Gluing and coil mounting device for perforating bullet

A coil device and perforating projectile technology, which is applied to the device, coating, metal processing and other directions of coating liquid on the surface, can solve the problem of poor uniformity of artificial glue coating, and achieve efficient positioning method, high positioning accuracy, Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

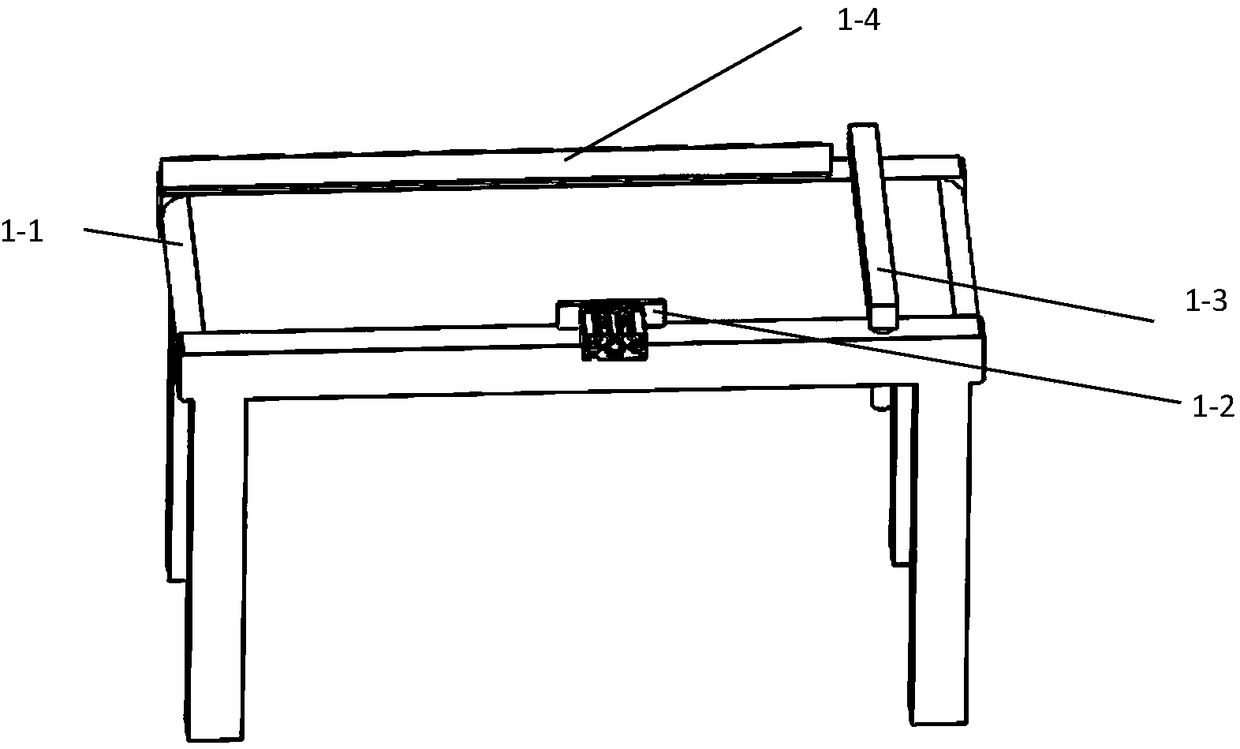

[0021] The stamped perforating bullets are regularly placed in the trays. In this embodiment, the size of the tray is 5*10, and 50 pieces are placed on a single tray. The specific implementation is not limited by the size of the tray.

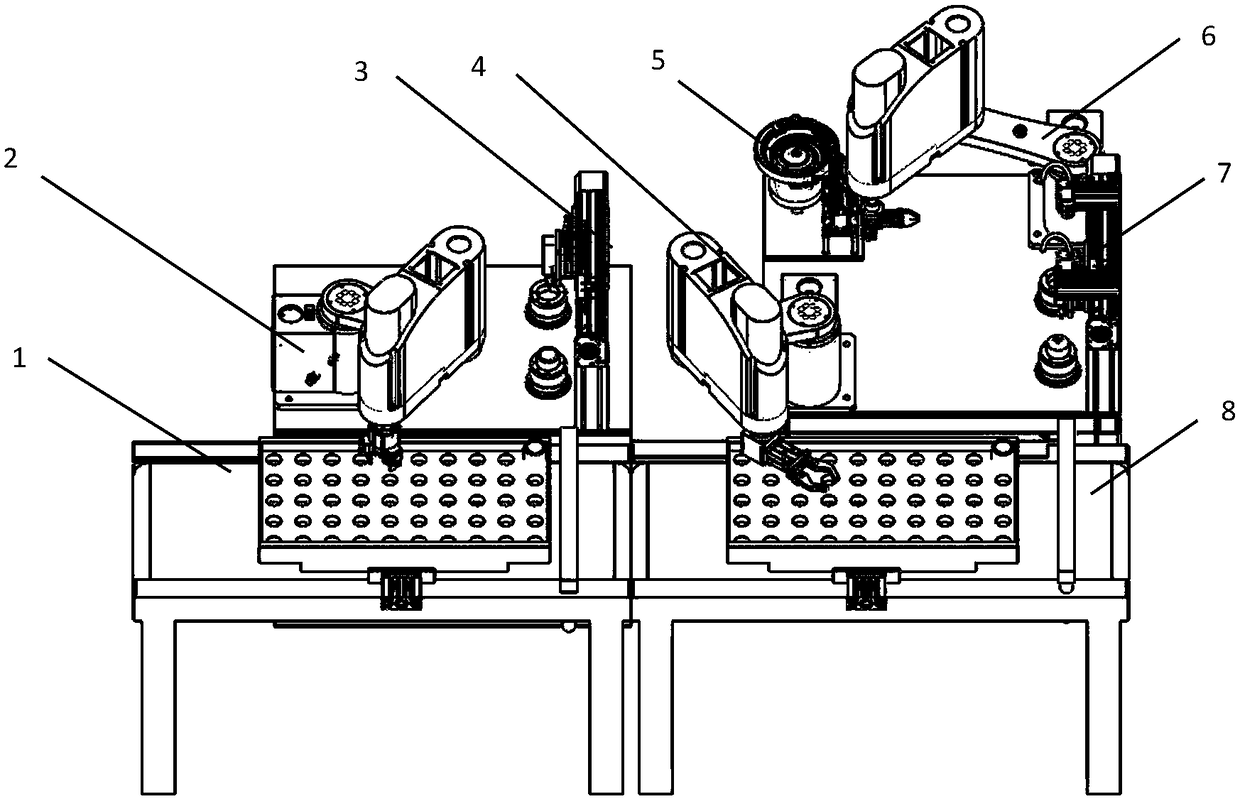

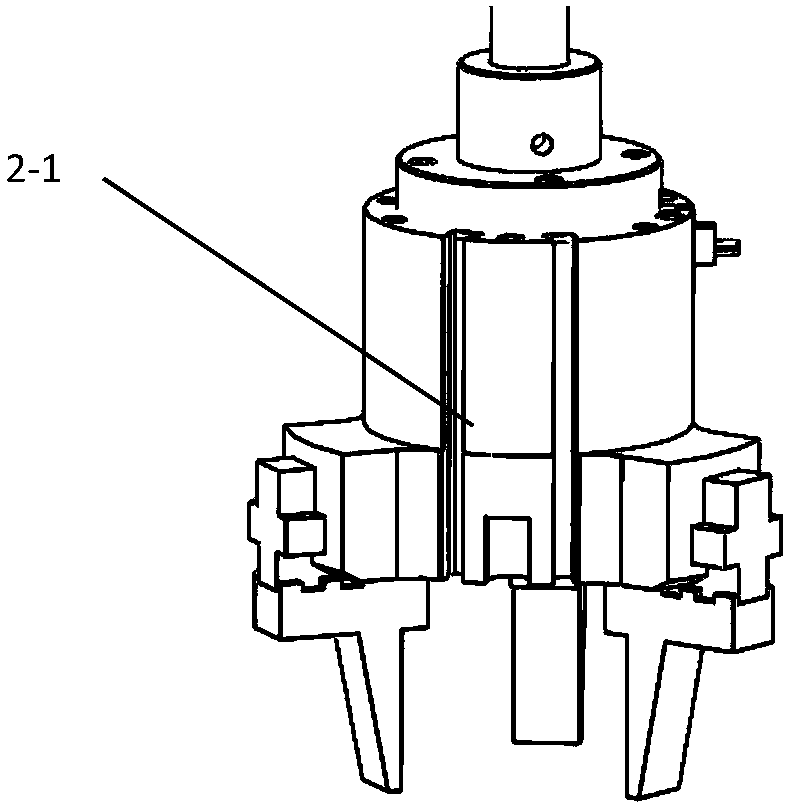

[0022] Such as figure 1 As shown, a glue-coating coil device for perforating bullets includes a glue-coating station and a coil-loading station. The glue-coating station and the coil-loading station are arranged in sequence, and the glue-coating station includes a first conveying mechanism 1 , the first conveying robot 2 and the first gluing mechanism 3, the first gluing mechanism 3 and the first conveying robot 2 are arranged on the same side of the first conveying mechanism 1, the first gluing mechanism 3 and the first conveying robot 2 Installed on the upper end surface of the placement table, the first transport robot 2 is used to transport perforating bullets between the first gluing mechanism 3 and the first transport mechanism 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com