Automatic chuck for small hardware grinding machine

A hardware and grinding machine technology, which is applied in the direction of grinding machines, grinding workpiece supports, metal processing equipment, etc., can solve the problems of reducing the clamping stability of grinding machines, reducing the accuracy of workpieces, and low positioning accuracy, so as to improve applicability and Positioning accuracy, improved clamping stability, and good clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

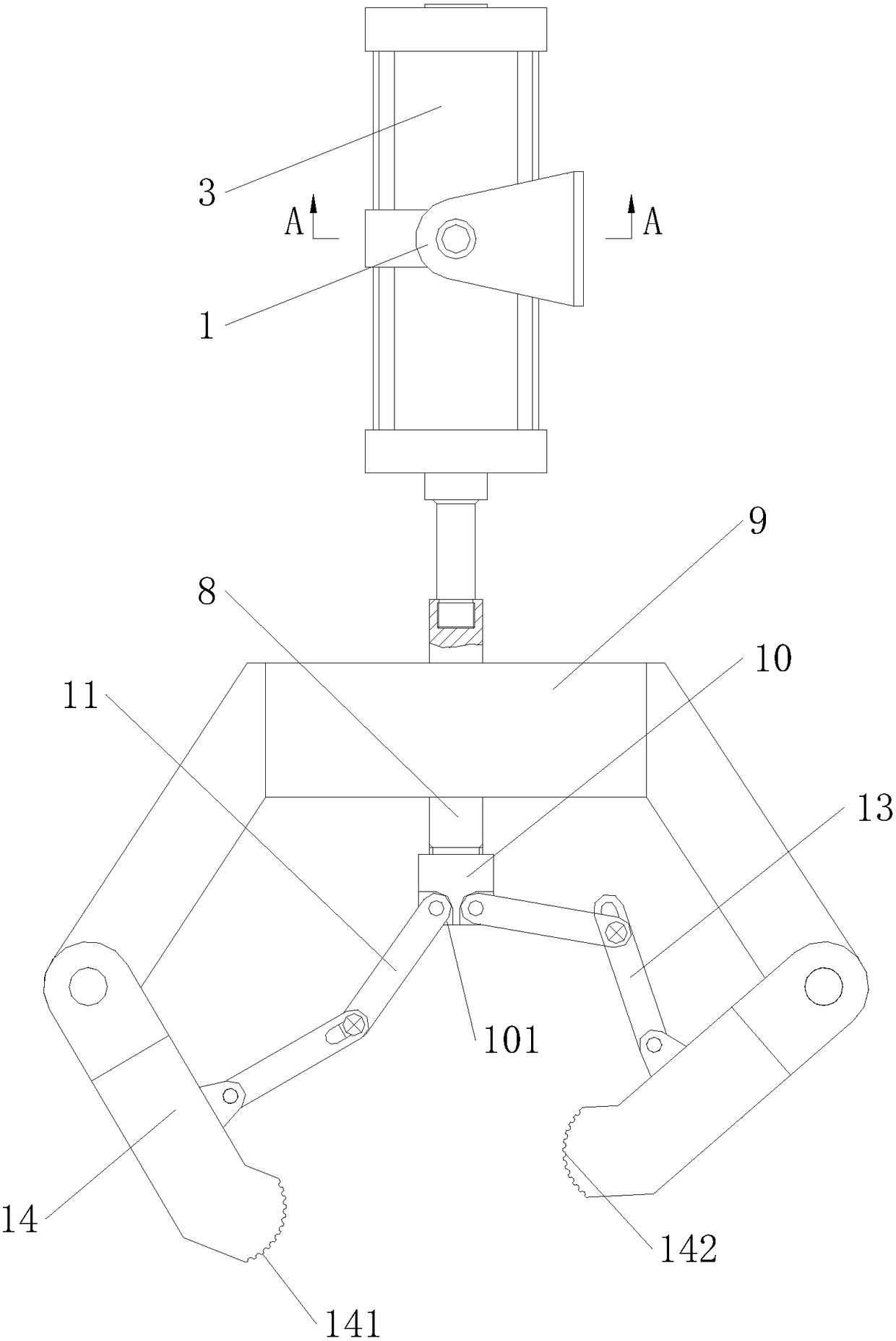

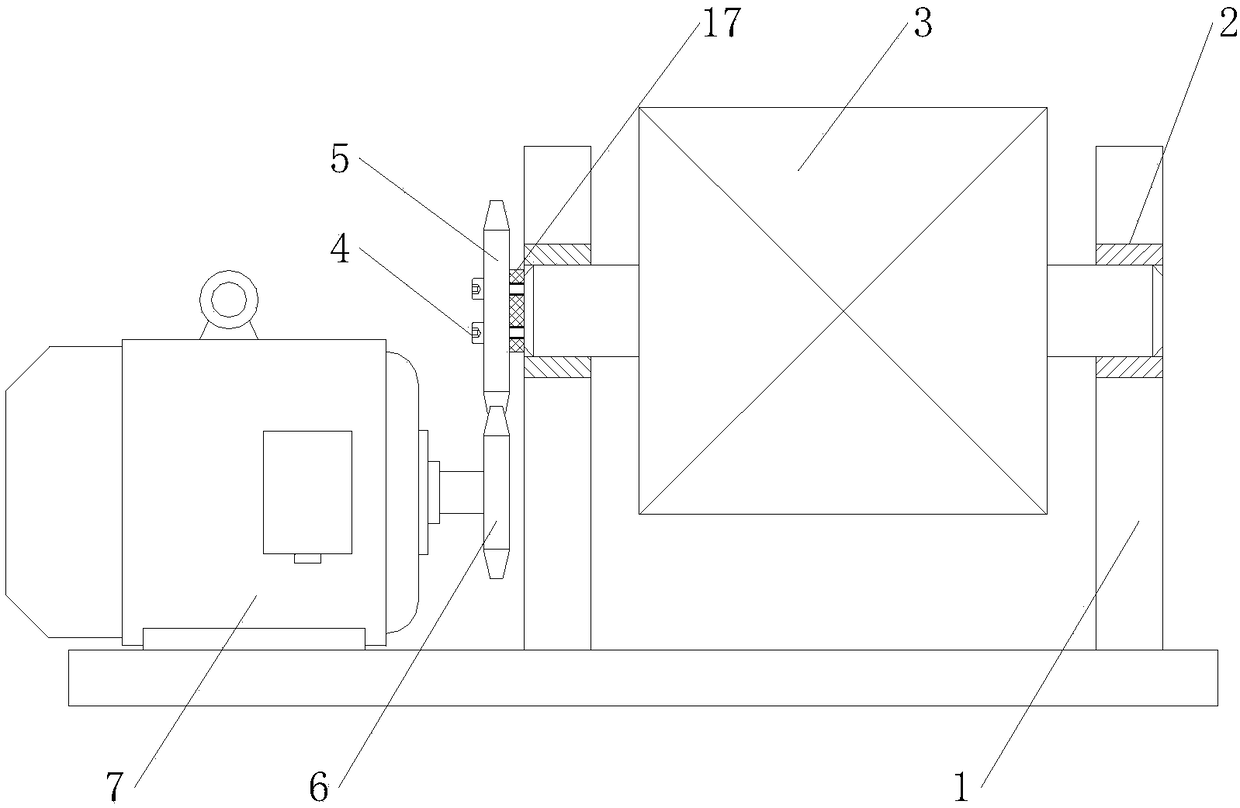

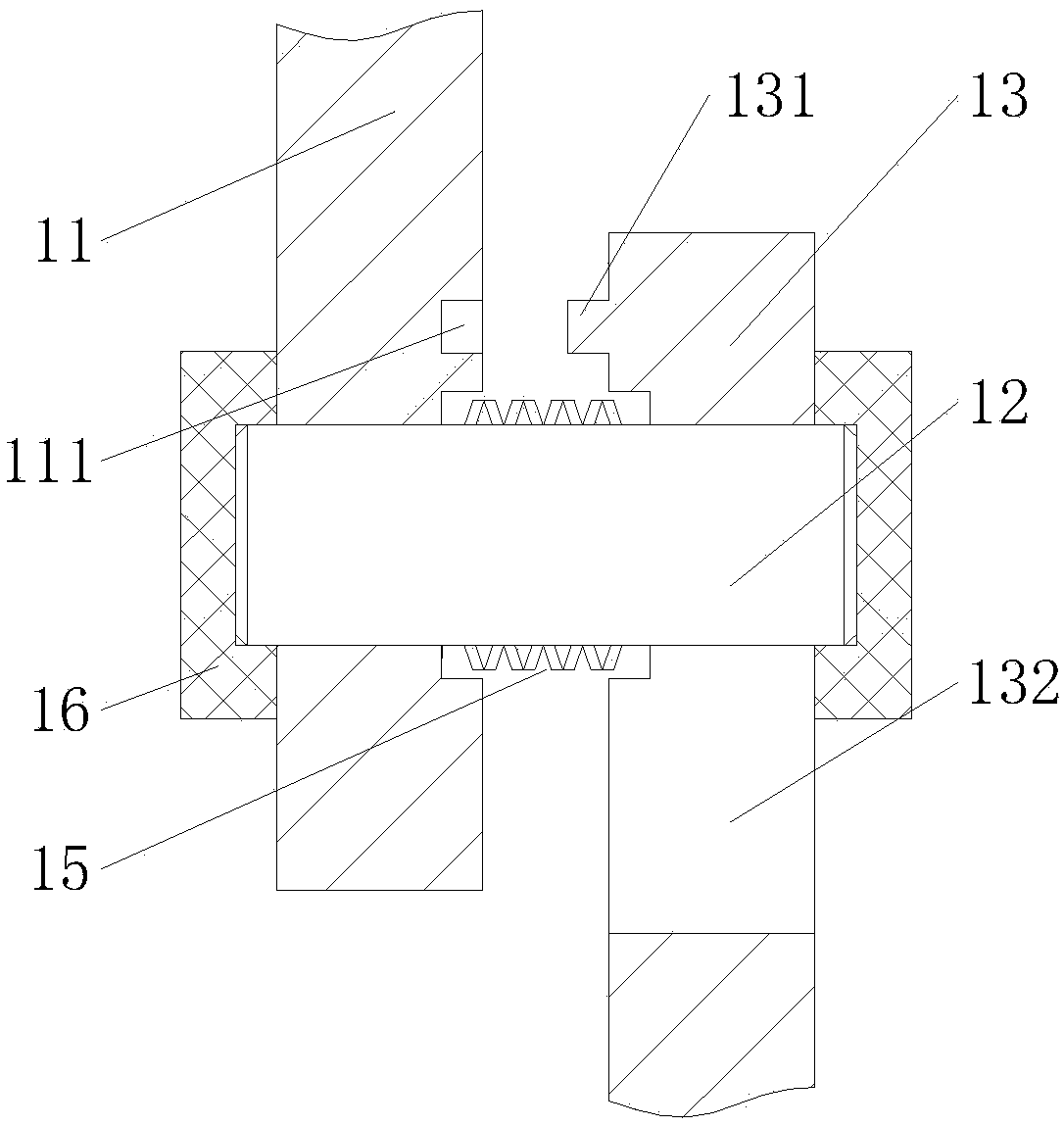

[0016] Example. An automatic chuck for a small hardware grinding machine, which is composed of figure 1 As shown, it includes a support frame 1, the support frame 1 is connected with a middle swing cylinder 3 through a copper sleeve 2, and the outside of the swing shaft on one side of the middle swing cylinder 3 is connected with a rotating gear 5 through a plurality of screws 4, and the lower end of the rotating gear 5 The driving gear 6 is engaged with the drive gear 6, the driving motor 7 is connected to the inner side of the driving gear 6, and the extension shaft of the middle swing cylinder 3 is connected to the telescopic rod 8. A rod head 10 is connected, and locking screws are arranged on the side wall of the rod head 10. A plurality of mounting steps 101 are evenly distributed on the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com