Specific sulfur recovery treatment device for insoluble sulfur solvent

A processing device and sulfur technology, which are applied in the preparation/purification of sulfur compounds, sulfur, inorganic chemistry, etc., can solve the problems of cumbersome sulfur recovery process and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present application will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present application uses technical means to solve technical problems and achieve technical effects.

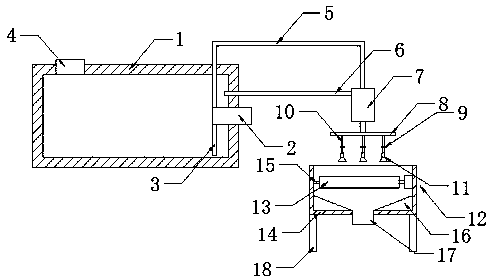

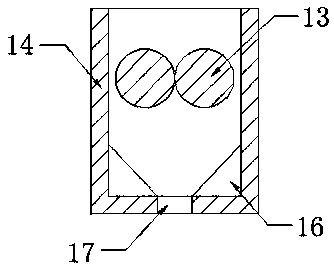

[0016] Such as figure 1 , figure 2 As shown, the present invention provides a special insoluble sulfur solvent treatment device for recovering sulfur, comprising a storage box 1 and a connection box 7, one side of the top of the storage box 1 is provided with a liquid sulfur inlet 4, and one side of the storage box 1 is A through hole is opened, and a water pump 2 is fixed in the through hole. The liquid inlet end of the water pump 2 is fixedly connected with one end of the sulfur inlet pipe 3, and the other end of the sulfur inlet pipe 3 is located at the bottom of the storage tank 1. The liquid outlet of the water pump 2 end is fixedly connected with one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com