Four-cavity iron sheet implanting and overturning takeout tool

A technology of iron sheets and jigs, which is applied in the field of machinery, can solve the problems of high labor cost consumption, inconvenient operation, and low degree of automation, and achieve the effects of improving operational performance, high production efficiency, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

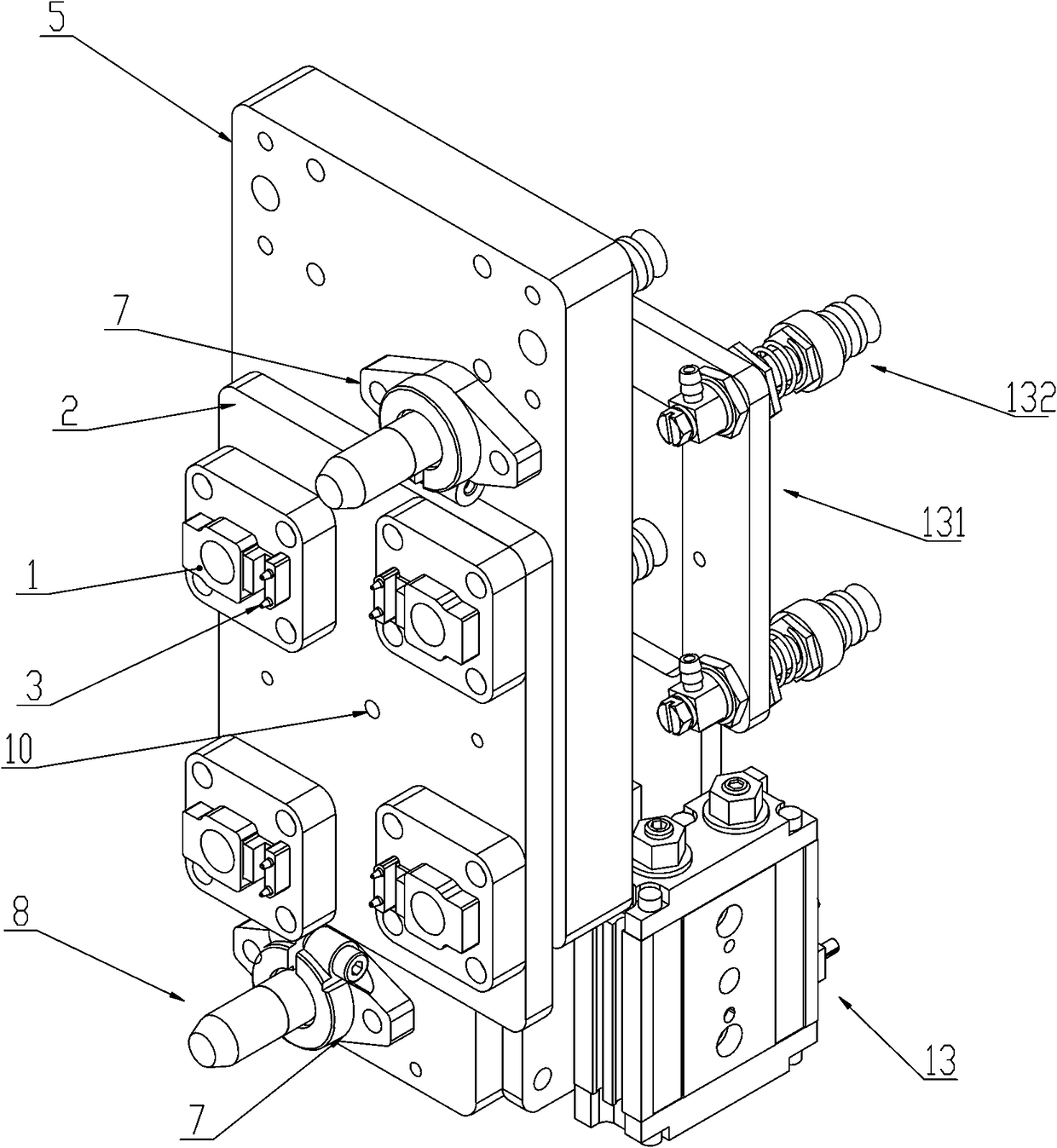

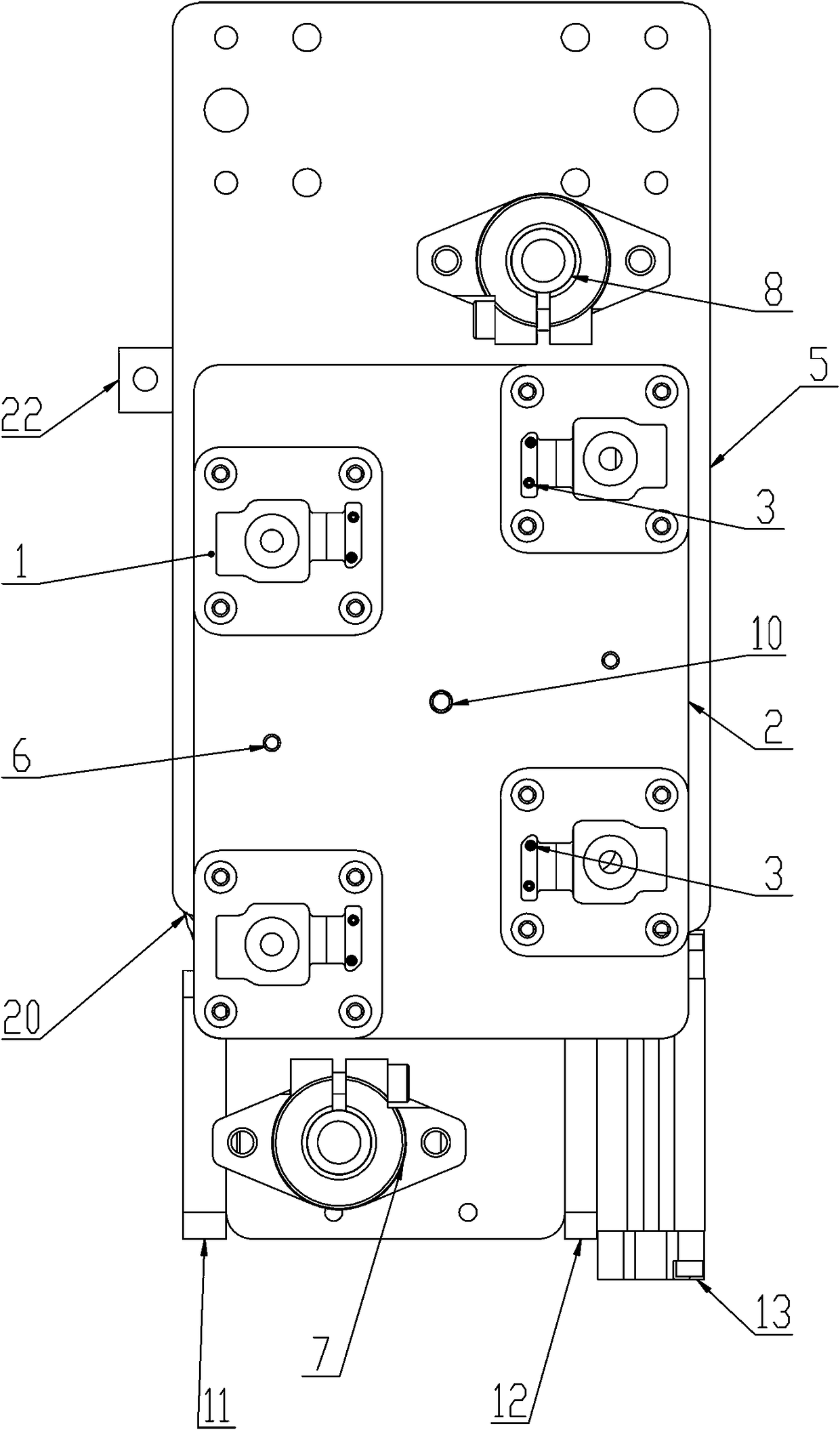

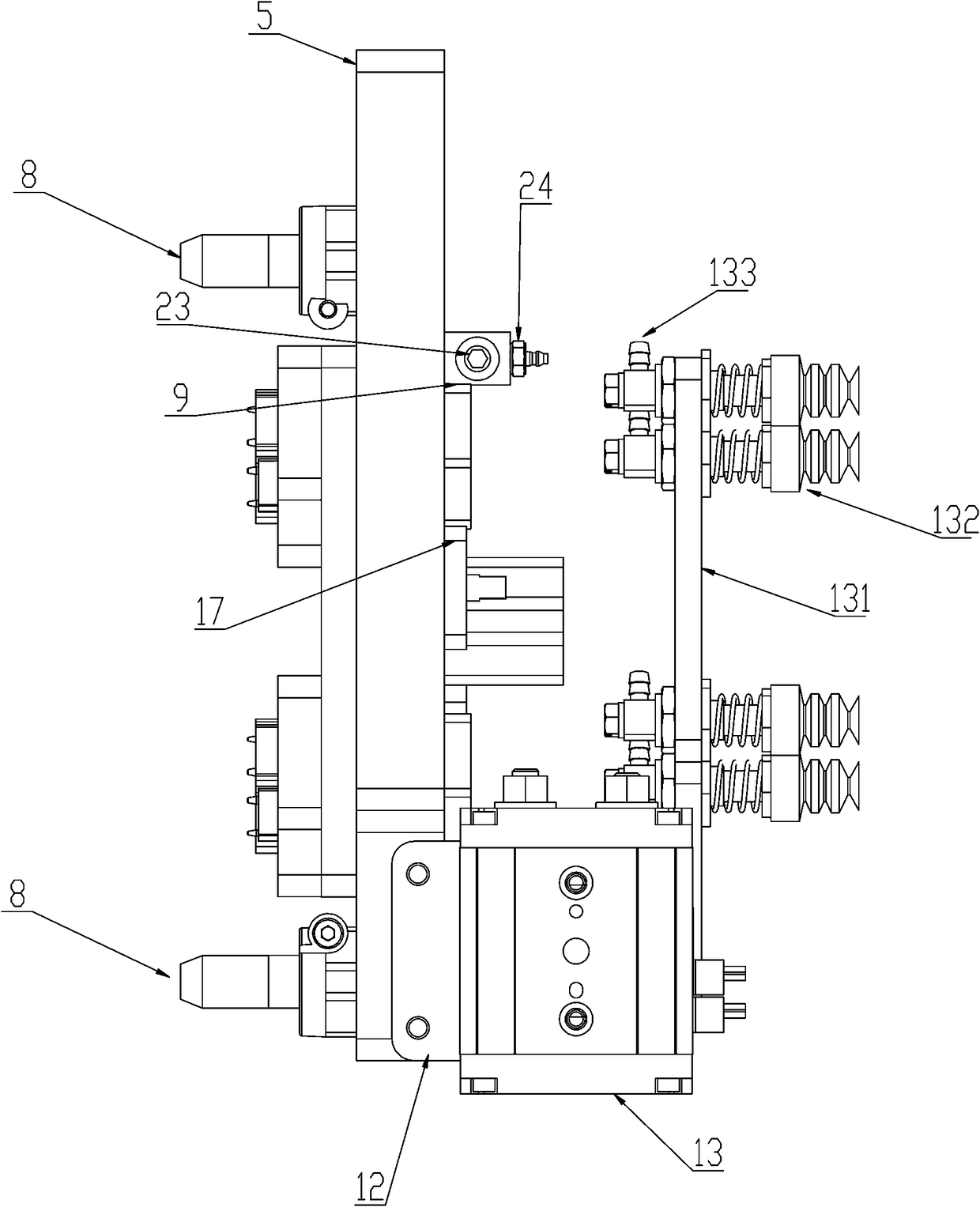

[0025] like Figure 1~4 As shown, a 4-hole iron sheet implantation and flipping out jig, the jig plate 5 includes an operating surface and a mounting surface, the operating surface of the jig plate 5 is provided with an iron sheet implanting device 1, and the jig plate 5 The installation surface is provided with an overturning mechanism and an ejecting cylinder 10 that provides an ejecting force for the iron sheet implantation device 1. One end of the overturning mechanism is fixedly connected to the jig plate 5, and the other end of the overturning mechanism is connected to the top of the overturning mechanism mounting plate 131. On one side, on the other side of the flipping mechanism mounting plate 121, several flipping rods 20 for taking out workpieces are respectively arranged; An iron sheet implantation station includes a positioning pin 3 for limiting the position of the workpiece, and an iron sheet chamber for accommodating the iron sheet.

[0026] Specifically, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com