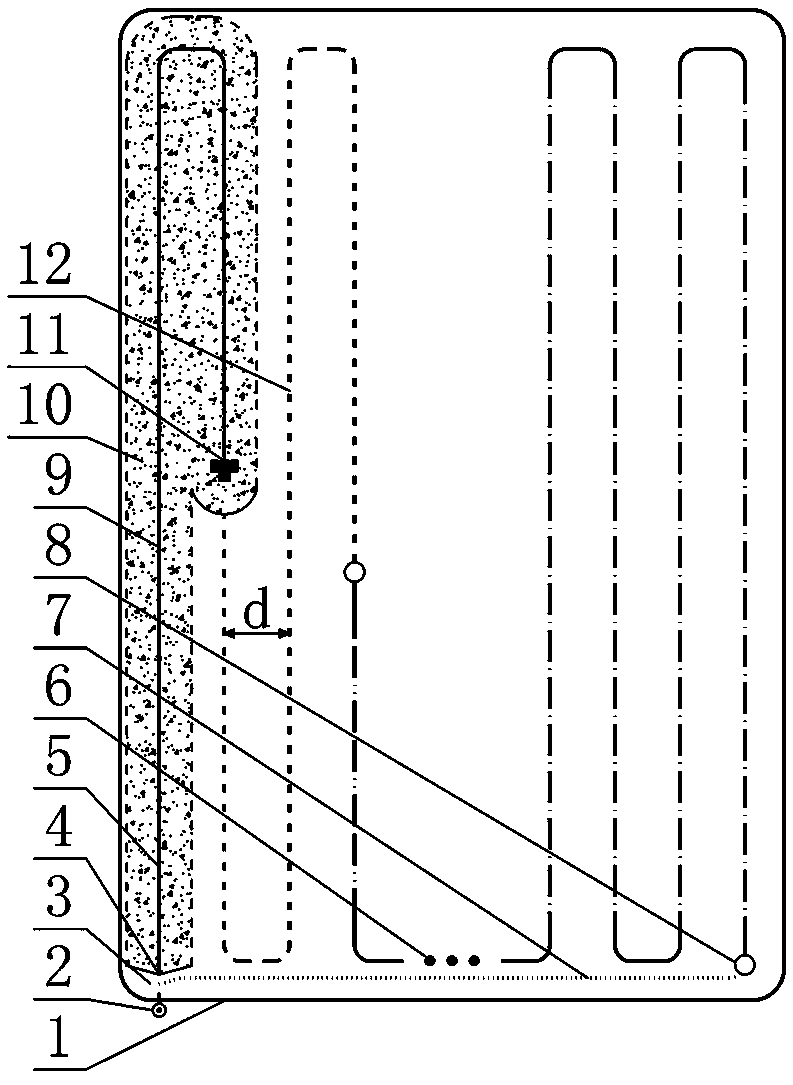

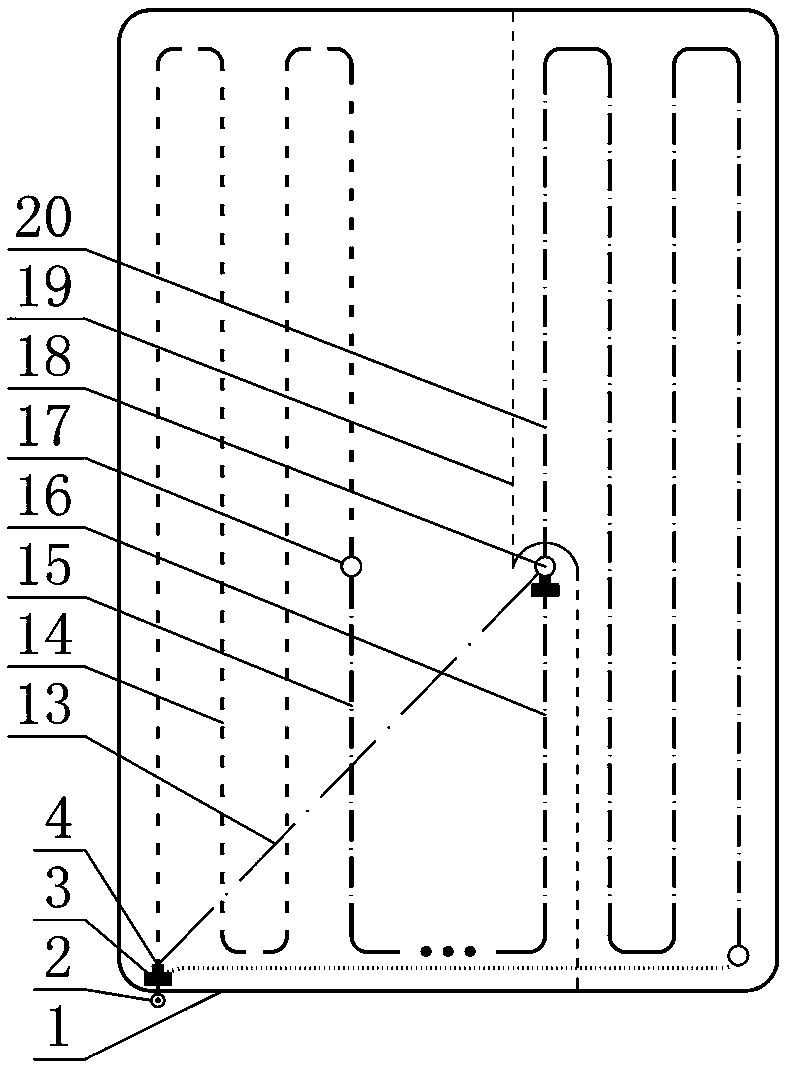

[0029] see figure 1 , the present embodiment provides an unmanned automatic bait-casting boat with variable amplitude and segmental operation, including an automatic feed bin 2 and an unmanned automatic bait-casting boat 3 .

[0030] Such as figure 1 As shown, when an unmanned automatic bait-throwing ship of the present invention operates in sections with variable amplitude, it realizes channel planning variable amplitude according to the following method:

[0031] (1) The main control unit of the unmanned automatic bait-casting ship 3 calls the GIS location of the operation area figure 1 , and confirm that the current location is included in the GIS location of the operation area figure 1 Inside, read the feeding control mode. There are three feeding control modes. The first mode is the density mode, that is, select the density mode and set the plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com