Regenerative heating furnace with gas turnover pipelines

A heating furnace and regenerative technology, which is applied to lighting and heating equipment, furnaces, furnace types, etc. problem, to achieve the effect of good preheating effect, good sealing performance and not easy to be damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

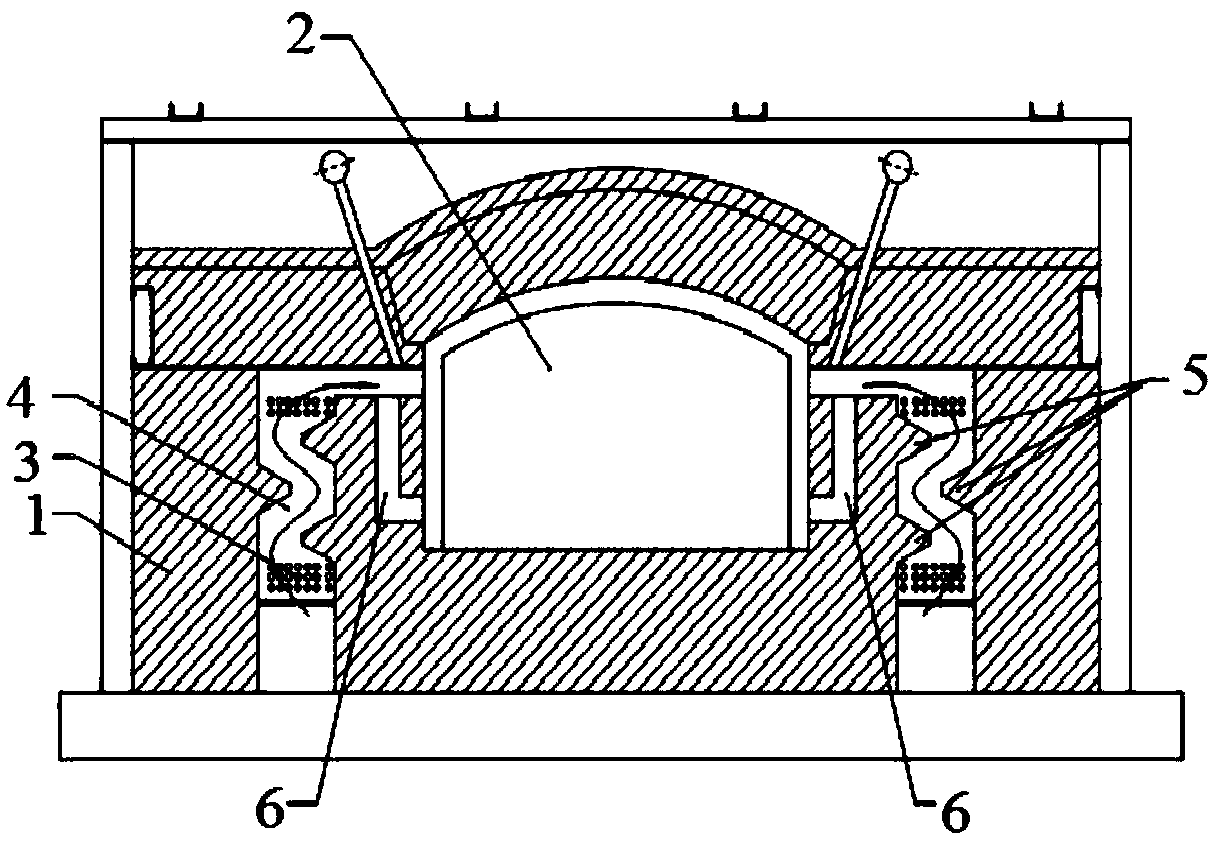

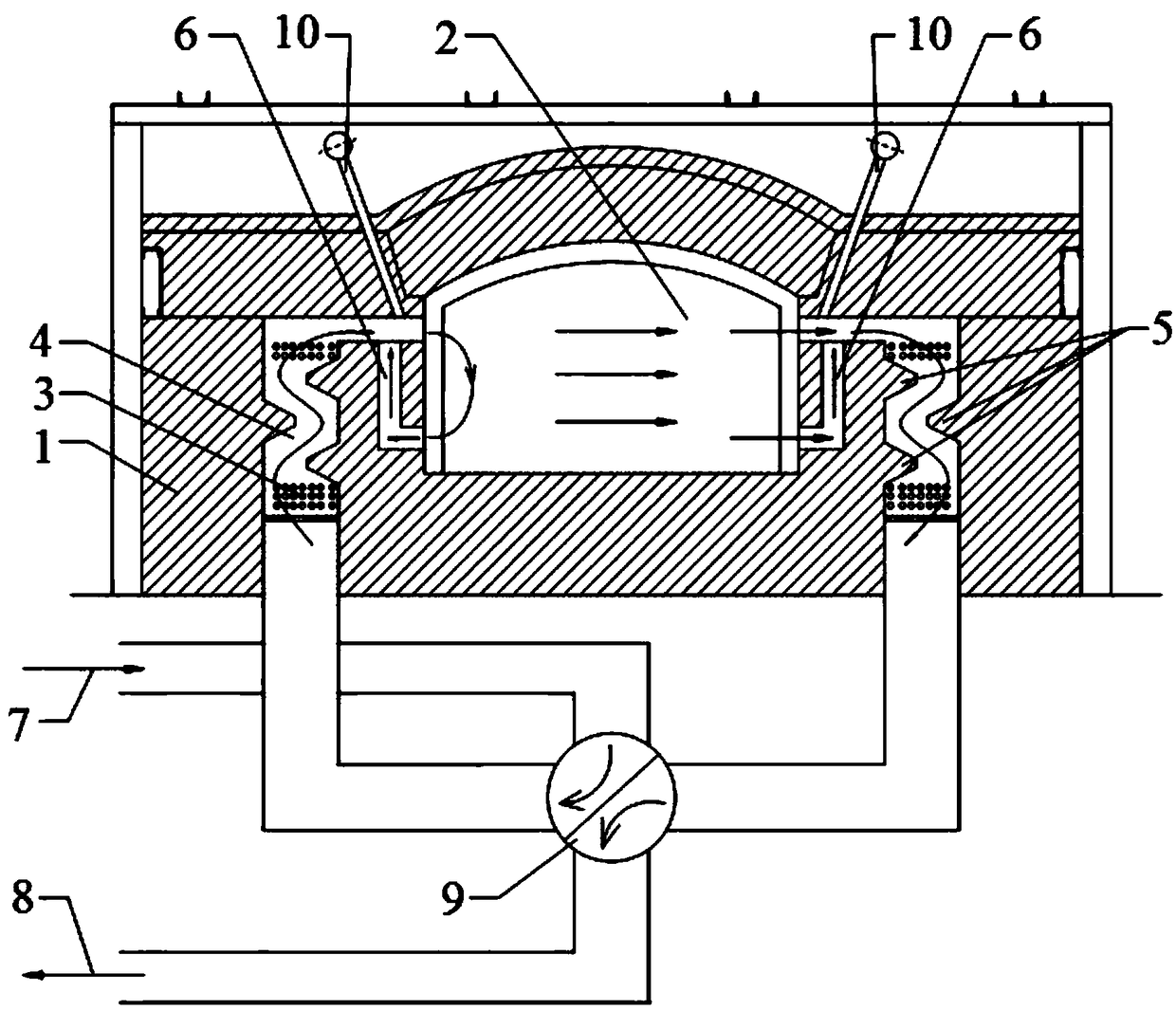

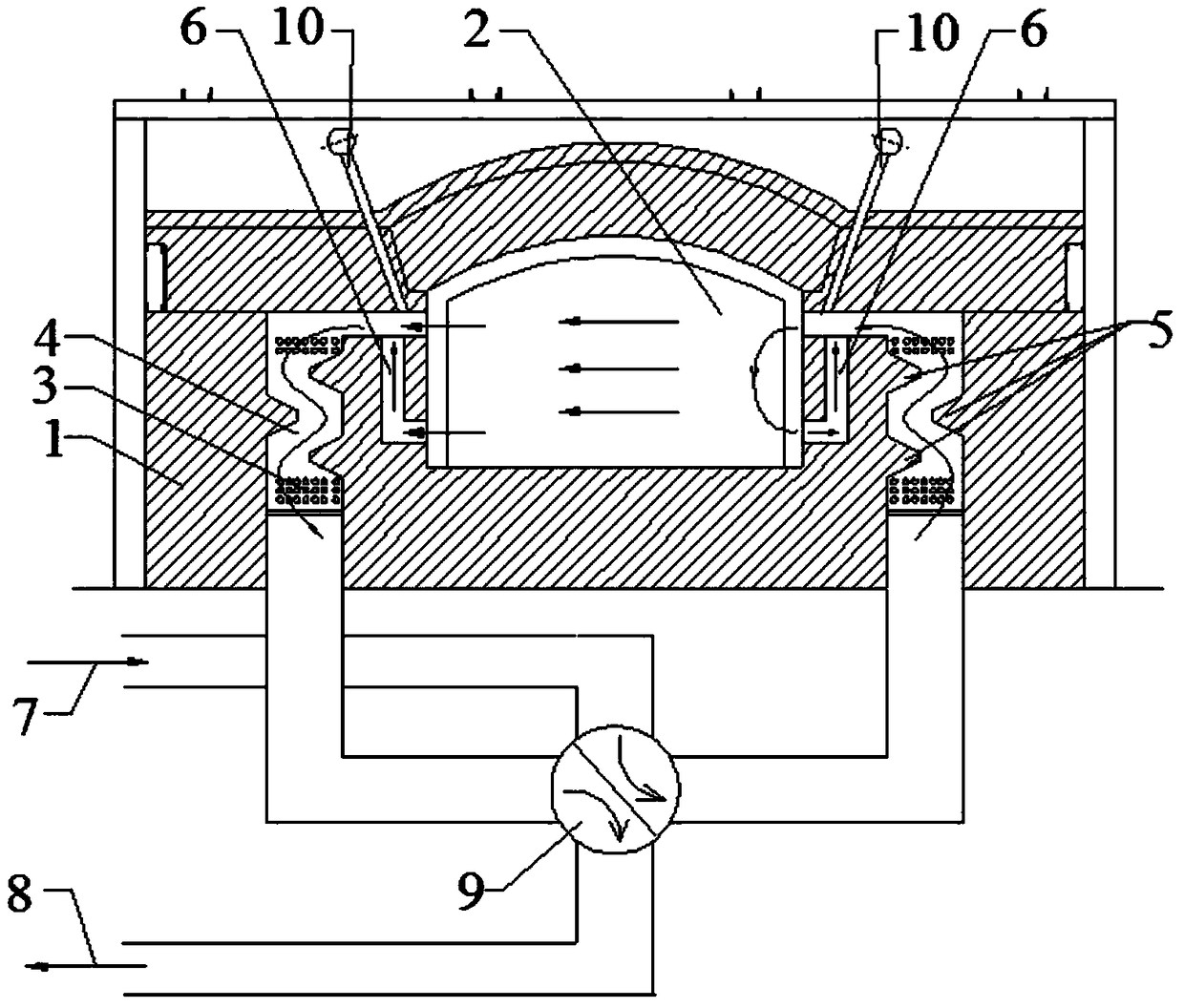

[0021] Such as figure 1 , 2 As shown in 6-8, a regenerative heating furnace with gas circulation pipelines includes a furnace body 1, a furnace chamber 2, a furnace door, and a furnace door sealing structure. The furnace body 1 is provided with a pair of heat storage chambers 4 With a pair of gas circulation pipes 6, the gas circulation pipe 6 is inside and the heat storage tank 4 is outside. One end of the gas circulation pipe 6 communicates with the heat storage compartment 4, and the other end communicates with the lower part of the furnace 2. The inner wall of the heat storage compartment 4 is from above A barrier device 5 is arranged in the lower interval, and the heat storage compartment 4 is filled with a heat storage 3.

[0022] The furnace door sealing structure is arranged at the furnace door of the furnace body 1. The furnace door includes a furnace door cover 12.3 and a heat-resistant filler layer 12.2 located inside the furnace door cover 12.3. The heating furnace inc...

Embodiment 2

[0025] Such as Figure 1-3 As shown in 6-8, a regenerative heating furnace with gas circulation pipelines includes a furnace body 1, a furnace chamber 2, a furnace door, and a furnace door sealing structure. The furnace body 1 is provided with a pair of heat storage chambers 4 With a pair of gas circulation pipes 6, the gas circulation pipe 6 is inside and the heat storage tank 4 is outside. One end of the gas circulation pipe 6 communicates with the heat storage compartment 4, and the other end communicates with the lower part of the furnace 2. The inner wall of the heat storage compartment 4 is from above A barrier device 5 is arranged in the lower interval, and the heat storage compartment 4 is filled with a heat storage 3.

[0026] The furnace door sealing structure is arranged at the furnace door of the furnace body 1. The furnace door includes a furnace door cover 12.3 and a heat-resistant filler layer 12.2 located inside the furnace door cover 12.3. The heating furnace incl...

Embodiment 3

[0029] Such as Figure 1-8 As shown, a regenerative heating furnace with a gas circulation pipeline includes a furnace body 1, a furnace chamber 2, a furnace door, and a furnace door sealing structure. The furnace body 1 is provided with a pair of heat storage chambers 4 and a pair of gas Circulation pipe 6, gas circulation pipe 6 is inside, heat storage compartment 4 is outside. One end of gas circulation pipe 6 communicates with heat storage compartment 4, and the other end communicates with the lower part of furnace 2, and the inner wall of heat storage compartment 4 is spaced from top to bottom. There is a barrier device 5, and the heat storage chamber 4 is filled with a heat storage 3.

[0030] The furnace door includes a furnace door support frame 11.1, heat-resistant bricks 11.2, a limit device 11.3, a tie rod 11.4, a gas cabin 11.5, a connecting block 11.6, a bracket 11.8 and a connecting groove 11.9, the cylinder body of the gas cabin 11.5, and a bracket 11.8 One end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com