A wire rope degreasing device

A technology of steel wire rope and installation groove, which is applied in hoisting devices, clockwork mechanisms, etc., can solve the problems that the winch cannot pull the vehicle, reduce the traction force of the winch, and occupy construction personnel, etc., to solve the problem of slipping and serious drop of traction force, and to avoid the working environment , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

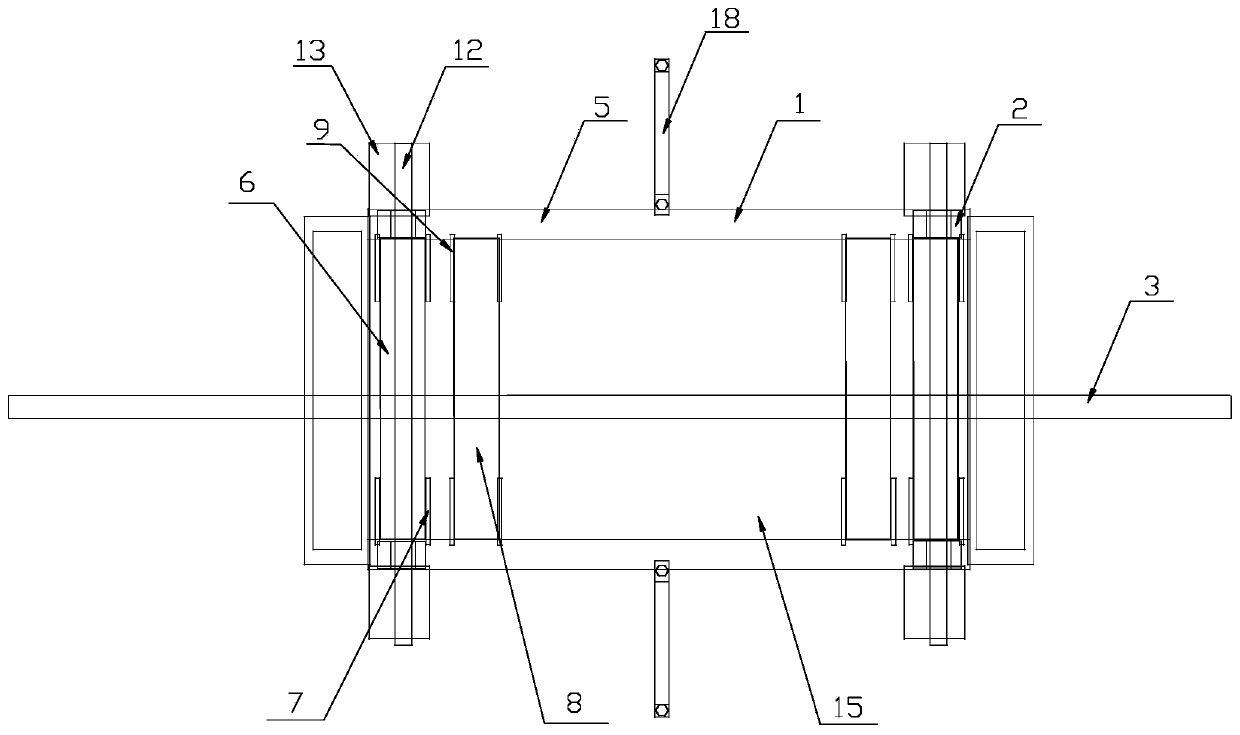

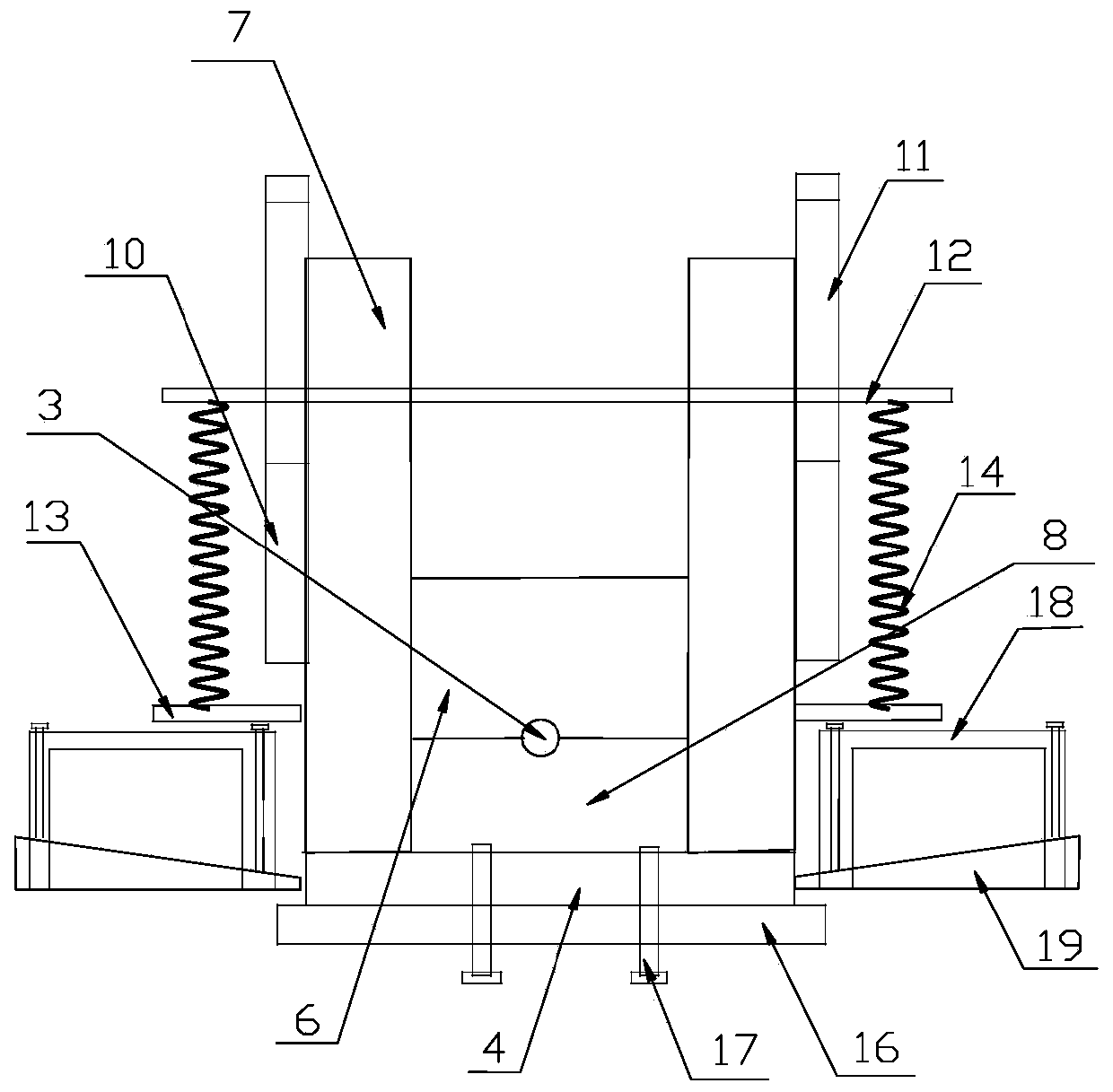

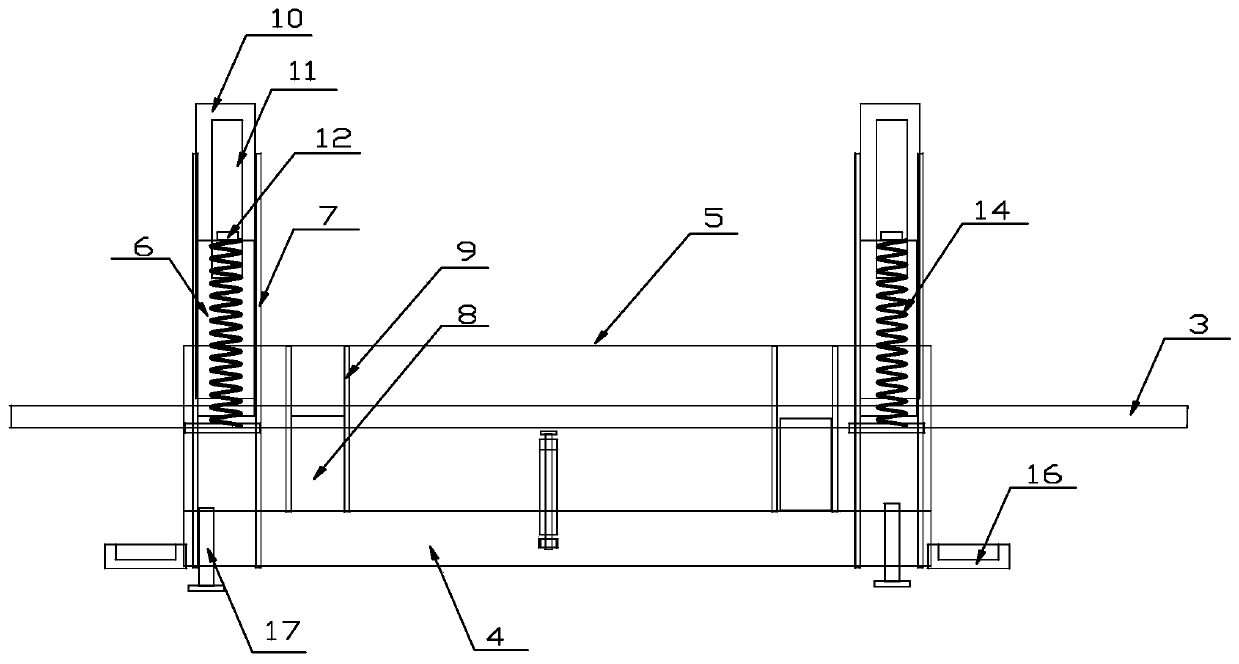

[0025] like Figure 1-3 As shown, a wire rope degreasing device includes a base assembly 1 and at least two degreasing mechanisms 2, the degreasing mechanisms 2 are located above the base assembly 1, and are used to remove the antirust oil on the surface of the wire rope 3. At the same time, at least two degreasing mechanisms 2 are arranged at intervals along the extending direction of the steel wire rope 3 , that is to say, the device can degrease the steel wire rope 3 multiple times to improve the cleanliness of the steel wire rope 3 .

[0026] Described base assembly 1 comprises bottom plate 4 and two side plates 5, and described two side plates 5 are respectively positioned at the both sides of bottom plate 4 to encircle cavity, and base plate 4 and side plate 5 joints are set as wedge shape, with Improve fit. The degreasing mechanism 2 includes a matched first degreasing assembly and a second degreasing assembly, the first degreasing assembly includes a first belt 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com