Tailored Welding Tooling and Technology of Overturning Frame Assembly of Hook Arm Cart

A technology of flipping frame and welder, applied in the field of hook arm car assembly, can solve the problems of easy out-of-tolerance, long assembly time, uneven force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further explained below in conjunction with the drawings:

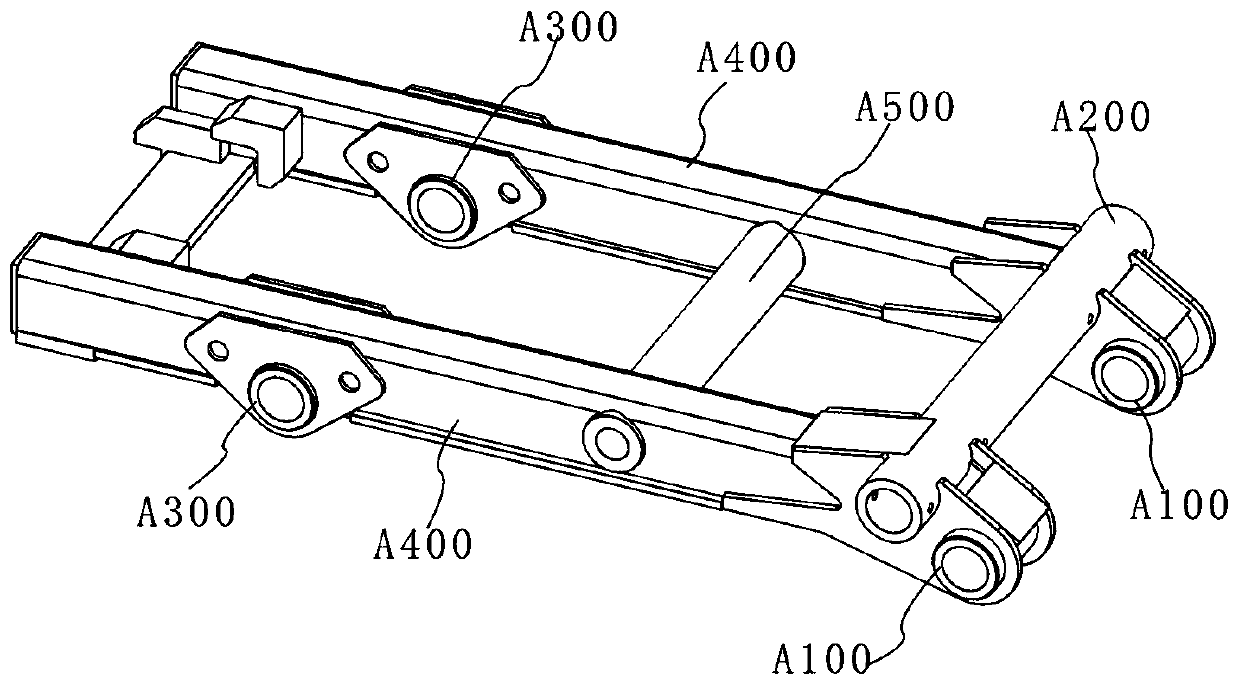

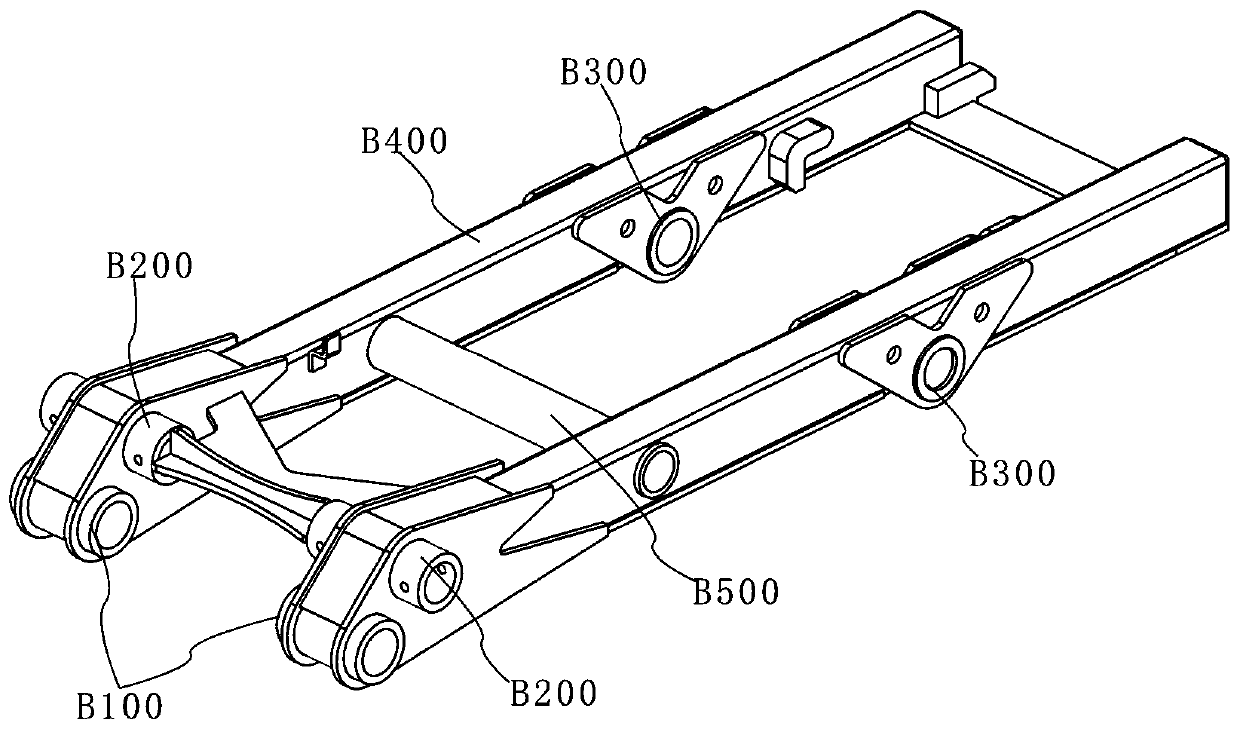

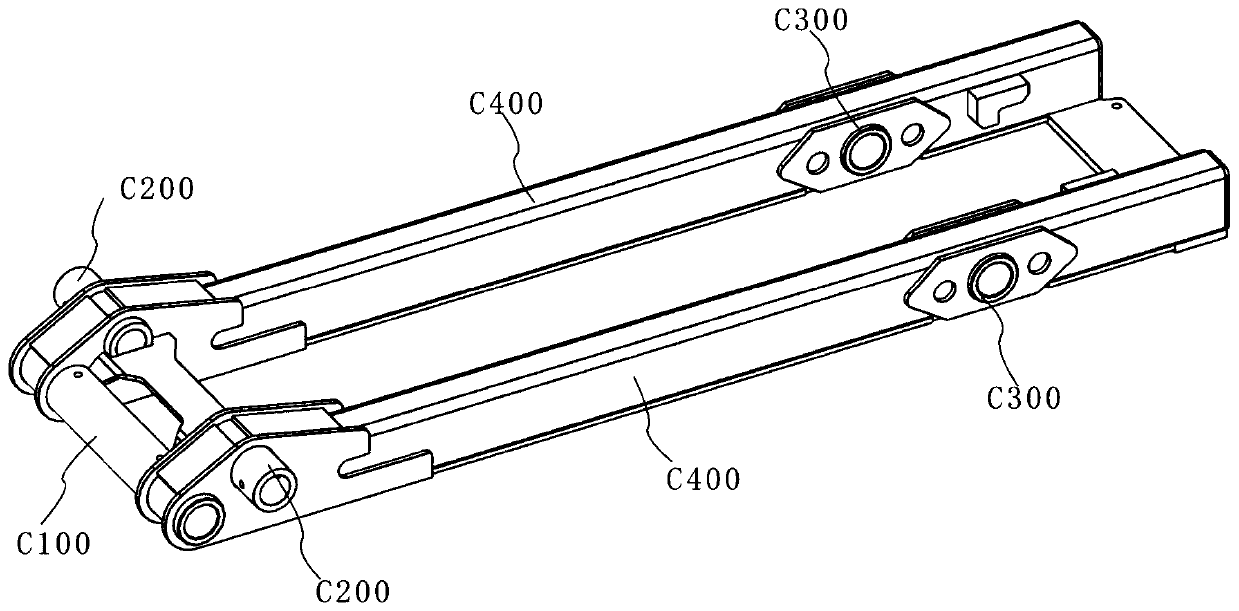

[0058] This embodiment provides a tailor-welded tooling for the flip frame assembly of a hook arm cart. The tailor-welded tooling is a three-in-one tooling suitable for three flip frame products A, B, and C of the same series and different specifications. Flip frame A has the smallest specification, and flip frame C has the largest specification. Among them, the product structure of the flip frame A applicable to the tailor-welded tooling of this embodiment is as follows: figure 1 As shown, it specifically includes two crossbeams A400 arranged in parallel and opposite each other. The guide wheel bushings A200 are transversely arranged between the guide wheel mounting holes at the rear of the two crossbeams A400, and the flip hinge holes at the rear of each crossbeam A400 are respectively connected with flip The shaft sleeve A100, and the swing arm shaft sleeve A300 are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com