Separate layer fracturing tool and construction process thereof

A layer-fracture and tool technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of difficult perforation refinement, poor tool wear resistance, difficult positioning and other problems, and achieve easy cleaning. , The effect of uniform force and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

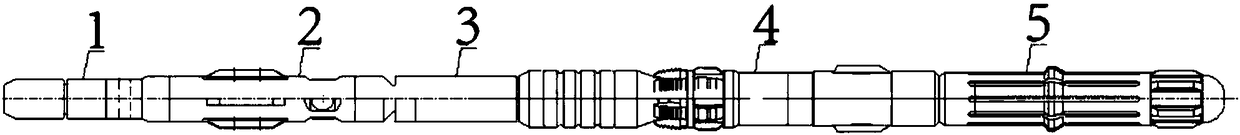

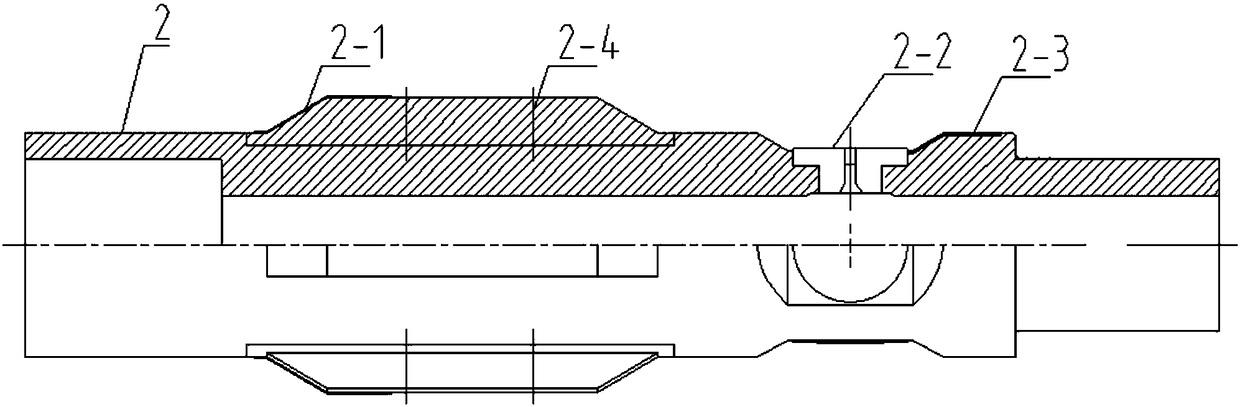

[0044] Such as Figures 1 to 9 As shown, a layered fracturing tool includes a hand-off joint 1, a righting spray gun 2, a circulation valve 3, a bottom packer 4, and a collar positioner 5. Both ends of the righting spray gun 2 are respectively connected to the hand-off joint 1, The circulation valve 3 and the two ends of the bottom packer 4 are respectively connected with the other end of the circulation valve 3 and the collar positioner 5 .

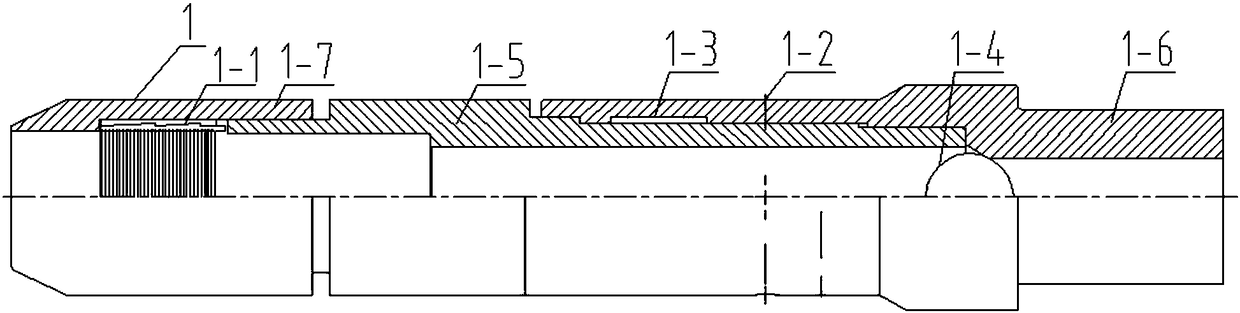

[0045] The drop-hand joint 1 is composed of the drop-hand upper joint 1-7, the shear pin 1-2, the salvage fish neck 1-3, the ball 1-4, the connection joint 1-5 and the drop-hand joint 1-6, and the connection joint 1- 5. One end is connected with the upper joint 1-7 of the hand, the other end of the joint 1-5 is connected with the joint 1-6 of the lower hand through the shear pin 1-2, and the fish neck 1-3 is set on the lower joint 1-6 of the hand. , the ball 1-4 is placed in the inner cavity of the discarding joint 1 and can be in conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com