Intermittent glue filling device for automatic glue filling of wire harness terminal

A wire harness terminal, intermittent technology, applied in the field of intermittent glue filling device, can solve the problems of large equipment volume and complex structure of glue dispensing device, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

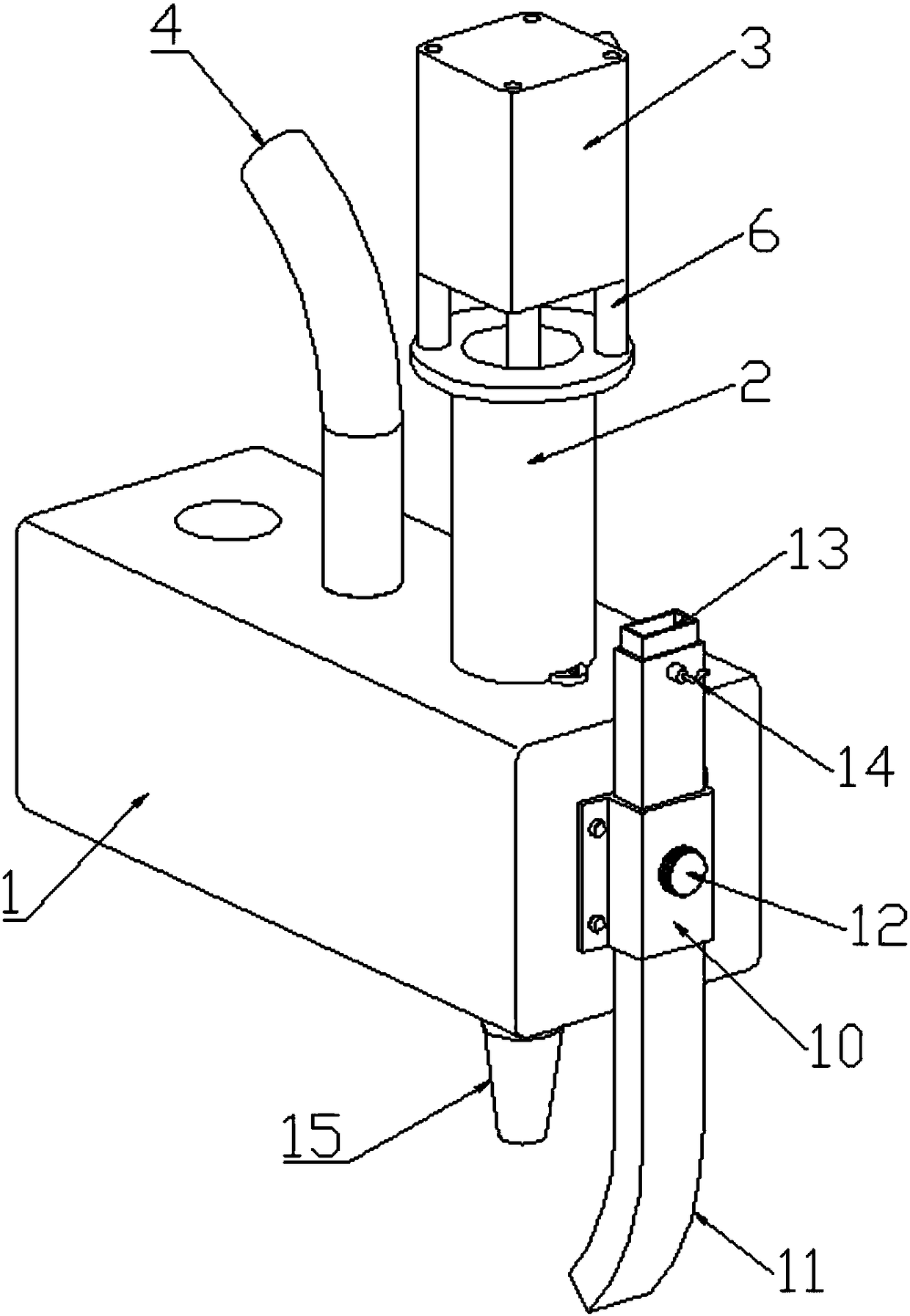

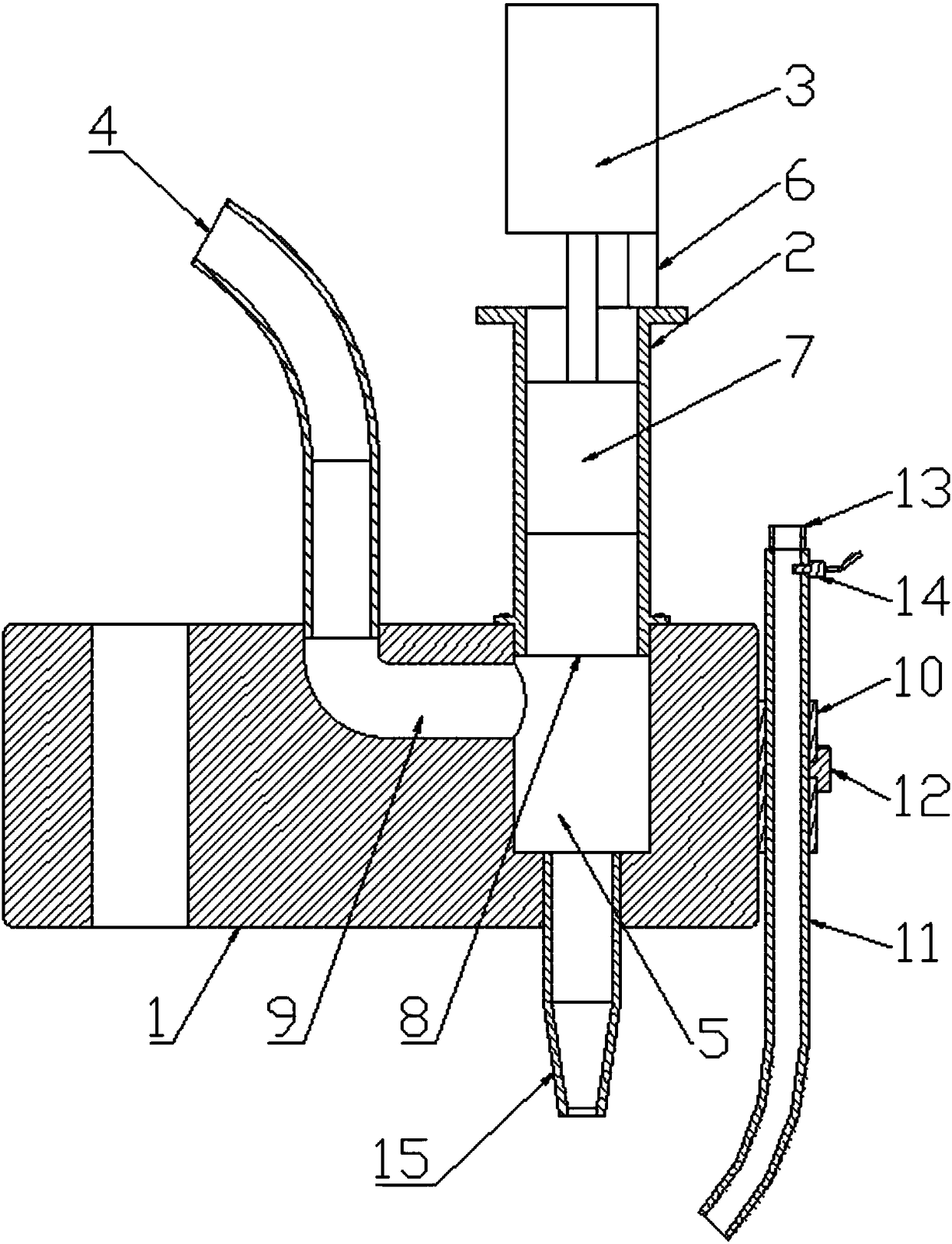

[0019] like figure 1 and figure 2 As shown, an intermittent glue filling device for automatic glue filling of wire harness terminals, including a body 1, a piston barrel 2, a cylinder 3 and a rubber delivery tube 4, a fluid channel 5 is provided in the body 1, and the piston barrel 2 is installed in the fluid channel 5 On the body 1 directly above, the top of the piston cylinder 2 is also provided with a support tube 6, the cylinder 3 is installed on the top of the support tube 6, the output shaft of the cylinder 3 is connected to the piston 7, and the piston 7 is slidably connected in the piston cylinder 2 , and the glue storage chamber 8 is formed between the bottom surface of the piston 7 and the bottom surface of the fluid channel 5, the bottom of the fluid channel 5 is connected with a glue filling pipe 15, and the body 1 is also provided with a glue filling flow channel 9, and the lower end of the glue filling flow channel 9 It communicates with the fluid passage 5, th...

Embodiment 2

[0024] like figure 1 and figure 2 As shown, an intermittent glue filling device for automatic glue filling of wire harness terminals, including a body 1, a piston barrel 2, a cylinder 3 and a rubber delivery tube 4, a fluid channel 5 is provided in the body 1, and the piston barrel 2 is installed in the fluid channel 5 On the body 1 directly above, the top of the piston cylinder 2 is also provided with a support tube 6, the cylinder 3 is installed on the top of the support tube 6, the output shaft of the cylinder 3 is connected to the piston 7, and the piston 7 is slidably connected in the piston cylinder 2 , and the glue storage chamber 8 is formed between the bottom surface of the piston 7 and the bottom surface of the fluid channel 5, the bottom of the fluid channel 5 is connected with a glue filling pipe 15, and the body 1 is also provided with a glue filling flow channel 9, and the lower end of the glue filling flow channel 9 It communicates with the fluid passage 5, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com