An optimized power tower with single side air intake

A technology for mechanical towers and fans, which is applied to water shower coolers, lighting and heating equipment, heat exchanger types, etc. The tower inlet air balance configuration and other issues can reduce coal consumption or steam consumption, increase the width, and improve the heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

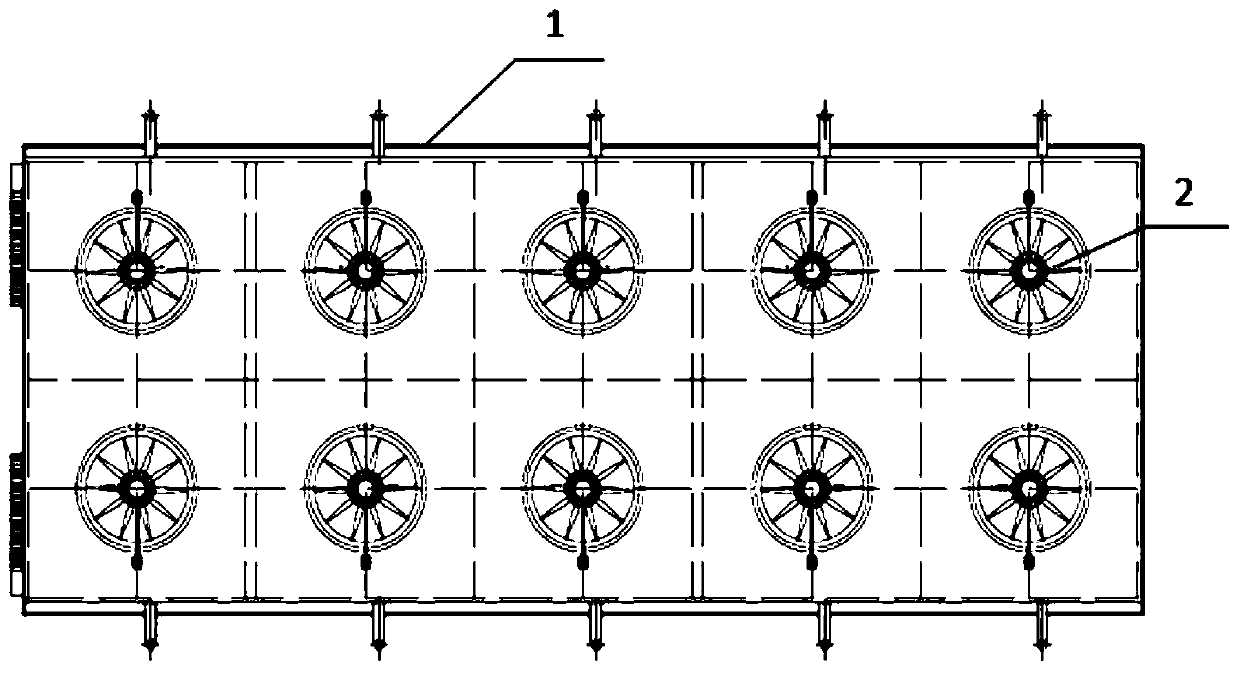

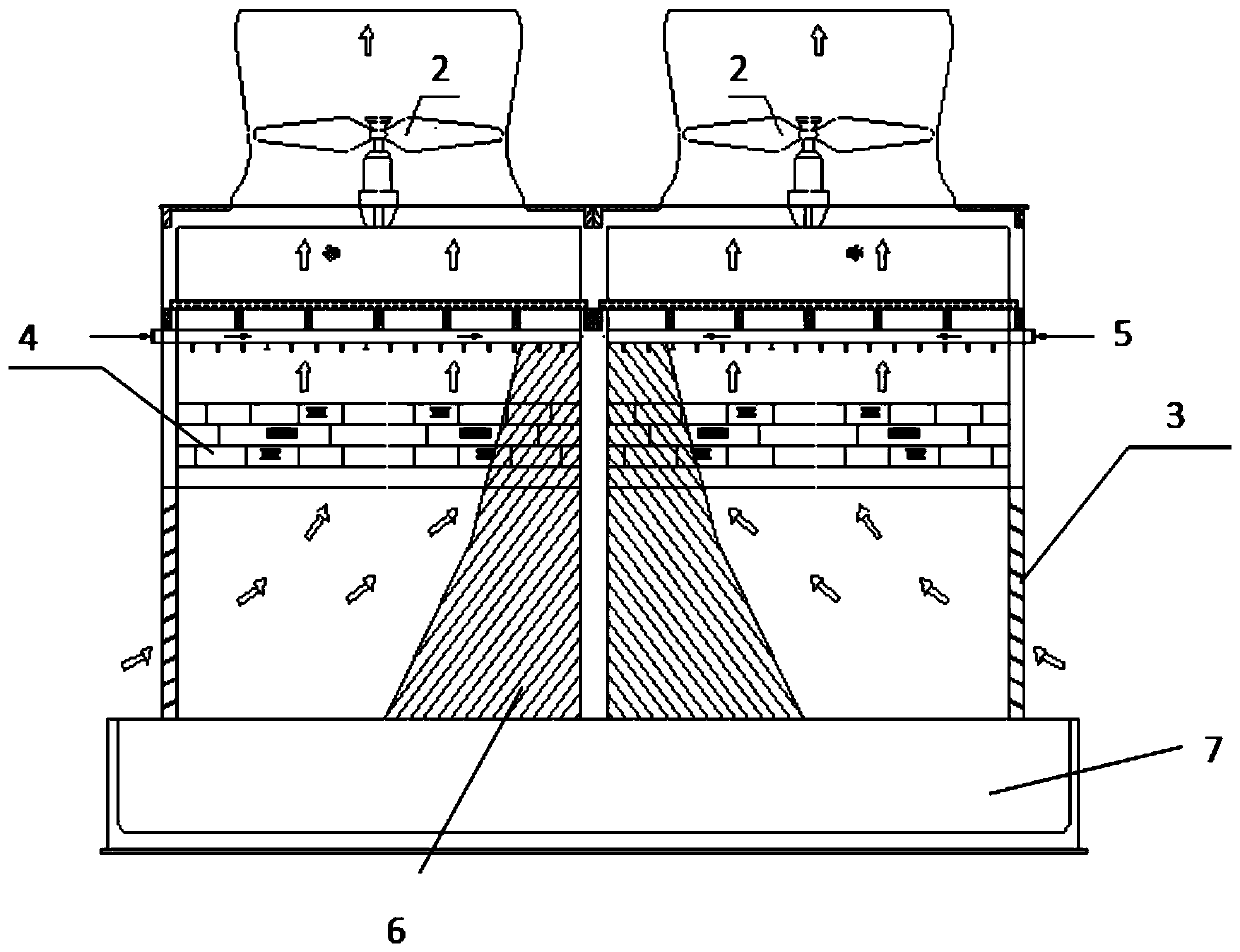

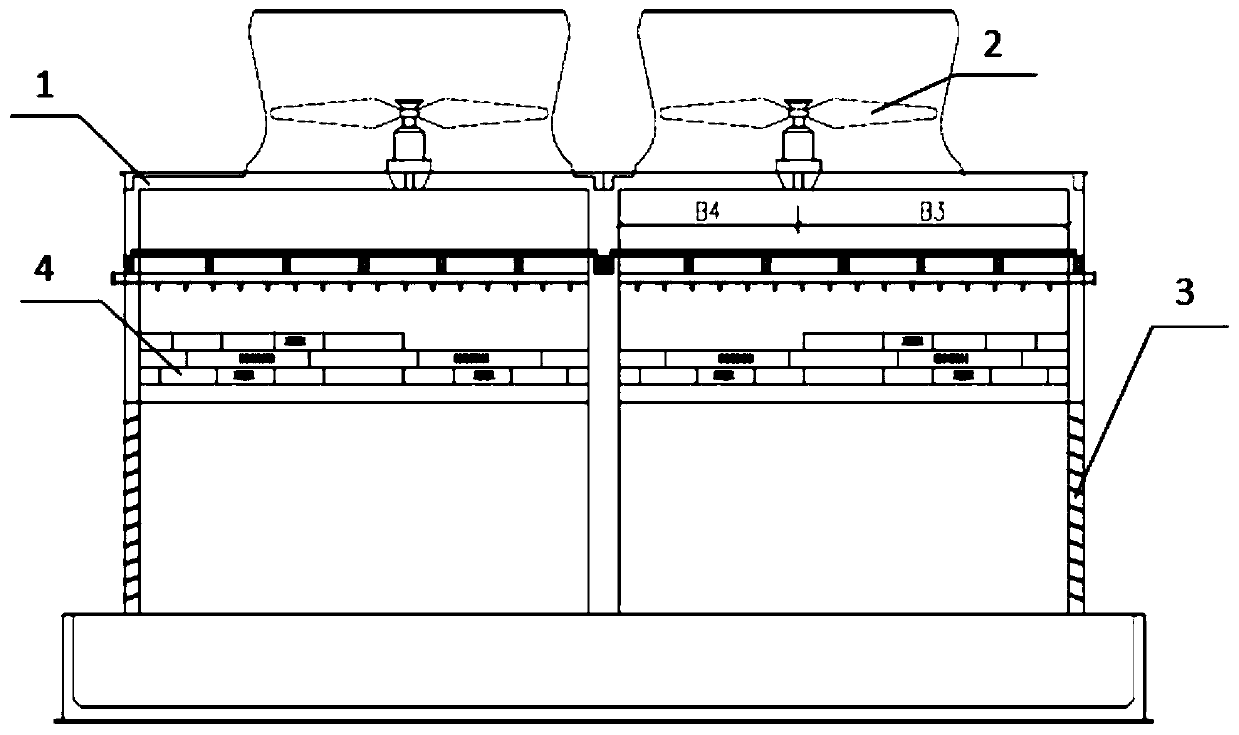

[0024] Such as image 3 As shown, the embodiment of the present invention provides an optimized single-side wind inlet power tower, the power tower includes a tower body 1 , a fan 2 and packing 4 , and the tower body is provided with an air inlet 3 . Because the wind enters the power tower from one side, after the wind enters the power tower from the air inlet 3, it will form a windward side and a leeward side in the tower, so the filler 4 can be divided into a windward side filler and a leeward side filler.

[0025] The fan 2 of the conventional power tower is arranged at the very center of the tower, that is, the distance from the centerline of the fan 2 to the inner walls on both sides of the power tower is equal. With the arrangement of the fan 2 in this form, when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com