Photoresist spraying system

A photoresist and photoresist bottle technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of increasing human resource consumption, affecting film thickness, environmental pollution, etc., to reduce experimental uncertainties and reduce spray volume. Errors, the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed descriptions are given in conjunction with specific embodiments and accompanying drawings.

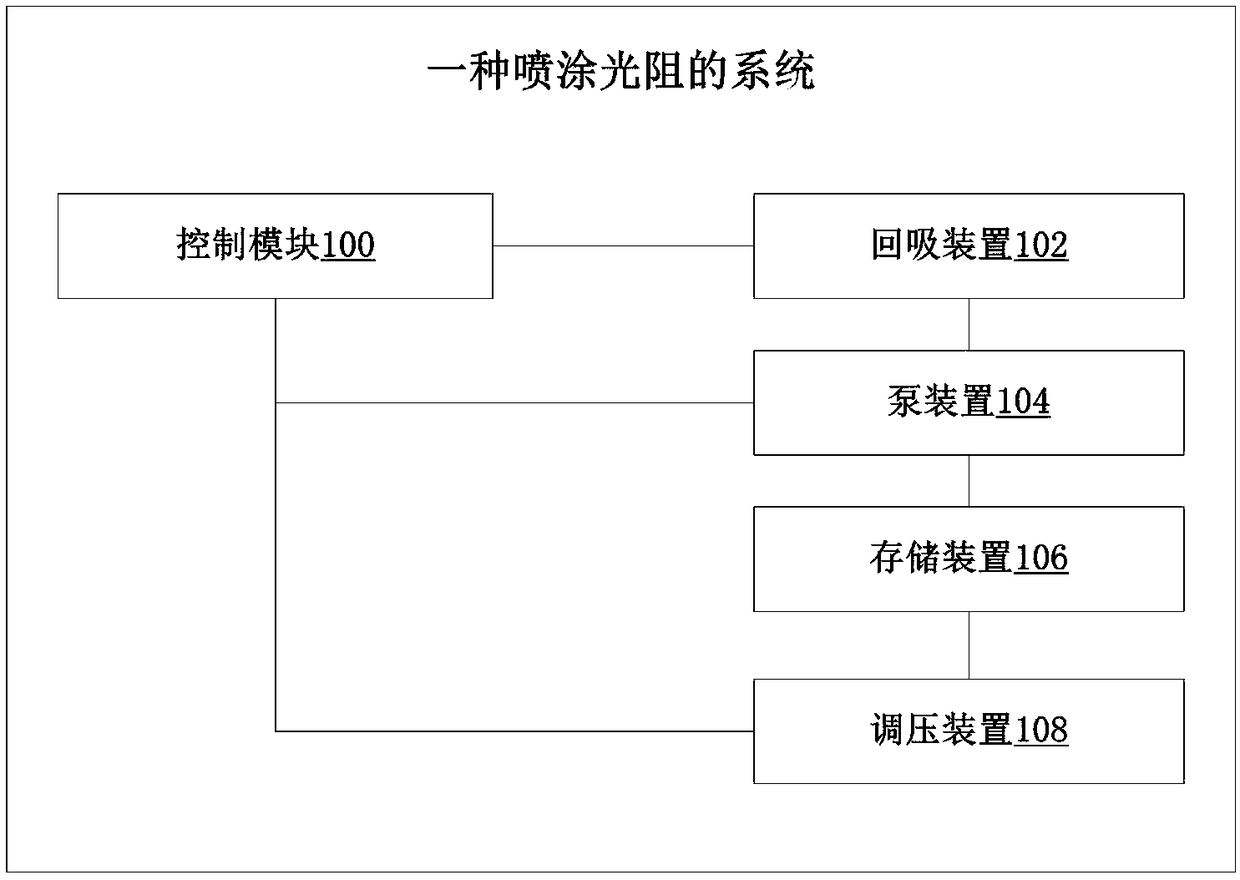

[0030] See figure 1 In this embodiment, a system for spraying photoresist is introduced, including a control module 100, a suction device 102, a pump device 104, a storage device 106, and a pressure regulating device 108;

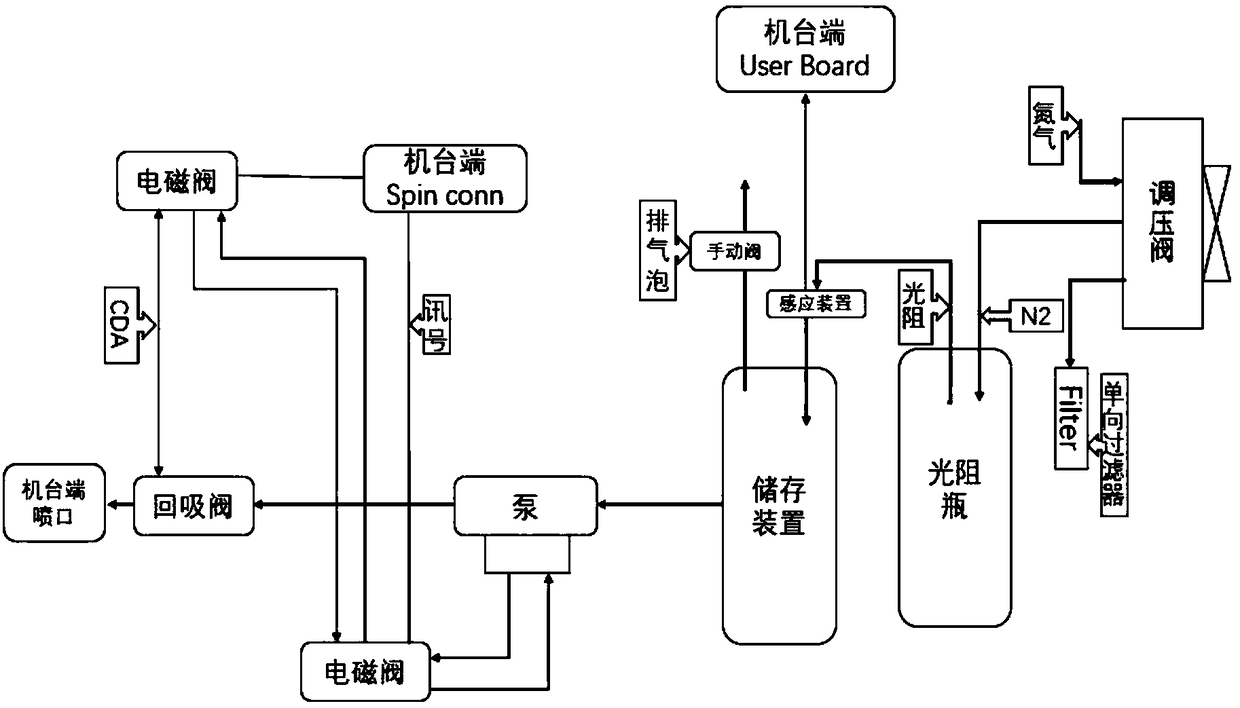

[0031] Please refer below figure 2 The control module is connected with the suction device, the pump device, the storage device, and the pressure regulating device, the suction device is connected with the spray nozzle, the pump device is connected with the suction device, and the pump device is also connected with the storage device. The storage device is used to connect the discharge end of the photoresist bottle, and the pressure regulating device is used to connect the pressurization end of the photoresis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com