Production process of anti-mosquito coral fleece composite fabric

A composite fabric and production process technology, applied in the field of fabrics, can solve the problems of cumbersome operation, inability to collect lint, and low production quality, and achieve the effects of improving production efficiency, ensuring processing quality, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

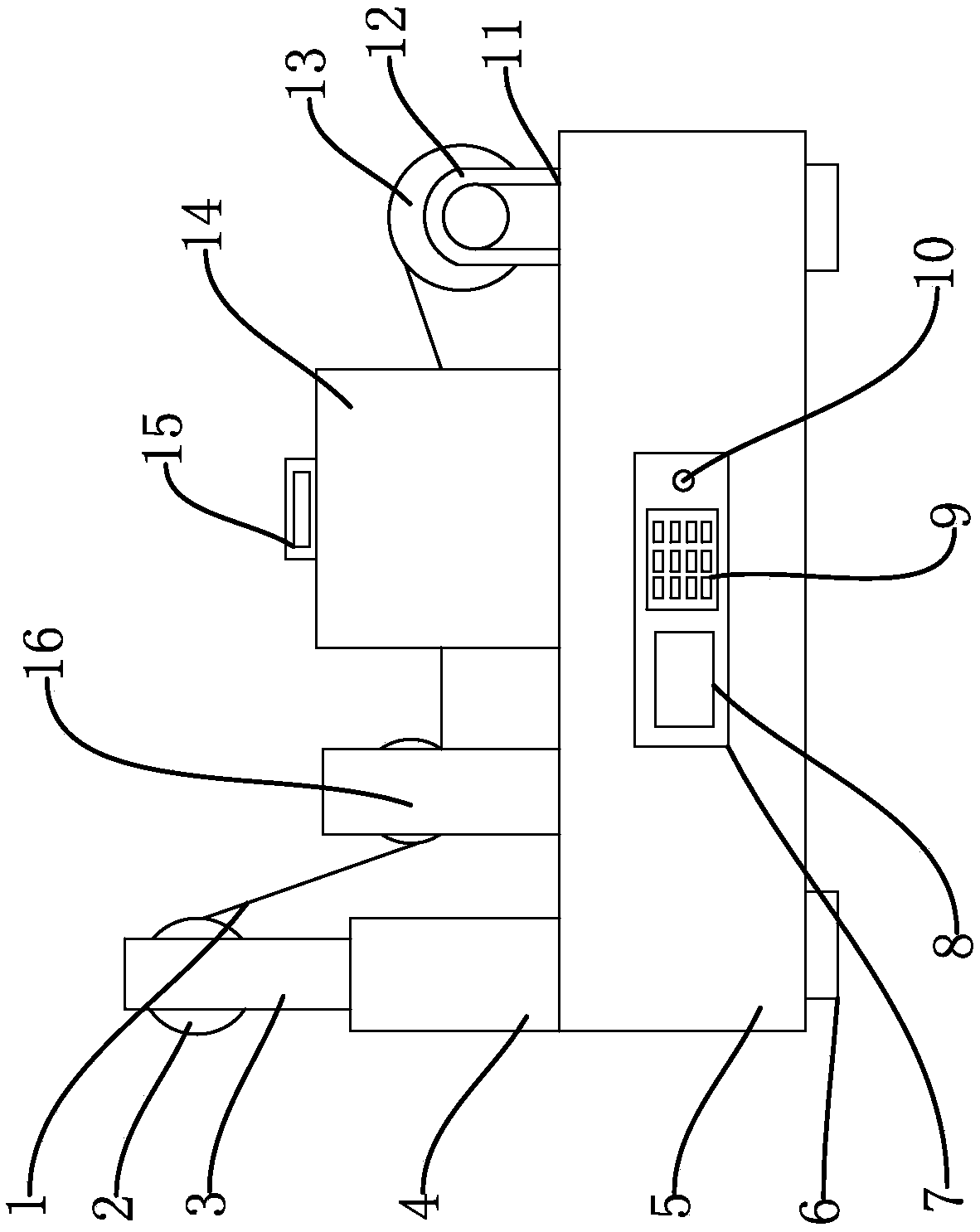

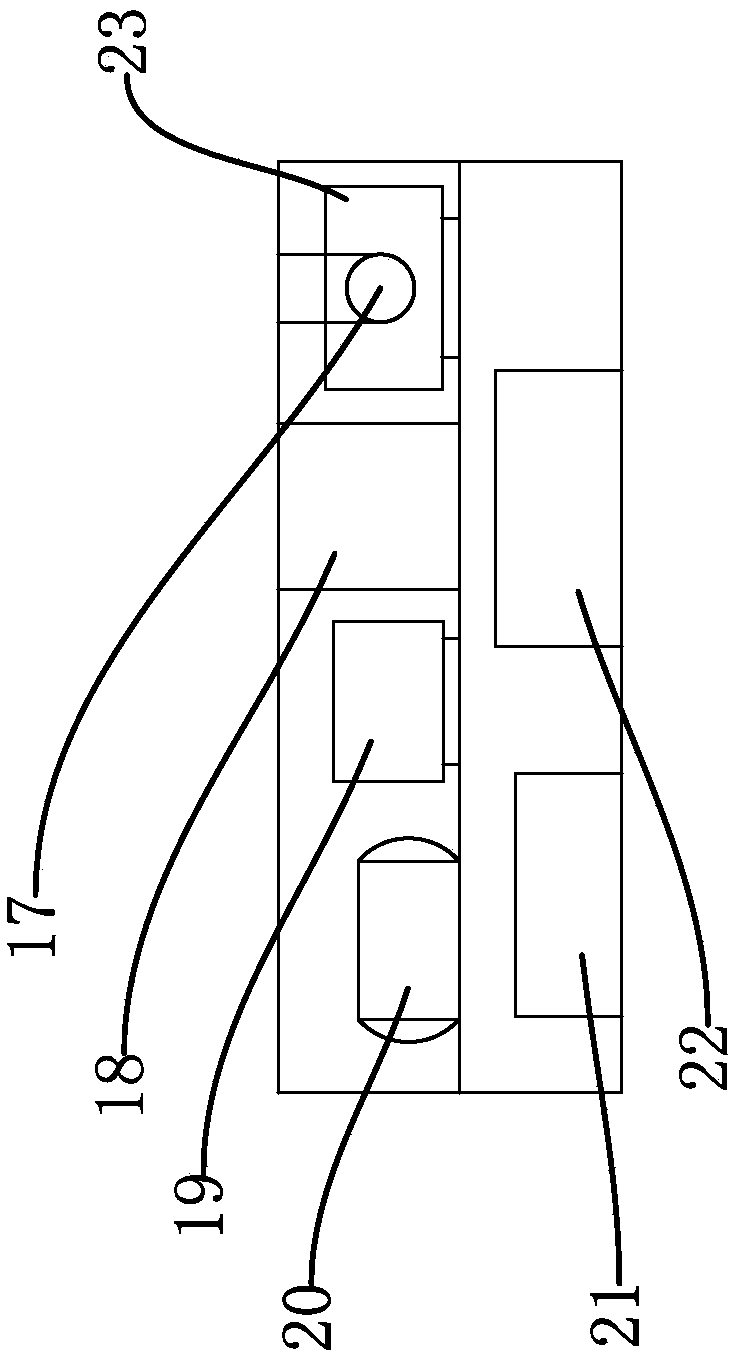

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

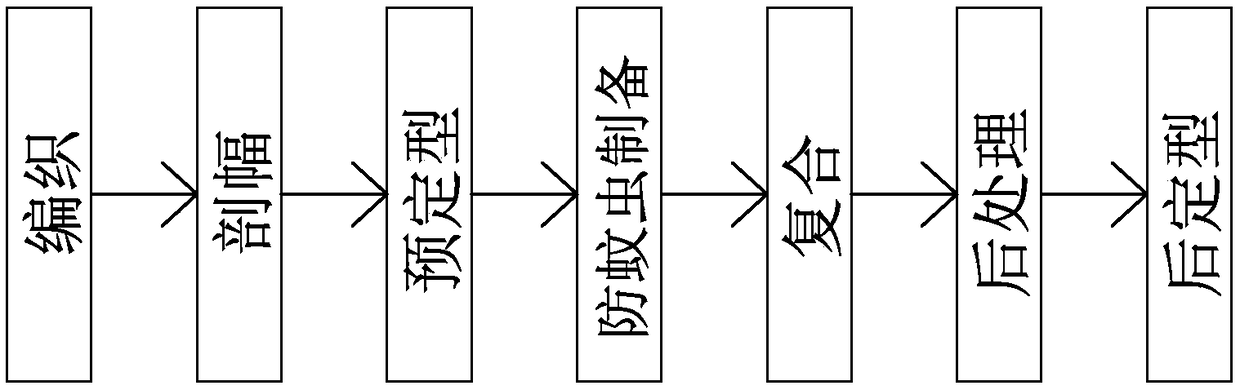

[0032] Such as Figure 1-4 Shown, a kind of production technology of anti-mosquito coral velvet composite fabric, this production technology comprises the following steps:

[0033] S1. Weaving: Use 150D / 288F polyester ultra-fine low-elasticity yarn as the base yarn, use ordinary polyester monofilament as the wool yarn, and place the two in a warp knitting machine for weaving;

[0034] S2. Cutting width: cutting through cutting pile device to obtain gray cloth;

[0035] S3, pre-setting: the prepared single-side plush gray cloth is pre-shaped by a sizing machine, setting the pre-setting temperature in the sizing machine and controlling the running speed of the single-side plush gray cloth to obtain a predetermined type gray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com