Dry-wet separation-type preshrinking device

A dry and wet separation and pre-shrinking technology, which is applied in the processing of textile material equipment configuration, heating/cooling fabric, textile material processing, etc., can solve the problems of affecting the service life of components, poor pre-shrinking effect, and short service life of devices To achieve the effect of improving fabric quality, improving service life, and good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

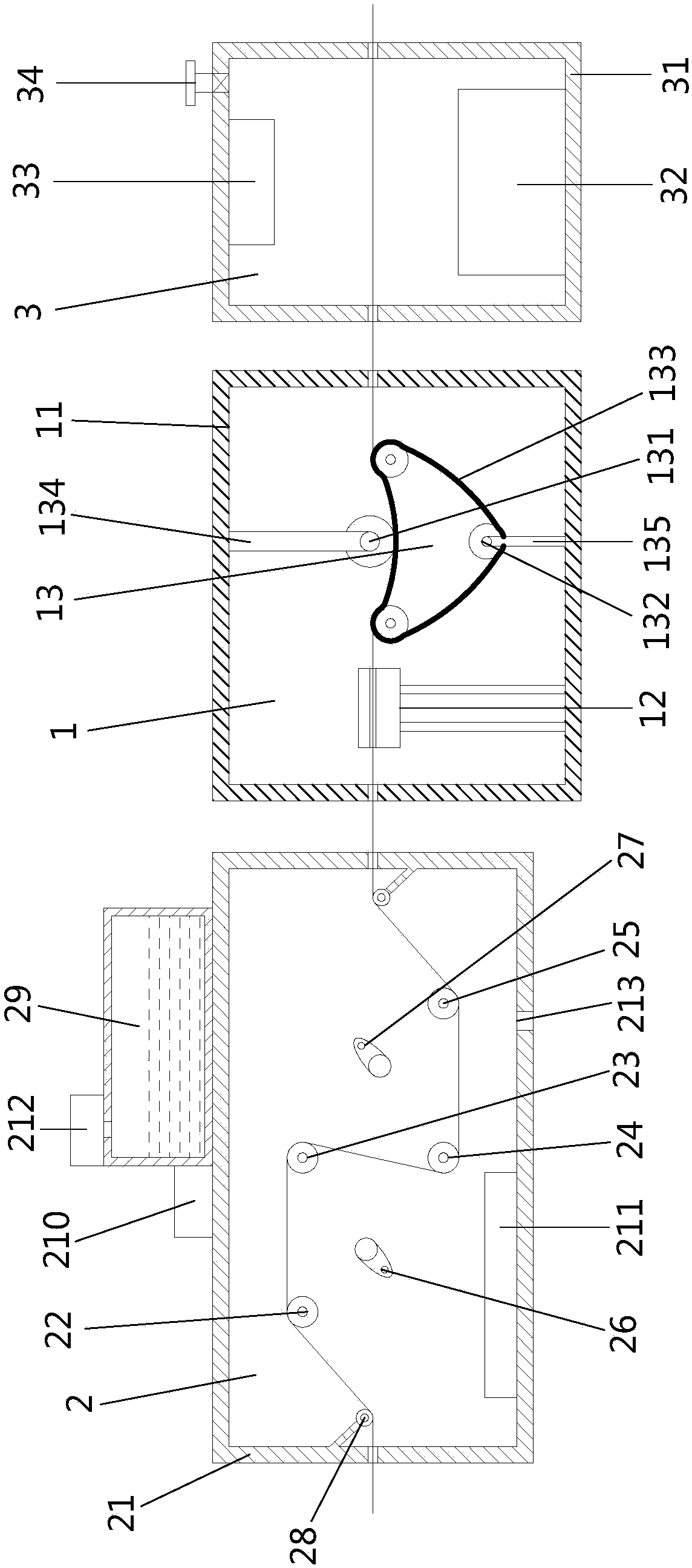

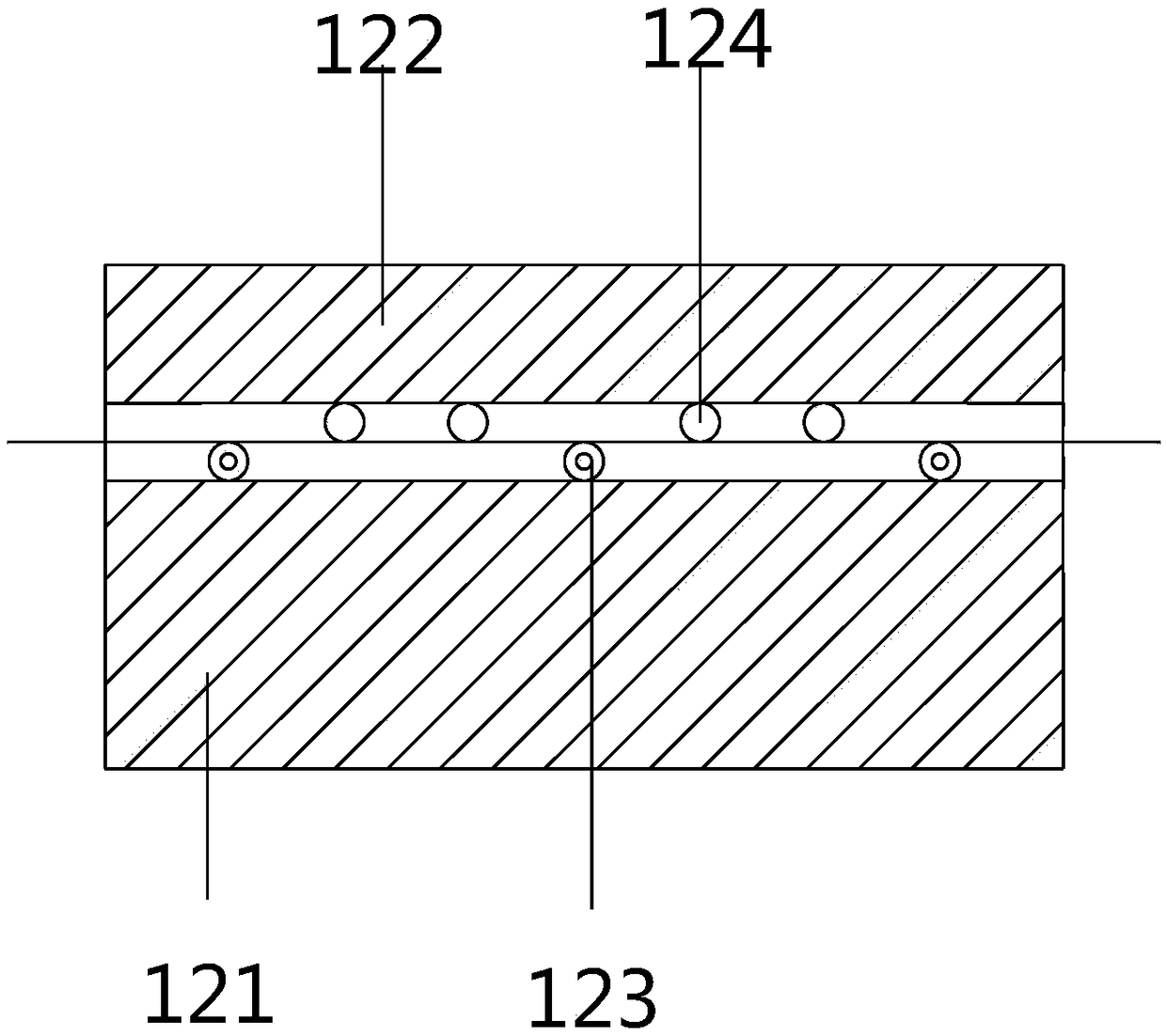

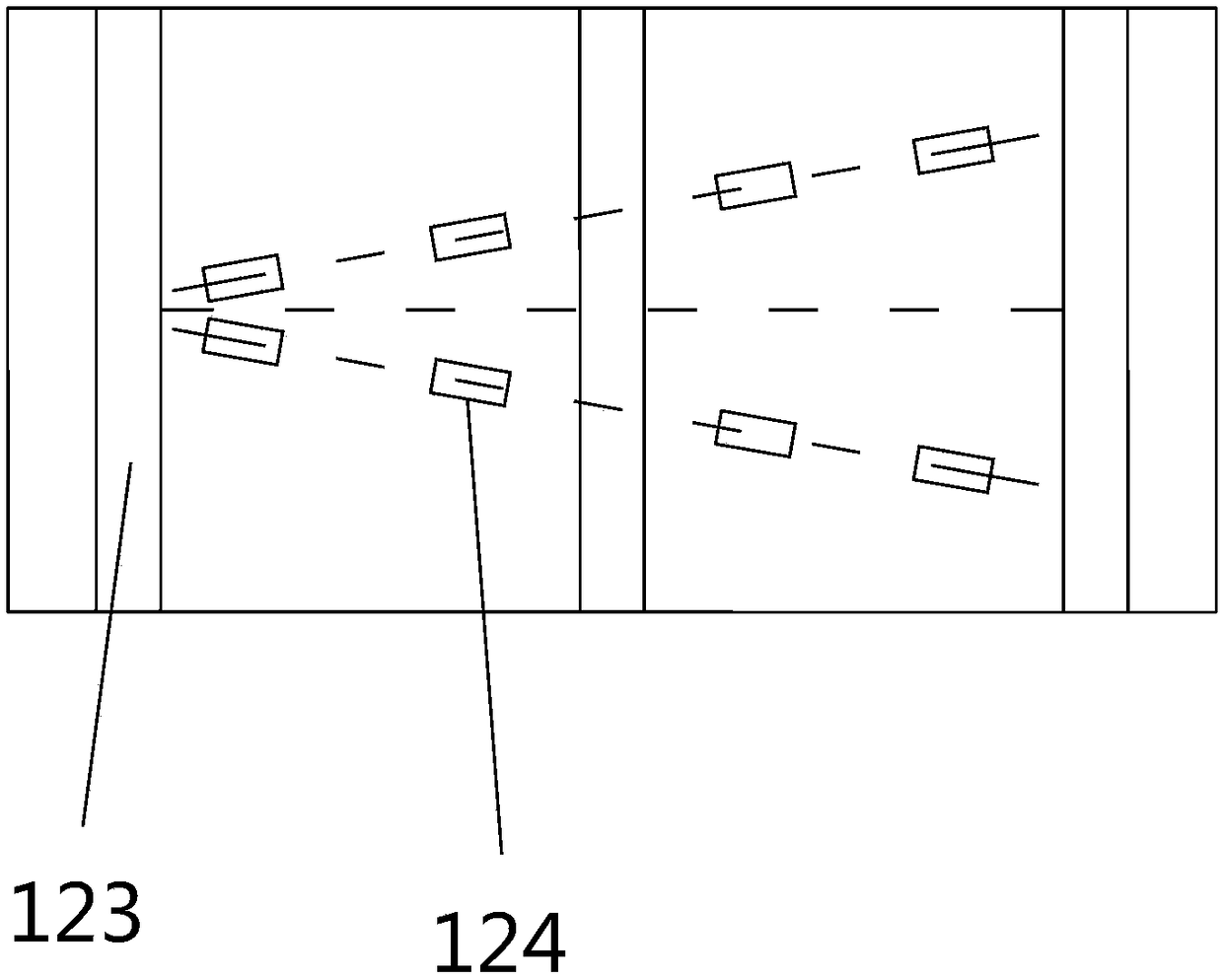

[0022] Embodiment: a dry-wet separation pre-shrinking device, the structure is as Figure 1 to Figure 3 As shown, it includes a pre-shrinking mechanism 1, and the two sides of the pre-shrinking mechanism 1 are respectively provided with a moisture supply mechanism 2 and a drying mechanism 3; The first drive roller 22, the second drive roller 23, the third drive roller 24 and the fourth drive roller 25 arranged in a misplaced position, the plane formed by the second drive roller 23 and the third drive roller 24 is perpendicular to the bottom surface of the humidification box 21, The front and rear sides of the plane where the second drive roller 23 and the third drive roller 24 are located are respectively provided with a first steam spray nozzle 26 and a second steam spray nozzle 27, and guide rollers 28 are provided on both sides of the feed and discharge inside the wet box body 21; The pre-shrinking mechanism 1 includes a pre-shrinking box 11, and the pre-shrinking box 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com