Toothed rail driving system

A driving system and cog-rail technology, applied in the field of rail vehicles, can solve problems such as wheels and rails slipping, and achieve the effect of rapid transportation and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

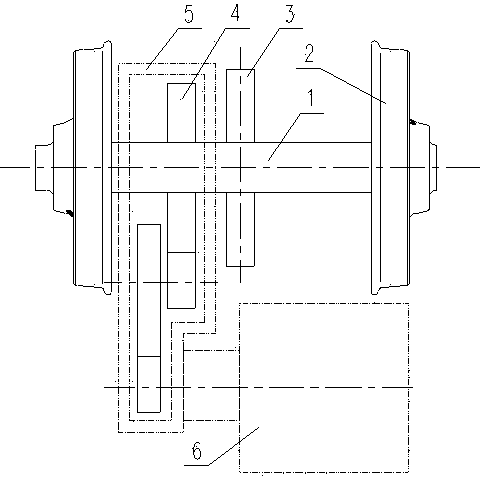

[0019] Such as figure 1 As shown, a rack drive system includes an axle 1 and wheels 2 installed at both ends of the axle 1, and also includes a rack drive gear 3, a reducer and a traction motor 6, and the rack drive gear 3 is fixed in an interference fit form Installed in the middle of the axle 1, the housing 5 of the reducer is hugged on the axle 1 through tapered roller bearings on both sides and positioned axially, the input shaft of the reducer is connected with the output shaft of the traction motor 6, and the deceleration The transmission gear 4 of the reducer is assembled as the output shaft of the reducer by its output end gear and the axle shaft 1 in the form of interference fit. The traction motor 6 is suspended on the vehicle bogie.

[0020] The transmission gear 4 of the speed reducer is in the form of a two-stage reduction gear.

[0021] There is no cog on the track with a slope not greater than 40‰, and the traction torque generated by the traction motor 6 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com