Low-pressure fuel supply system of diesel

A fuel supply and diesel engine technology, applied in charging systems, mechanical equipment, engine components, etc., can solve problems such as wax precipitation, and achieve the effects of convenient use, high heating efficiency and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

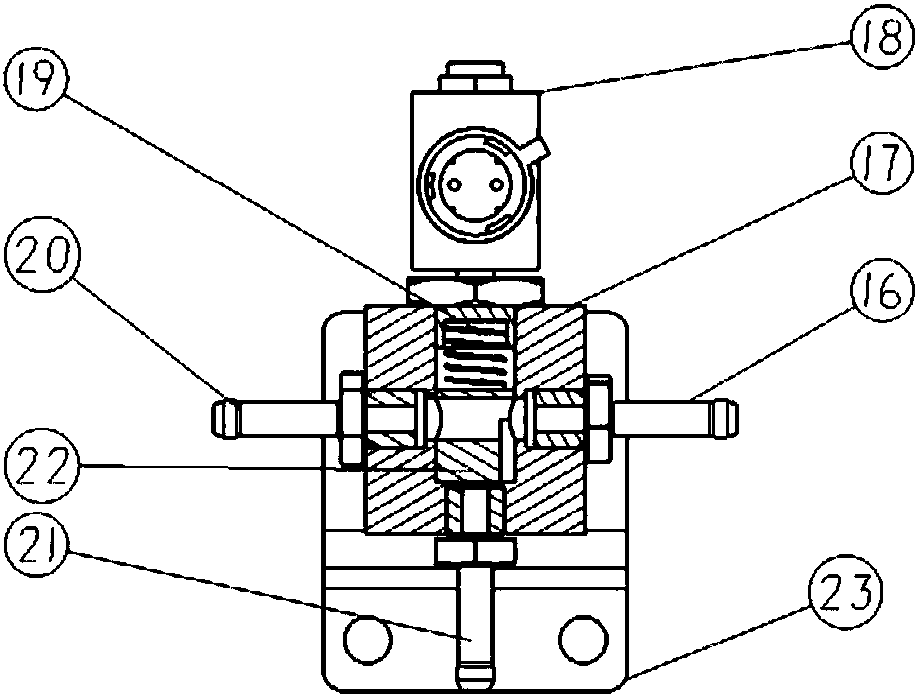

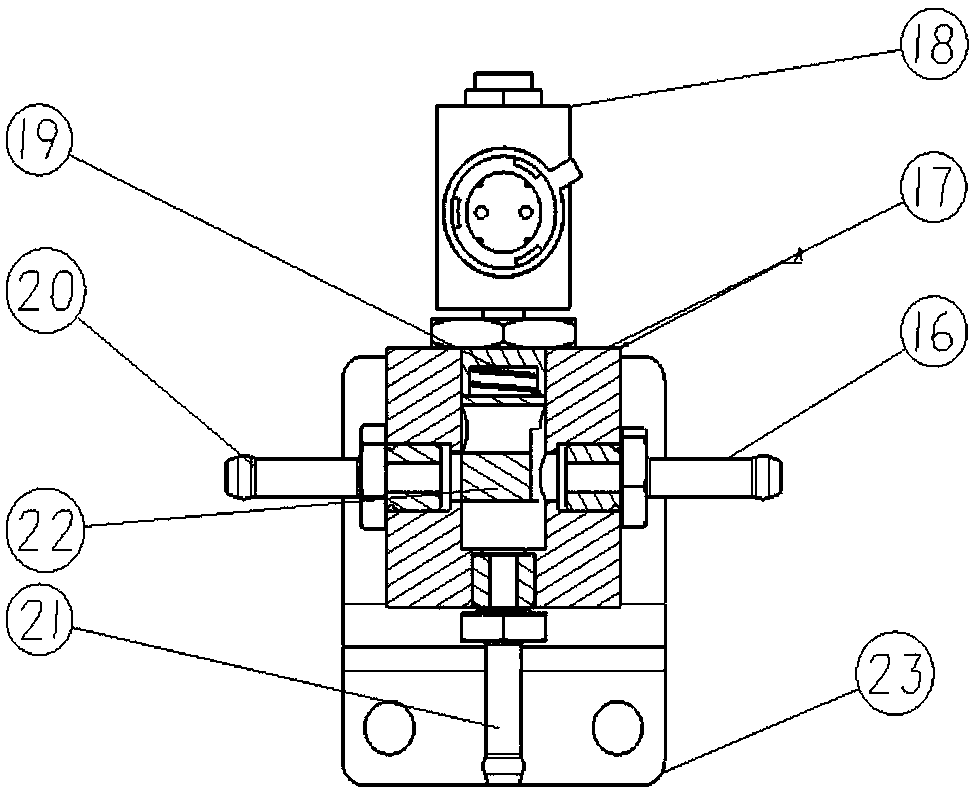

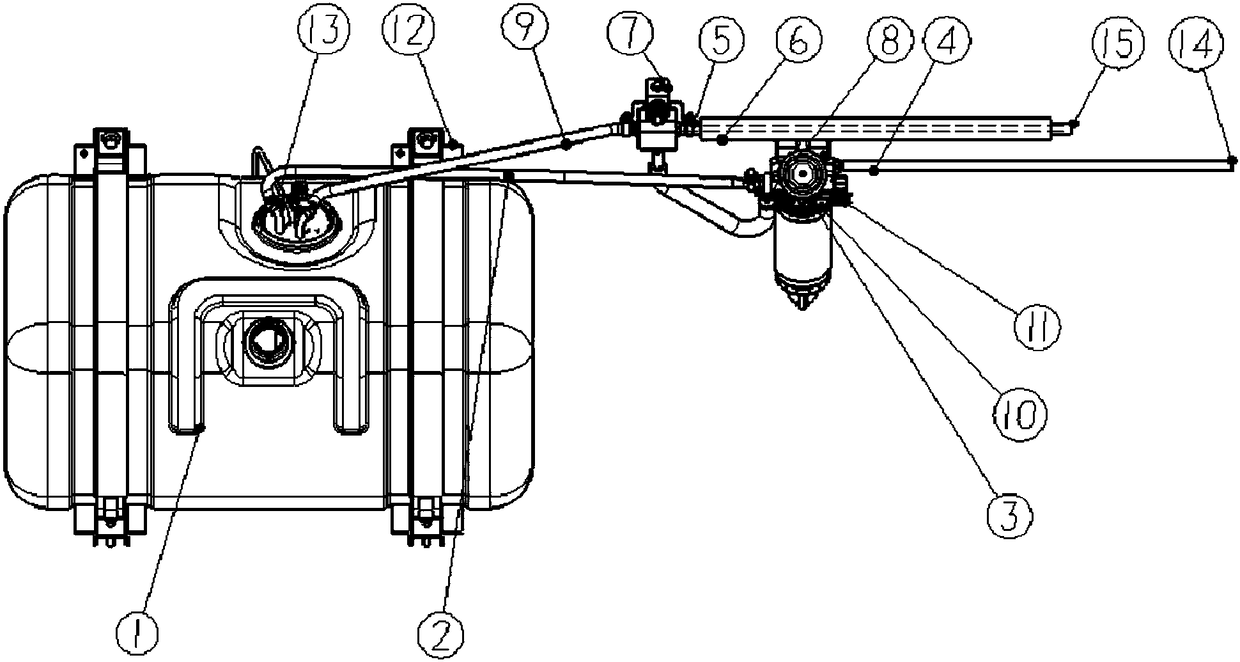

[0021] A low-pressure fuel supply system for diesel engines provided by the present invention has a structure such as Figure 1 to Figure 4 As shown, the part between the oil inlet of the 2 fuel tank and the 14 engine is the diesel engine oil inlet system, including the 1 fuel tank, which is fixed on the vehicle frame through the 12 fuel tank mounting bracket, and is used to store diesel oil; in the diesel engine oil inlet system, 3 fuel filters with hand oil pumps are set up, the 3 fuel filters with hand oil pumps are connected with 2 and 4 oil delivery hoses, and the joints are fastened with 13 steel band clamps; in the oil inlet system, 3 The fuel filter with hand oil pump is equipped with 10 disc fuel heaters and 11 fuel temperature sensors at the oil outlet of the filter, and has two oil inlet ports, which are respectively connected to 2 fuel tank oil outlet ports and 7 return ports. Oil three-way solenoid valve, 10 The power of the disc heater is usually set to 200~300W,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com