QFP (quad flat package) device pin molding fixture and using method thereof

A molding tooling and molding processing technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as inconsistent pins, and achieve the effect of easy processing and use, convenient operation, and consistent shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

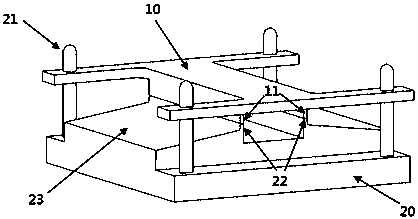

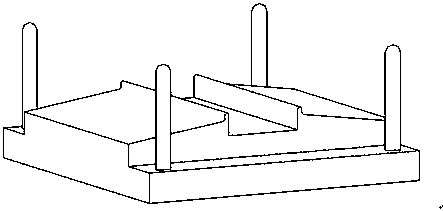

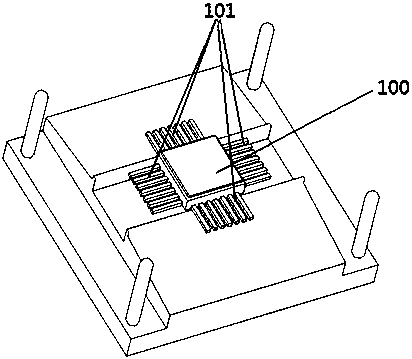

[0037] Such as figure 1 As shown, the present invention provides a kind of QFP device pin molding tooling, and this tooling comprises:

[0038] top cover 10,

[0039] A base 20, the base 20 is provided with a number of fixed columns 21, the top cover 10 is installed above the base 20 through the fixed columns 21, the top cover 10 can move up and down along the fixed columns 21 (vertical to the longitudinal movement of the base);

[0040] The first jaw 11 provided at the bottom of the top cover 10 is composed of two plates perpendicular to the bottom surface of the top cover;

[0041] The second jaw 22 arranged on the top of the base is composed of two plates perpendicular to the top surface of the base;

[0042] Wherein, the first jaw and the second jaw 22 of 11 are relatively aligned and arranged to constitute the clamping part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com