Sample holder for high-temperature oxidation corrosion test and preparation method thereof

A corrosion test and high-temperature oxidation technology, applied in weather resistance/light resistance/corrosion resistance, instruments, measuring devices, etc., can solve the problems of not being able to use for a long time, test sample contamination, and no sample holder, etc., to save costs and avoid Effects that influence each other and increase intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

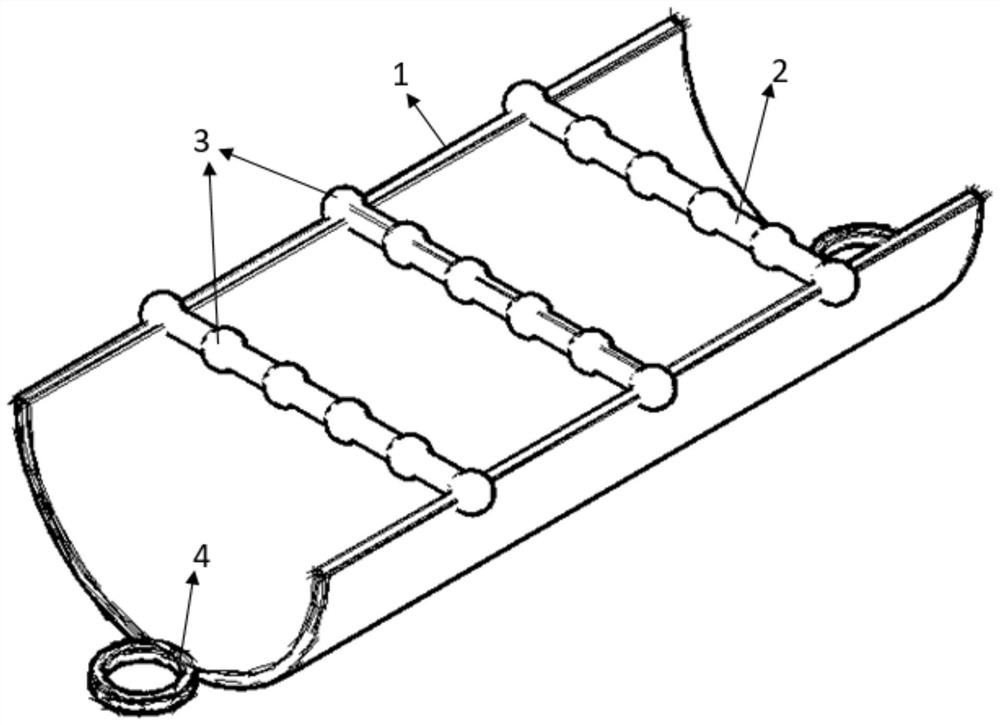

[0026] see figure 1 , a kind of sample holder for high temperature oxidation corrosion test provided by the present invention, comprises quartz boat body 1, hanging rod 2, anti-slip ring 3 and pull ring 4, wherein: the two ends of quartz boat body 1 are open, quartz boat body 1 The top is provided with a plurality of hanging rods 2 along the width direction for hanging the samples, and a plurality of anti-slip rings 3 are arranged on the hanging rods 2 along its length direction to prevent the samples from moving back and forth and avoid mutual influence between the samples. Quartz Two ends of the boat body 1 are respectively provided with a pull ring 4 .

[0027] Preferably, the body of the quartz boat is semi-cylindrical, with openings at both ends of the cylinder, and a wall thickness of 2-5 mm.

[0028] Preferably, the number of hanging r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com