A leak-proof self-sealing valve

一种自密封、阀门的技术,应用在轴密封、控制阀、阀装置等方向,能够解决不能快速安装和拆卸、不能防外漏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

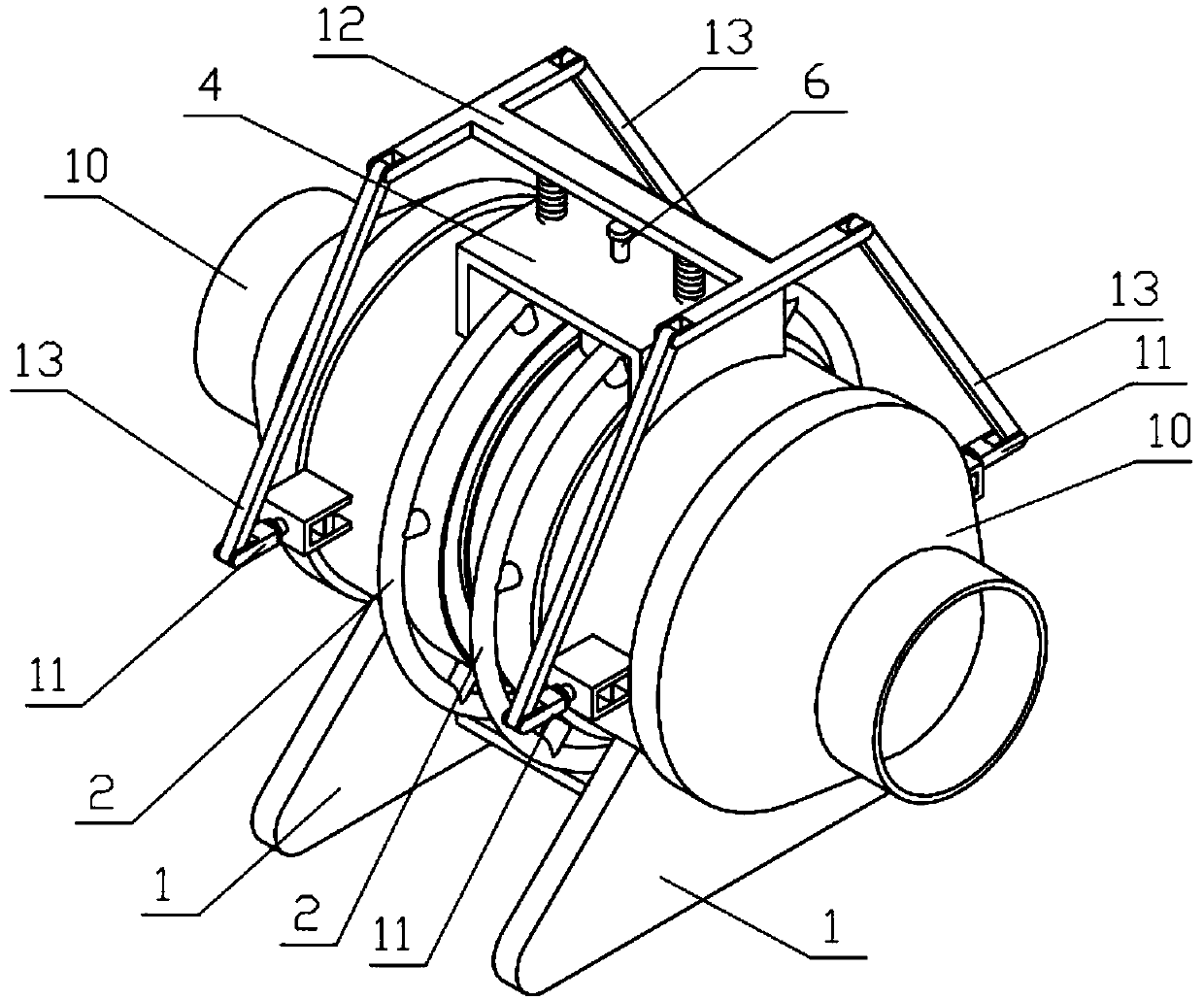

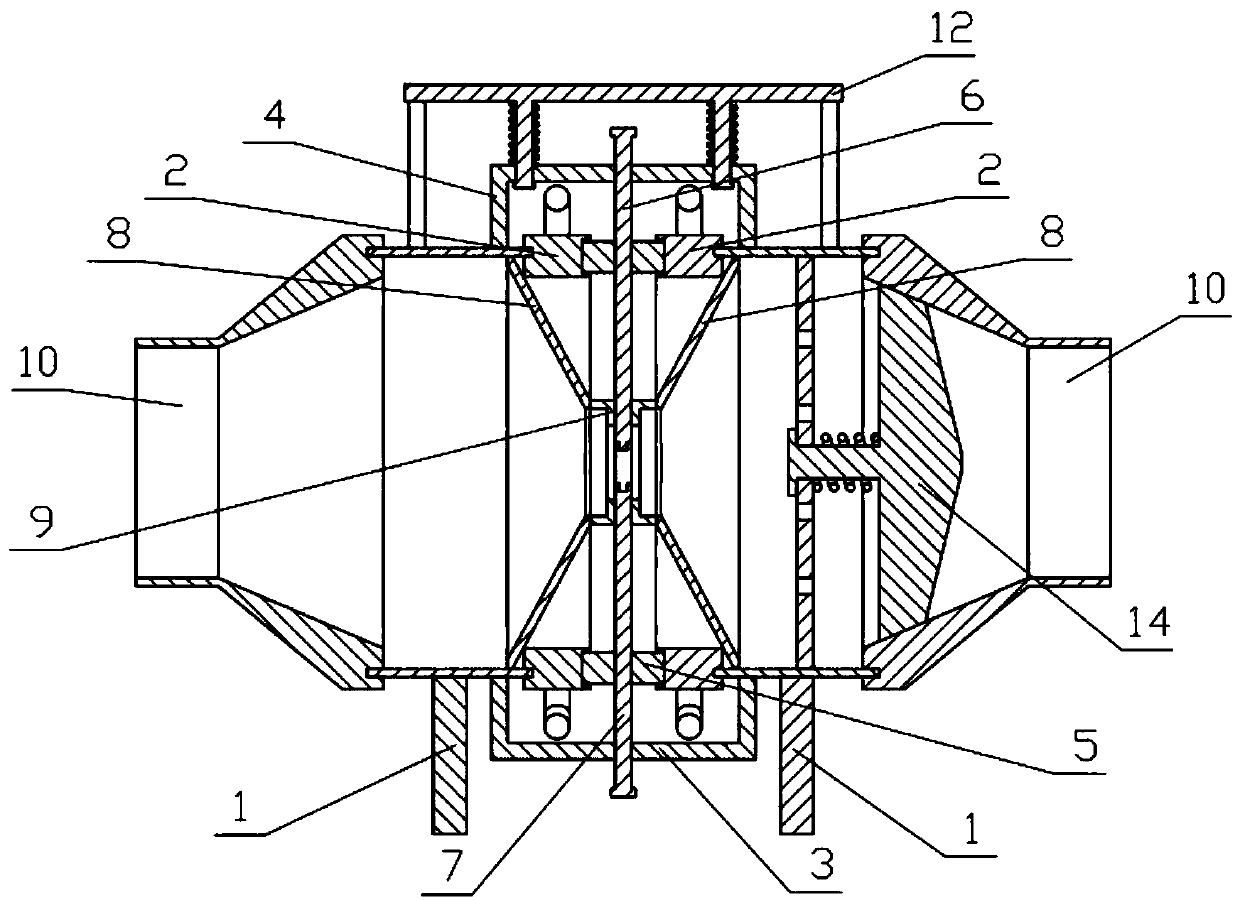

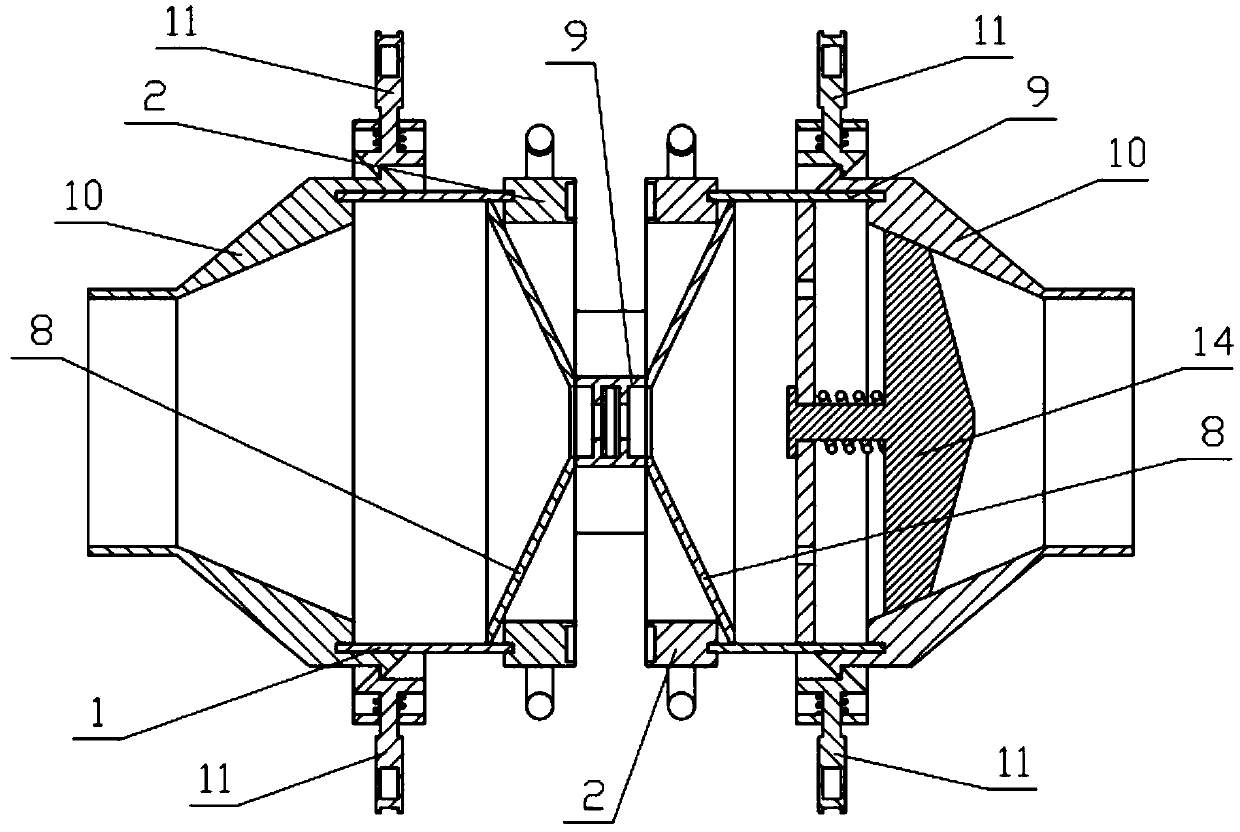

[0039] Combine below Figure 1-18 Describe this embodiment, a leakage-proof self-sealing valve, including a valve bracket 1, a rotating gear 2, a lower connecting plate 3, an upper connecting plate 4, a pinion 5, an upper closing plate 6, a lower closing plate 7, and a conical connection cylinder 8, connecting bracket 9, connecting cylinder 10, clamping mechanism 11, dismounting mechanism 12, connecting rod 13 and one-way mechanism 14, and the valve bracket 1 and the rotating gear 2 are all left and right symmetrically provided with two, two rotating gears 2 Rotate and connect to the inside of the two valve brackets 1 respectively, the left and right ends of the lower connecting plate 3 are respectively fixedly connected to the two valve brackets 1, and the left and right ends of the upper connecting plate 4 are respectively fixedly connected to the two valve brackets 1 , the upper connecting plate 4 is located at the upper end of the lower connecting plate 3, two pinion gears...

specific Embodiment approach 2

[0040] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain Embodiment 1, the valve bracket 1 includes a valve cylinder 1-1, a valve lower bracket 1-2, a valve side plate I1-3, a valve side plate II1-4 and a circular The through hole Ⅰ1-5, the valve lower bracket 1-2 is fixedly connected to the lower end of the valve cylinder 1-1, four valve side plates Ⅰ1-3 are symmetrically arranged, and the four valve side plates Ⅰ1-3 are respectively fixedly connected to the valve cylinder 1 The front and rear ends of -1, the two valve side plates Ⅰ1-3 at the front and rear ends are fixedly connected with the valve side plate Ⅱ1-4, and the two valve side plates Ⅱ1-4 are provided with circular through holes Ⅰ1-5 .

specific Embodiment approach 3

[0041] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the second embodiment, the rotating gear 2 includes a rotating gear body 2-1, a rotating column 2-2, a rotating handle 2-3, a gear groove 2-4 and an installation groove I2 -5, a sealing gasket is arranged in the installation groove I 2-5, and a plurality of rotating columns 2-2 are arranged, and the plurality of rotating columns 2-2 are evenly fixed and connected to the outer side of the rotating gear body 2-1 in the circumferential direction, and the rotating handle 2- 3. It is fixedly connected to the outer sides of a plurality of rotating columns 2-2. The gear groove 2-4 and the installation groove I 2-5 are respectively arranged at the right and left ends of the rotating gear body 2-1. The outer ends of each rotating gear body 2-1 are respectively connected to the inner sides of the two valve cylinders 1-1 through a mounting groove I 2-5; when in use, manually rotate the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com