Patents

Literature

30results about How to "Lower the cooling water temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

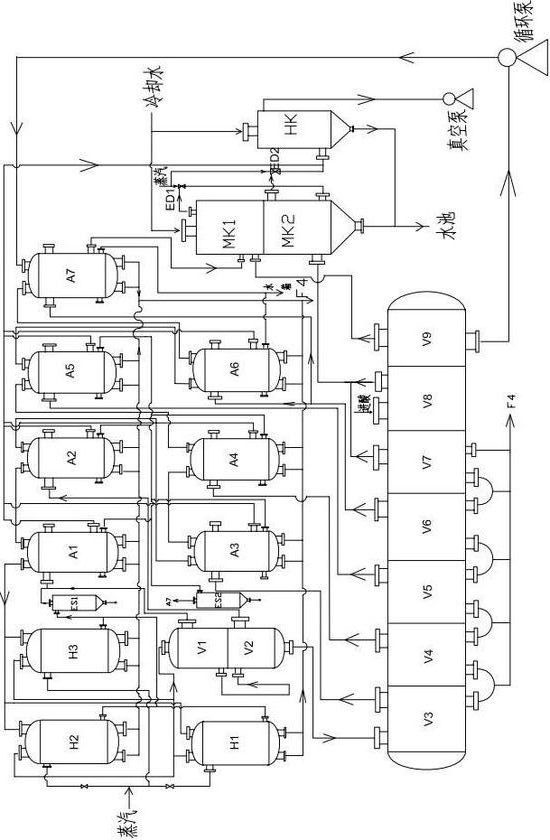

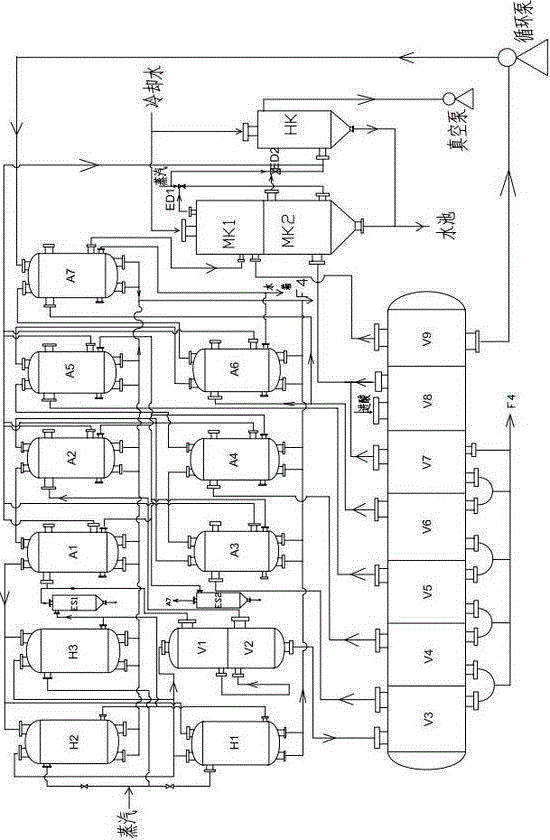

Multistage evaporating process in viscose production

ActiveCN102100973ATake advantage ofImprove evaporation efficiencyEvaporationWater useProcess engineering

The invention relates to a multistage evaporating process in viscose production, which comprises the steps of acid bath heating, acid bath evaporating, secondary steam recycling and exhausting, condensed water discharging, incoagulable gas exhausting and the like. Aiming at the prior art, equipment and a process route are re-designed, secondary steam is recycled, the heat which is not utilized inthe prior art is fully utilized, so that the purpose of improving the yield is achieved, the zero emission of evaporating water is realized, and a large quantity of sewage treatment cost and clear water supply and discharge costs are saved.

Owner:CHENGDU GRACE FIBER +1

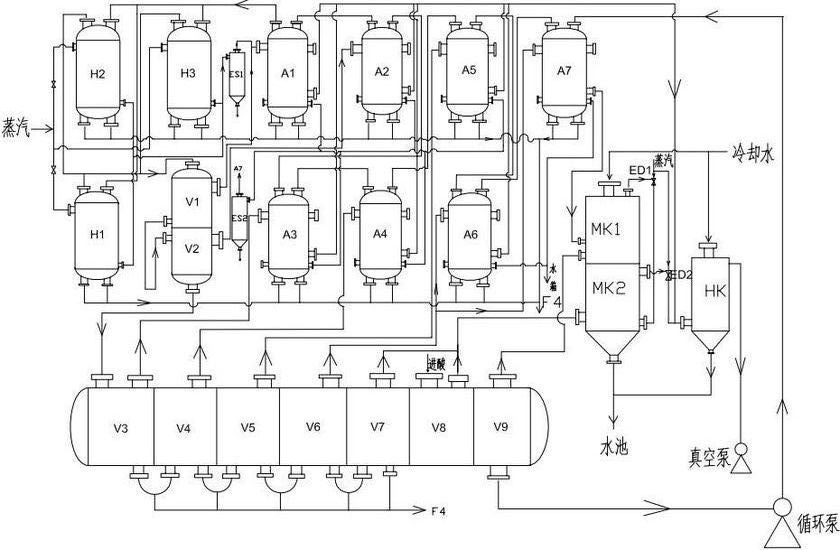

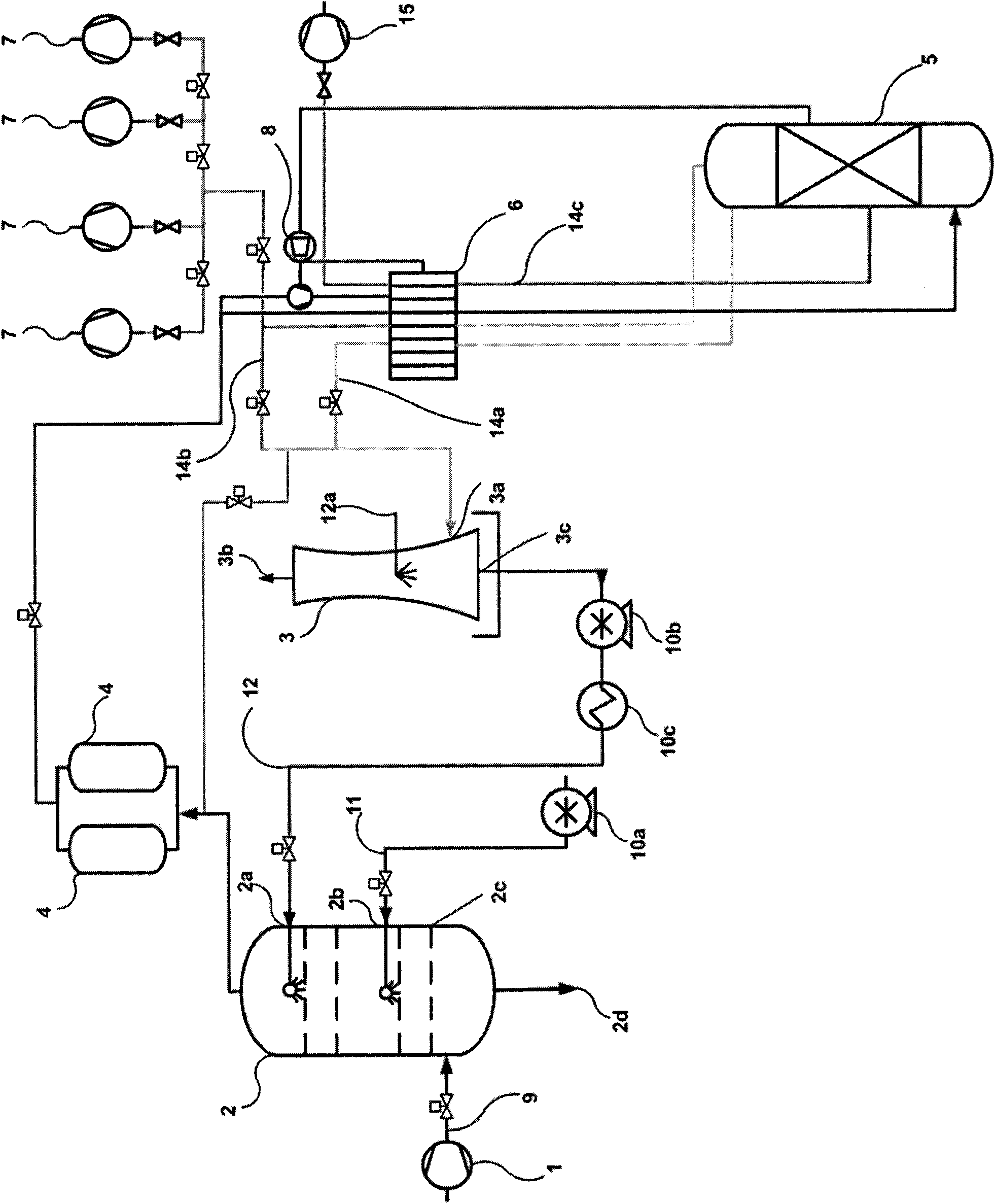

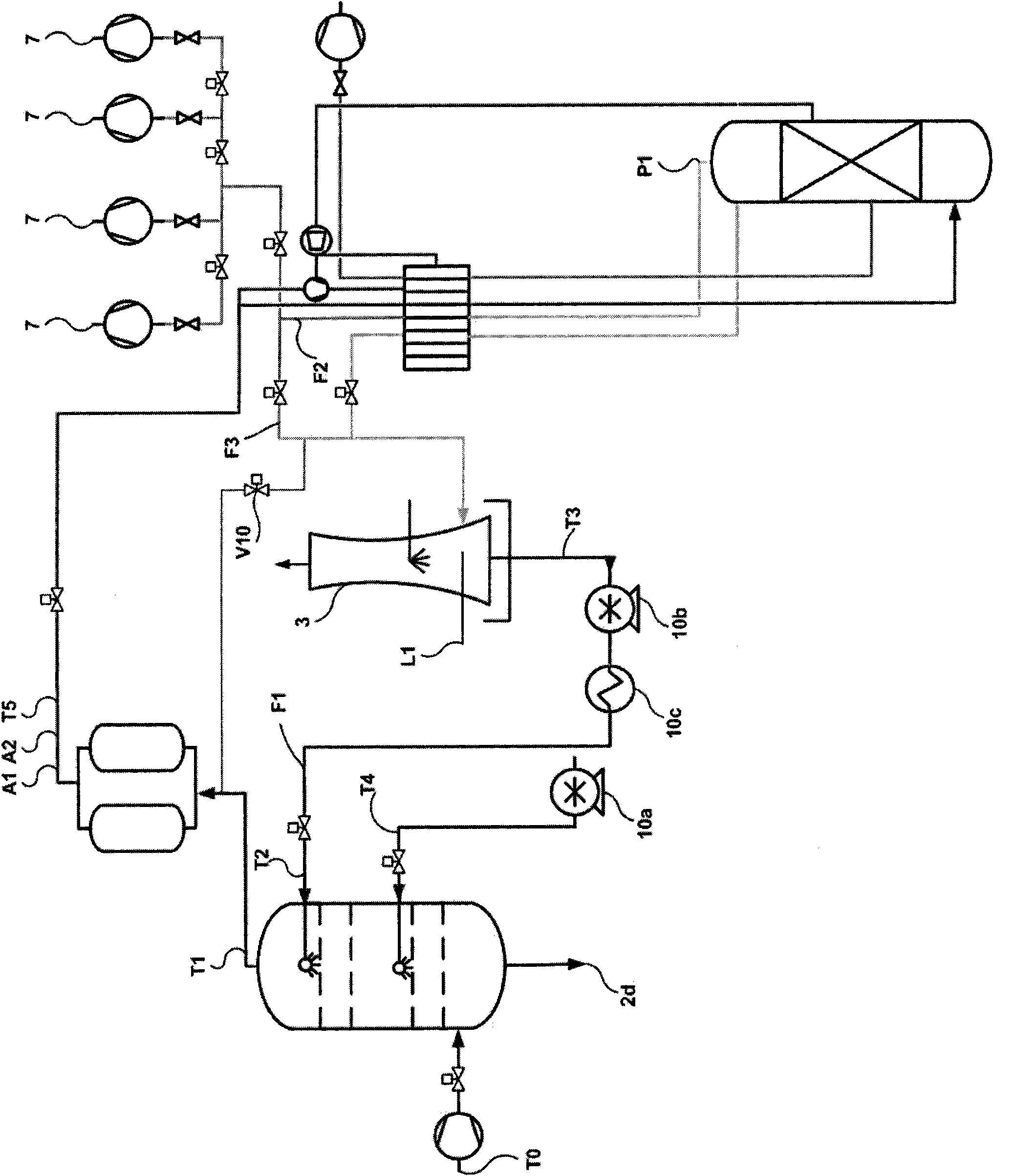

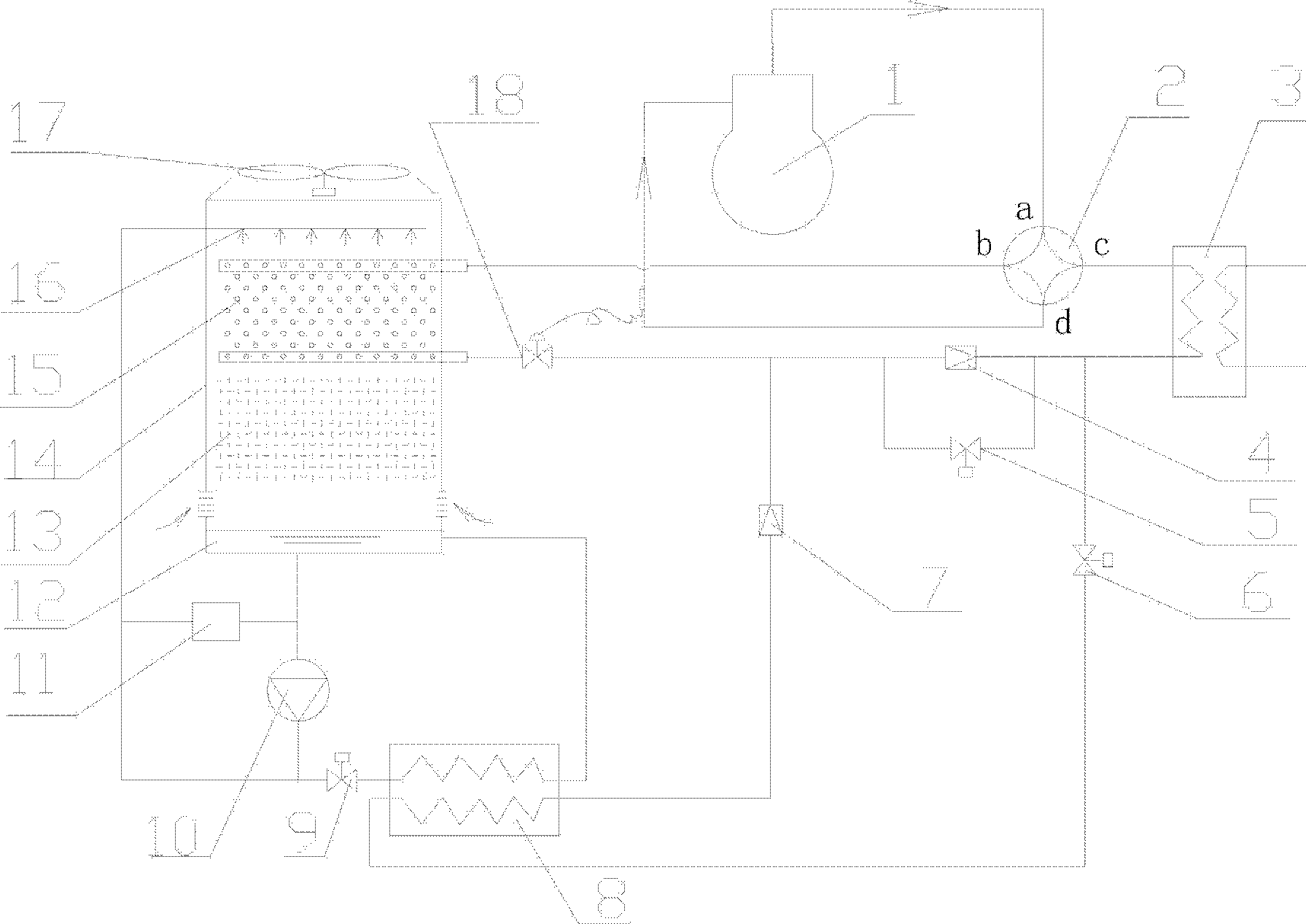

Gradient utilization system of coal chemical industry process steam condensate energy

PendingCN111595172AImprove efficiencyLow running costChemical industryCompression machinesProcess systemsThermodynamics

The invention creatively provides a gradient utilization system of coal chemical industry process steam condensate energy. The gradient utilization system of the coal chemical industry process steam condensate energy comprises a closed type condensate recycling unit, a jet type refrigerating unit, a hot water heat exchange unit, a process refrigerating unit and a cold water heat exchange unit. Theclosed type condensate recycling unit is connected with the jet type refrigerating unit. The jet type refrigerating unit is connected with the hot water heat exchange unit and the heat exchange refrigerating unit which are arranged in parallel. The heat exchange refrigerating unit comprises the cold water heat exchange unit and the process refrigerating unit which are sequentially connected. Thegradient utilization system of the coal chemical industry process steam condensate energy can further utilize low-order waste heat, improves the efficiency of the process refrigerating unit, lowers the operation cost of a process system, saves energy and is environmentally friendly.

Owner:CHINA TIANCHEN ENG

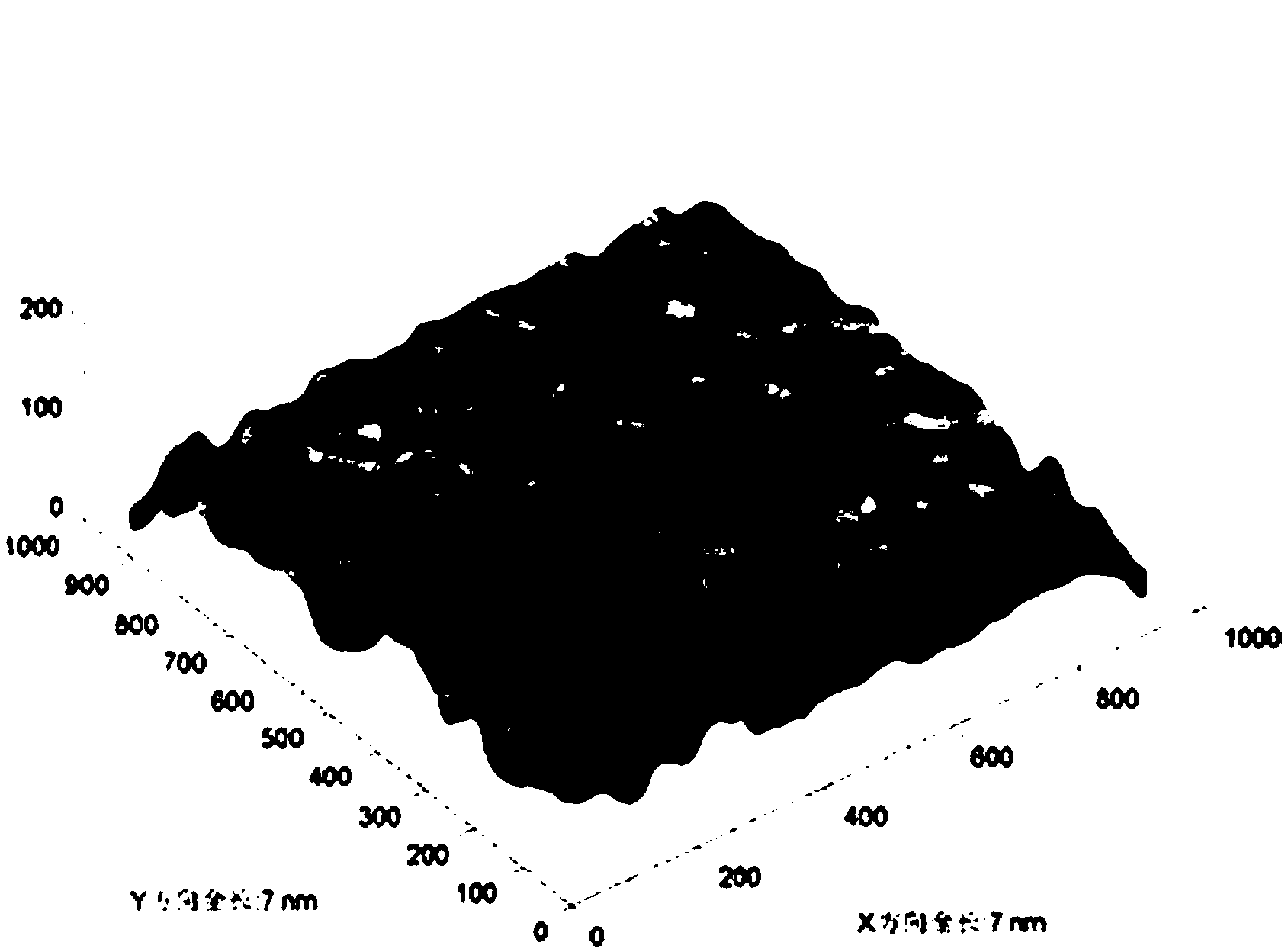

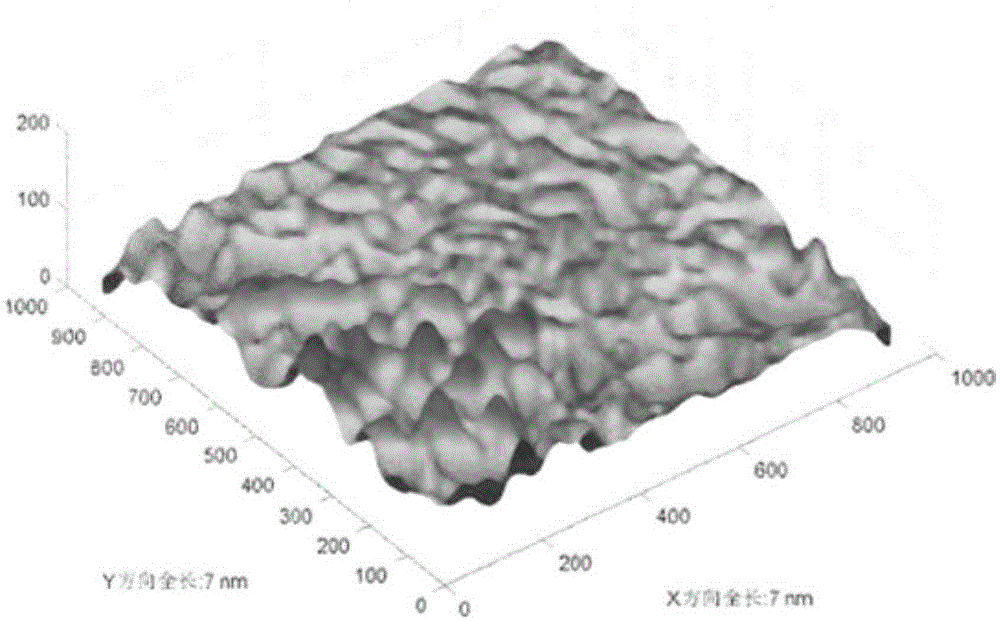

Nano-diamond automatic repair liquid for reciprocating piston engine

The invention discloses a nano-diamond automatic repair liquid for a reciprocating piston engine. The liquid is characterized by being prepared by the following steps: (1) adding a nano-diamond into a dispersant OP-10, stirring for over 20 minutes, then standing, and after bubbles fully disappear and black precipitates appear at the bottom, pouring out a supernate, wherein the nano-diamond is a spherical particle, the grain size of which is 2-4n, and the addition proportion of OP-10 and the nano-diamond is 0.8-1.2mg of nano-diamond per L of OP-10; and (2) adding the supernate into lubricating oil, and stirring and mixing to obtain the automatic repair liquid, wherein the weight ratio of the supernate and the lubricating oil in percentage by weight is (10-30%):(90-70%). The nano-diamond in the automatic repair liquid is good in dispersing effect and stable and can be placed for a long time. The repair liquid is simple in formula, low in cost and simple in preparation method.

Owner:CHONGQING HAILIYUN TECH

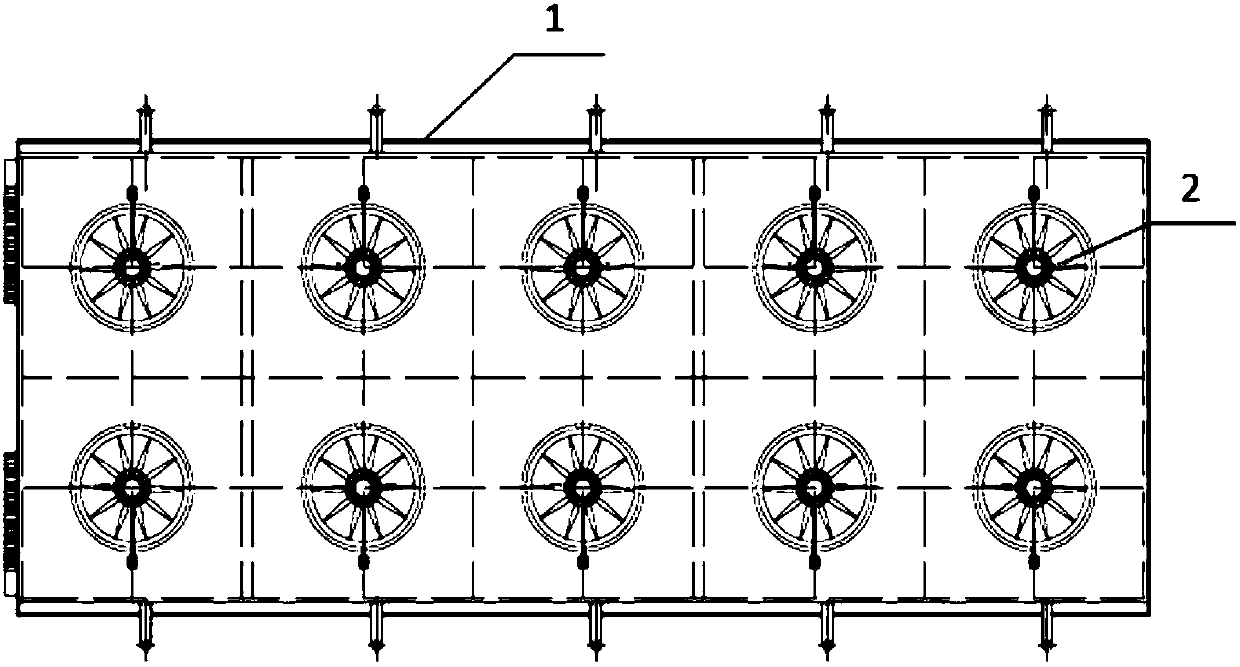

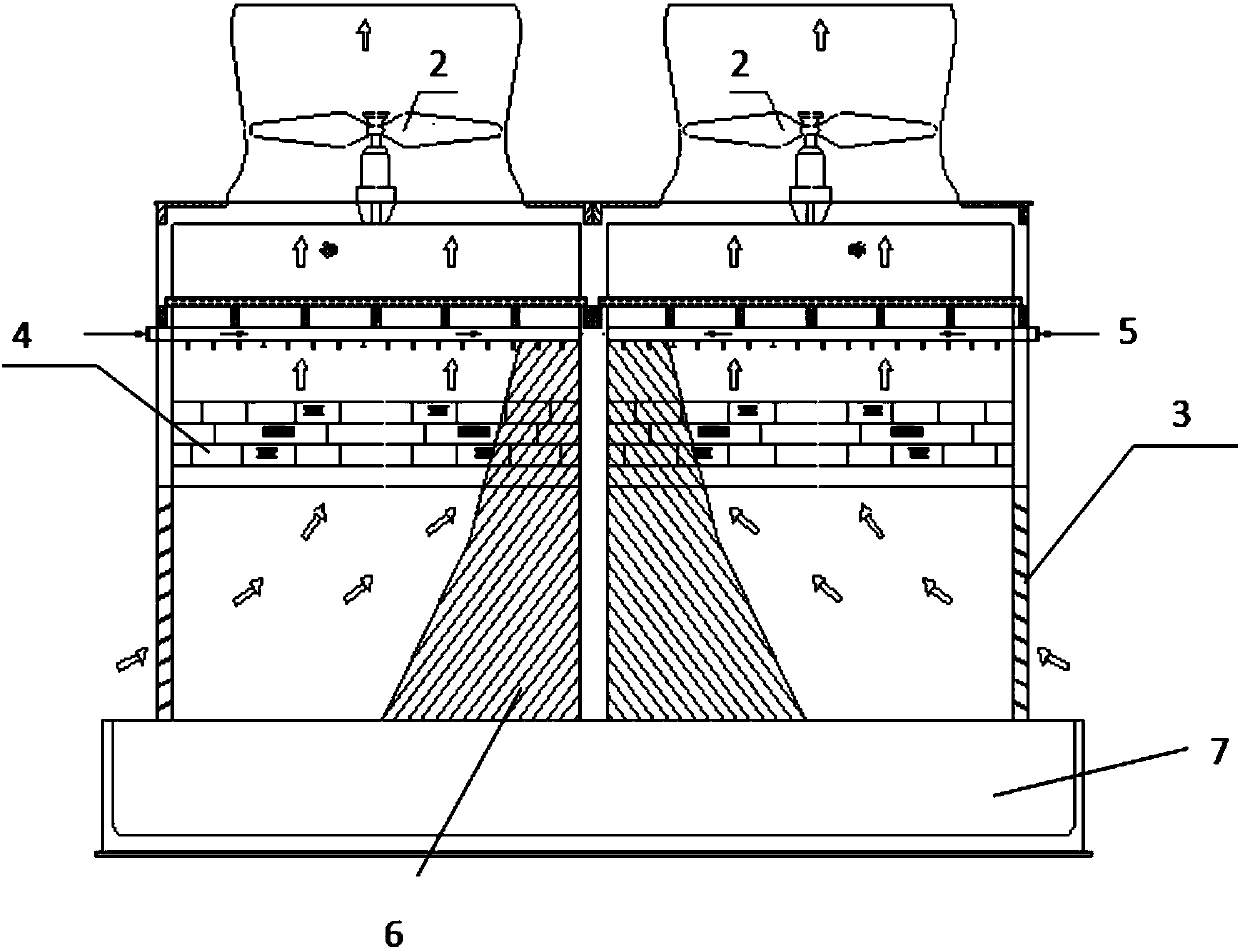

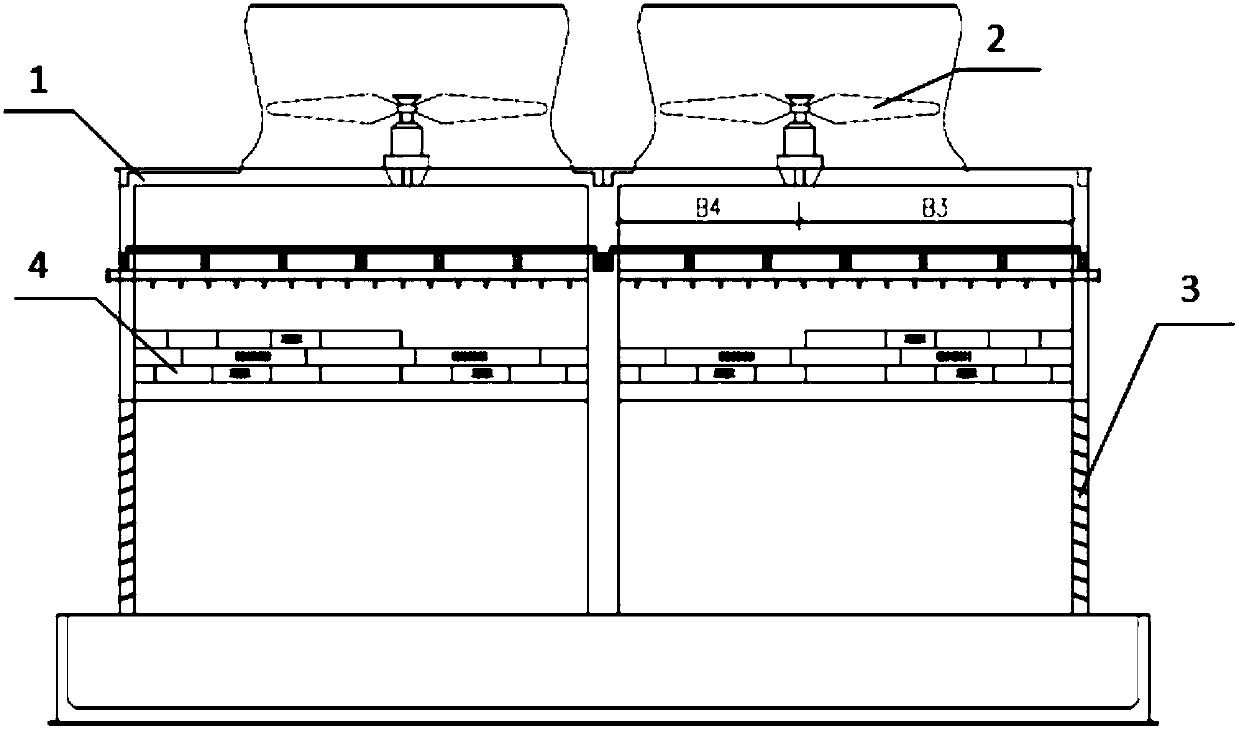

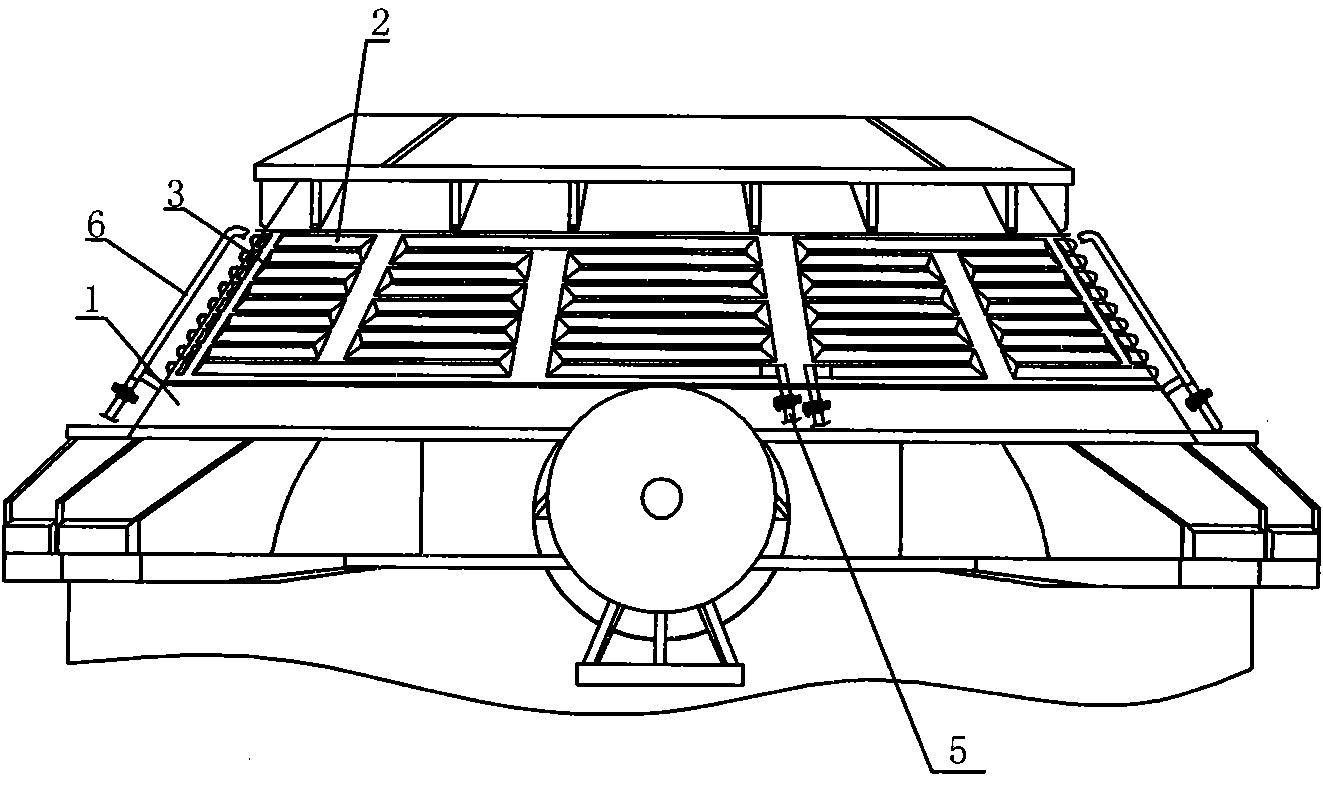

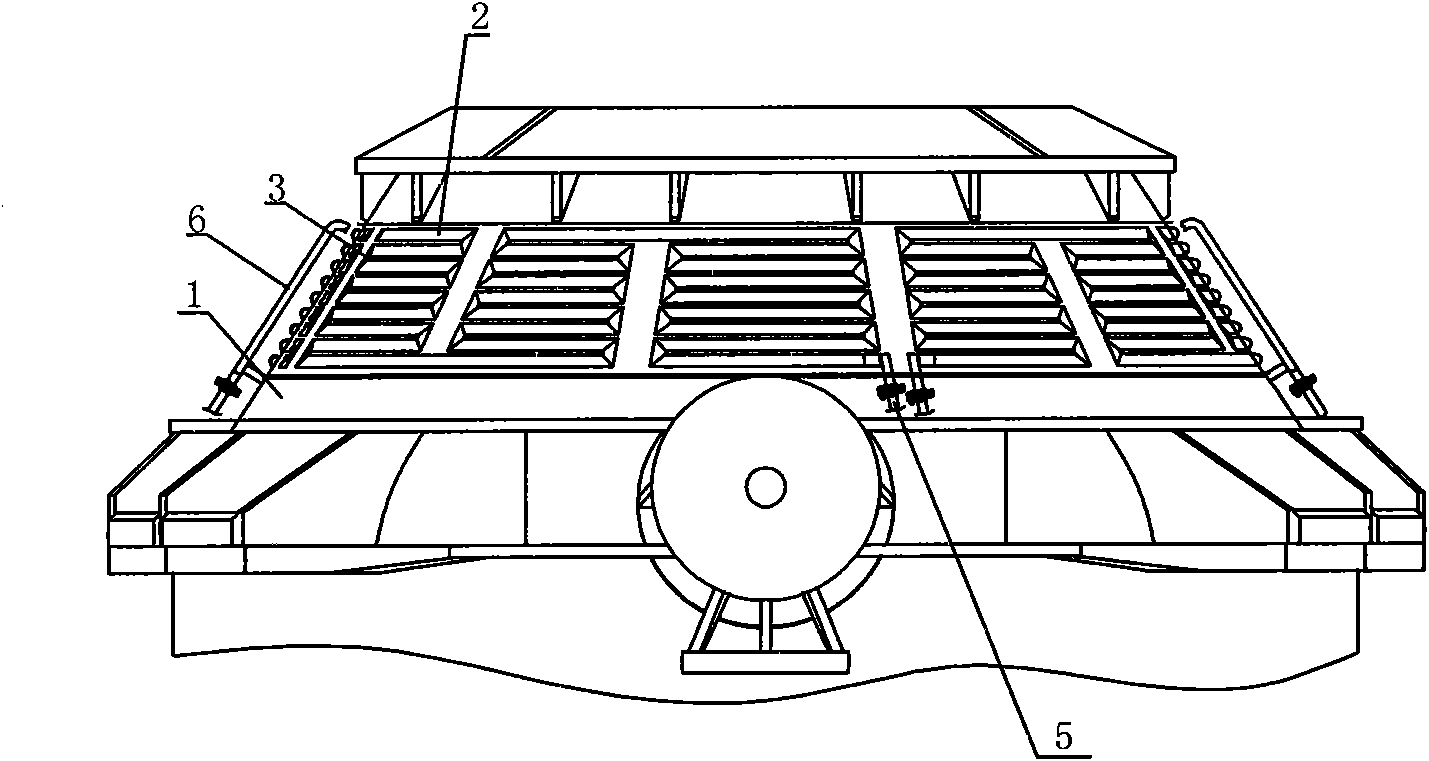

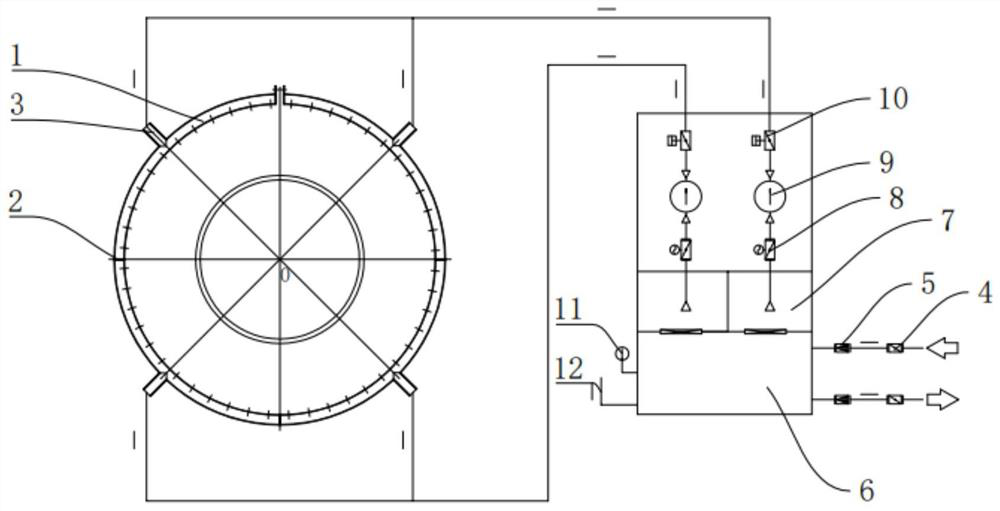

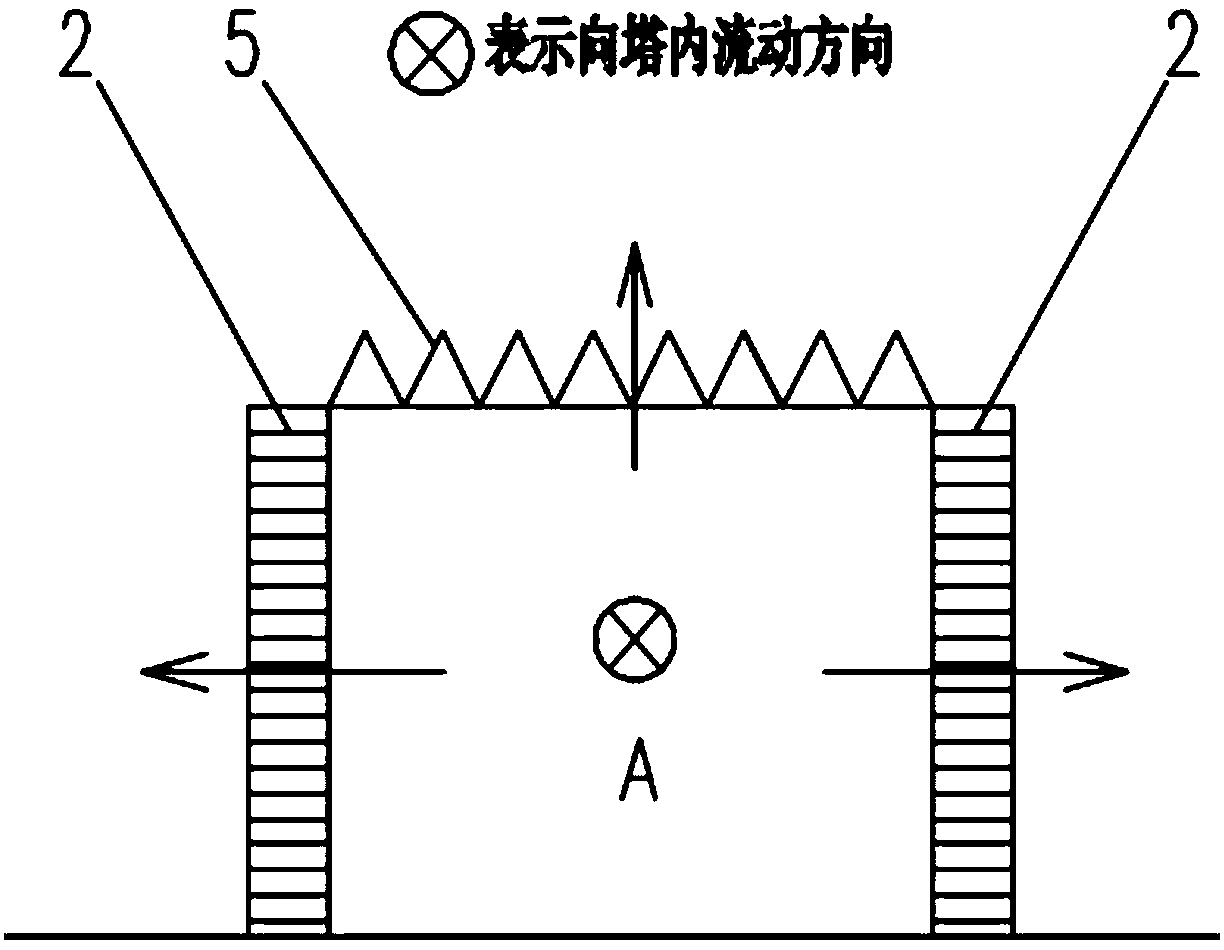

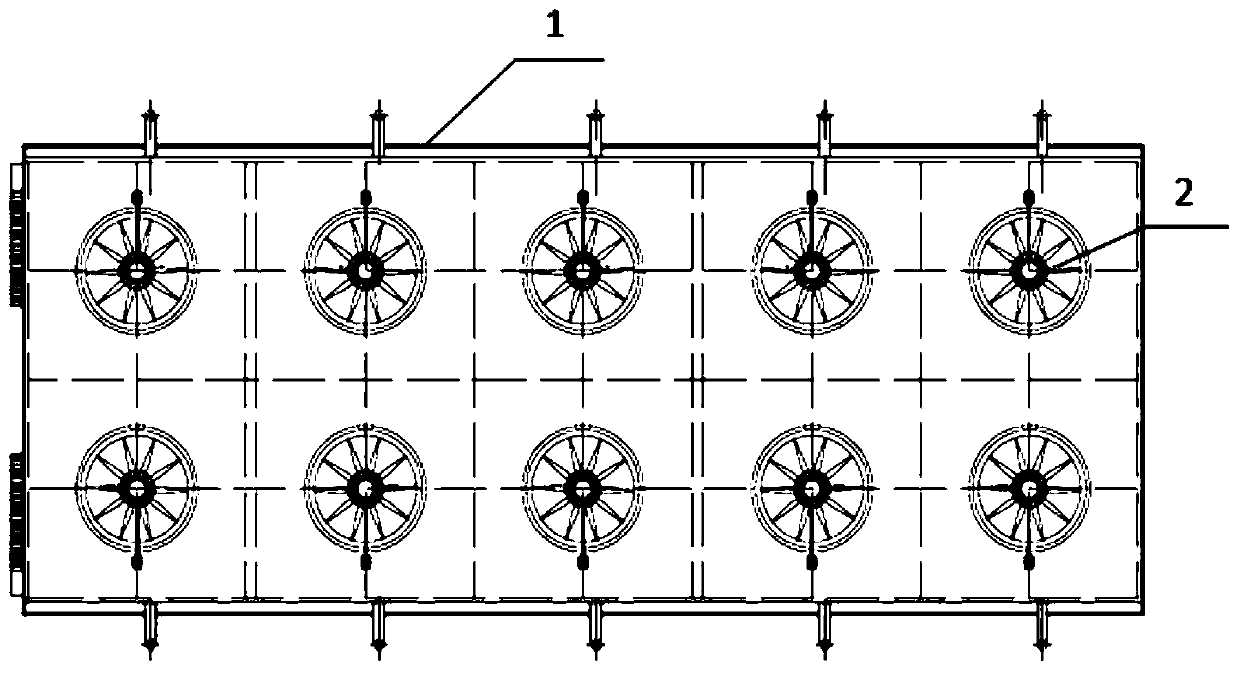

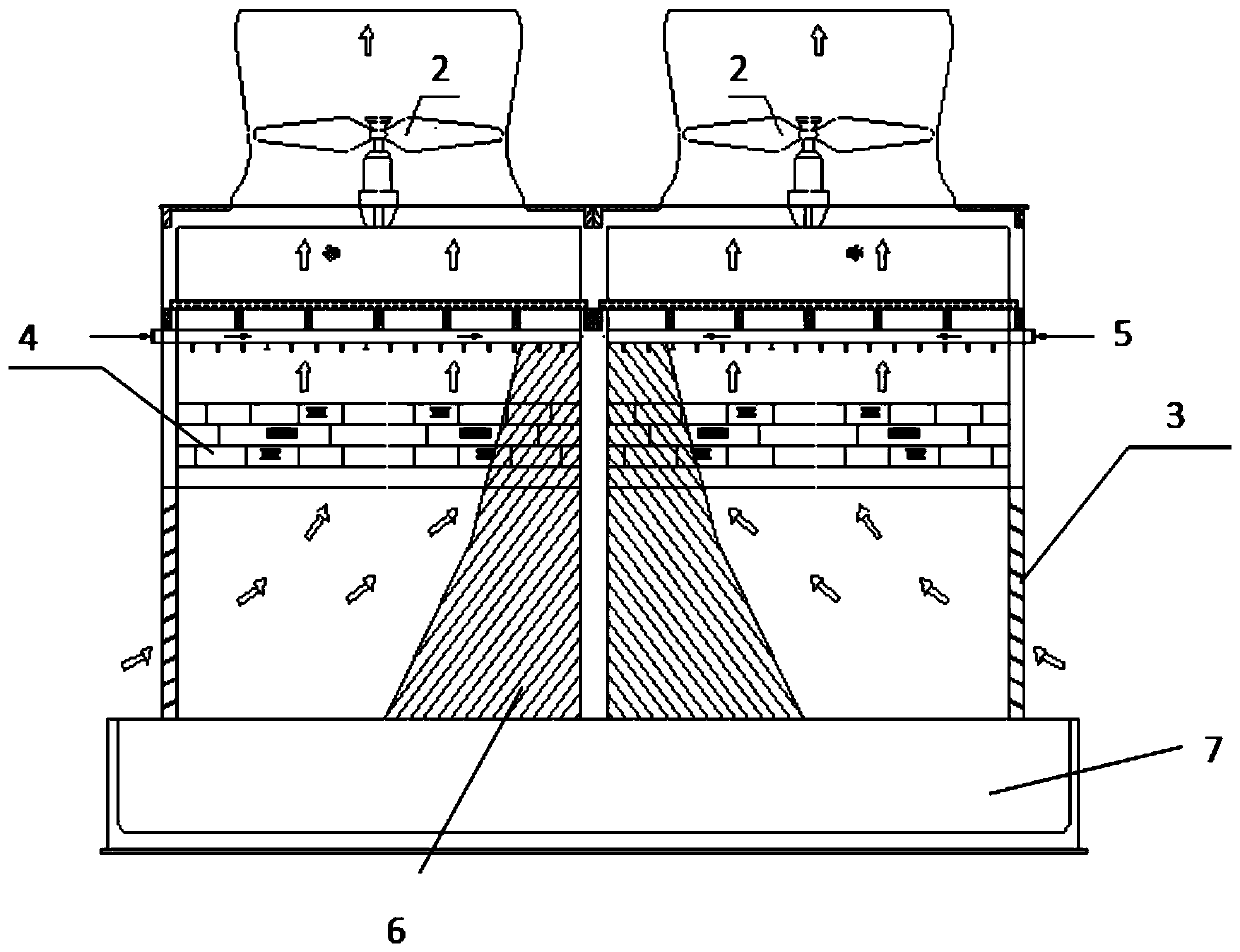

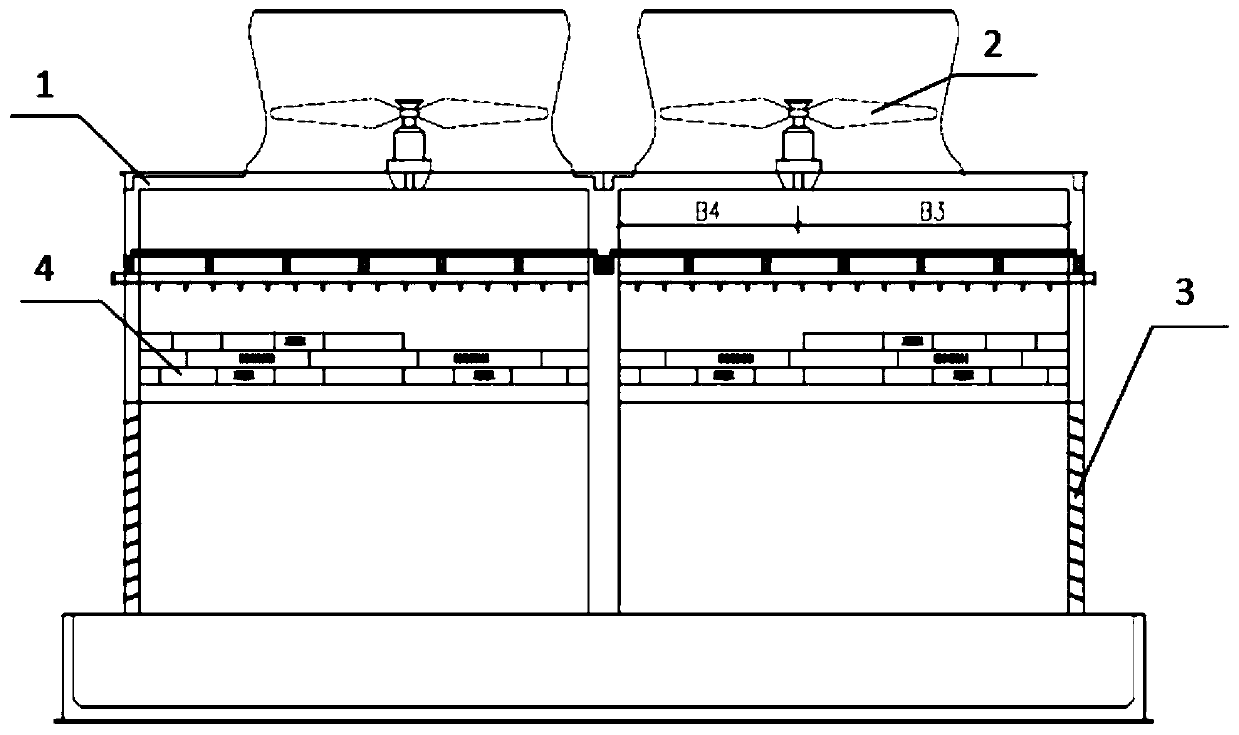

Optimized single-side air inlet induced draft tower

The invention discloses an optimized single-side air inlet induced draft tower. The induced draft tower comprises a tower body, fans and padding. An air inlet is formed in the tower body. The paddingis divided into a windward side padding body and a leeward side padding body. The distance between the center lines of the fans and the windward side inner wall surface of the tower body is B3, and the distance between the center lines of the fans and the leeward side inner wall surface of the tower body is B4 (please see the ratio of B3 to B4 in the specification). By optimizing the parameters such as the fan arrangement position, the height of the air inlet, the height and width of the padding and the water spraying density, the inlet air dead zone is reduced, and the inlet air in the toweris optimized; and the cooling effect of a rain area and the padding in the tower is fully utilized, so that the cooling performance of the entire induced draft tower is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

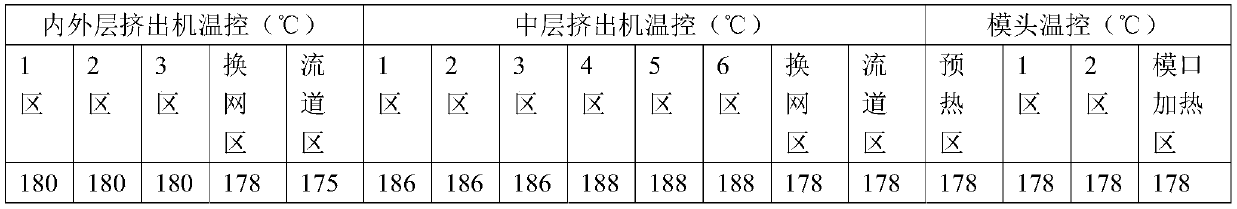

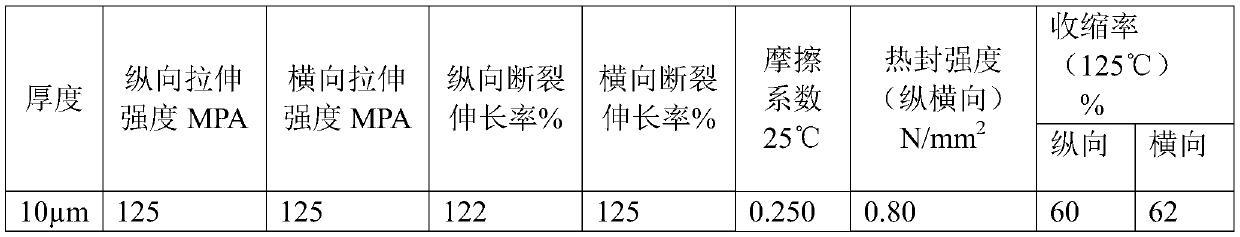

Thin polyolefin shrink film and production process thereof

ActiveCN110303748AHigh strengthGood heat sealingSynthetic resin layered productsFlat articlesLinear low-density polyethylenePolymer science

The invention discloses a thin polyolefin shrink film and a production process thereof. According to the invention, raw materials of inner and outer surface layers and raw materials of an intermediatelayer are prepared by a twice blow-up process, wherein the raw materials of the inner and outer surface layers comprise a ternary random polypropylene copolymer, an anti-sticking agent and a slippingagent; and the raw materials of the intermediate layer comprise octacarbon linear low-density polyethylene, metallocene LLDPE and a slipping agent. According to the invention, through adjustment of aformula and a process, the thickness of a film is reduced, so second bubbles are easier to be formed, and physical and mechanical properties of the film is not lower than the physical and mechanicalproperties of a POF film with a thickness of 10 [mu]m or above; meanwhile, the problems like lower hot-sealing performance with lower thinness of the film and easy pleating and difficult slitting in the process of slitting are overcome.

Owner:山东联众包装科技有限公司

Dual-fuel low-speed machine cooling system on LNG power ship

InactiveCN110878725AReduce the temperatureFulfil requirementsLiquid coolingInternal combustion piston enginesWater flowProcess engineering

The invention discloses a dual-fuel low-speed machine cooling system on an LNG power ship. The system comprises: an LNG gasification module, wherein the LNG gasification module comprises two sides capable of conducting heat exchange, one side of the LNG gasification module is connected into natural gas flow paths in series, and the other side of the LNG gasification module is connected into ethylene glycol flow paths in series; a cooling system heat exchanger, wherein the cooling system heat exchanger comprises two sides capable of exchanging heat, one side of the cooling system heat exchangeris connected into the ethylene glycol flow paths in series, and the other side of the cooling system heat exchanger is connected into fresh water flow pathes in series; and a dual-fuel low-speed machine. Cold energy generated by LNG fuel on the LNG power ship is recycled, the cold energy is transmitted to the dual-fuel low-speed machine cooling water system, and the purposes of reducing the dual-fuel low-speed machine cooling water temperature, optimizing and propelling the energy consumption index of the dual-fuel low-speed machine and improving the environmental friendliness are achieved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Furnace cap water-cooling device for converter

InactiveCN101812565APromote circulationLower the cooling water temperatureManufacturing convertersProcess efficiency improvementSlagCooling effect

The invention relates to a furnace cap water-cooling device for a converter and belongs to the technical field of auxiliary devices of a converter. The furnace cap water-cooling device for the converter comprises a steel tube arranged on the outer surface of the furnace cap; the steel tube is divided into at least three sections along the circumference of the furnace cap; the sections of the steel tube are arranged in a snake shape at intervals along the outer surface of the furnace cap and are provided with a gap for accommodating a slag-blocking skirt support plate respectively; and head and tail ends of each section of the steel tube are connected with a water inlet pipe and a water outlet pipe respectively. The cooling water in each section of the steel tube of the furnace cap water-cooling device for the converter only densely flows through a smaller region of the outer surface of the furnace cap, so that the circulation of the cooling water is accelerated, the area covering the outer surface of the furnace cap is increased, and the water temperature is reduced. Therefore, the cooling effect of the furnace cap is greatly improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

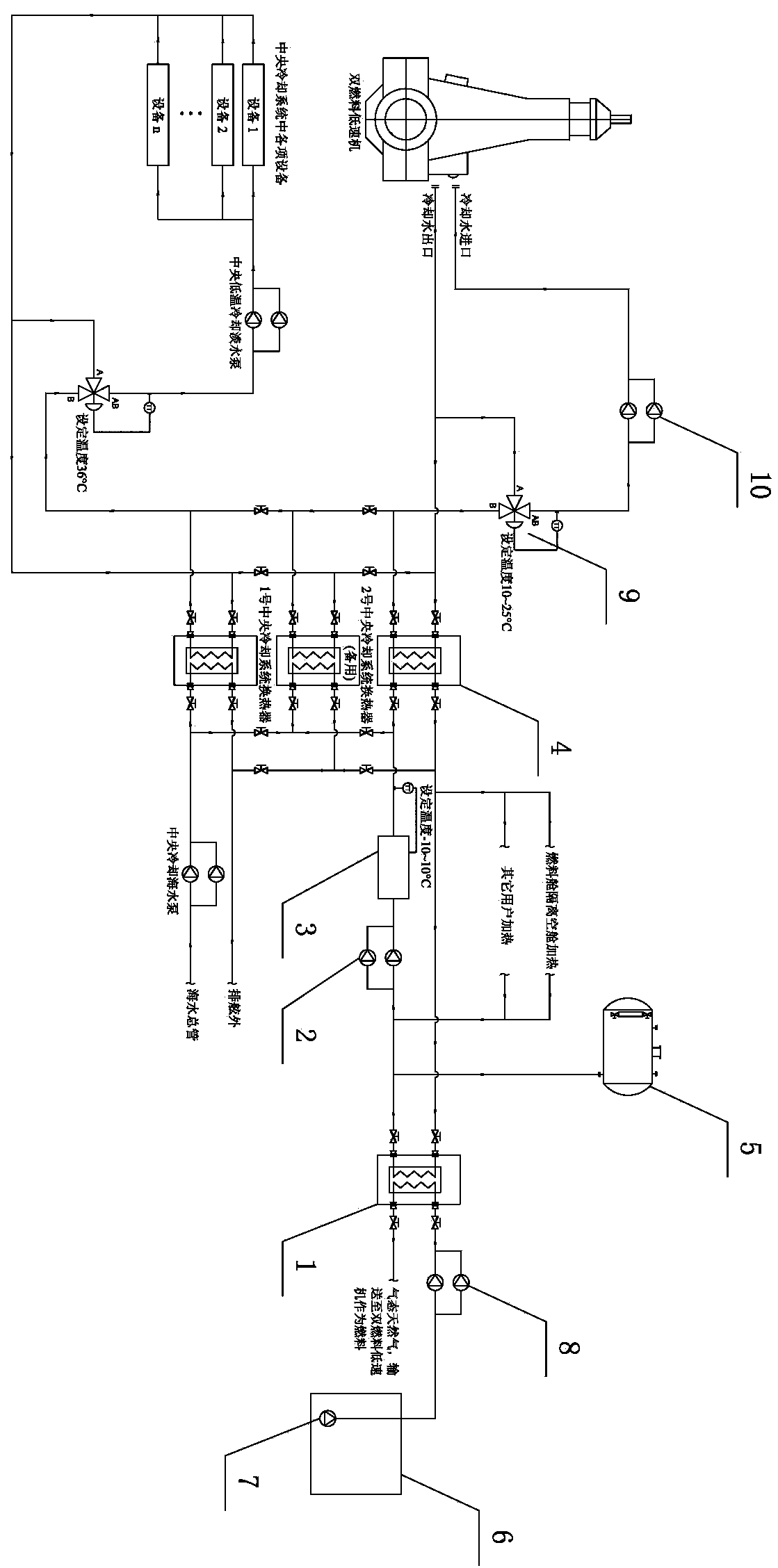

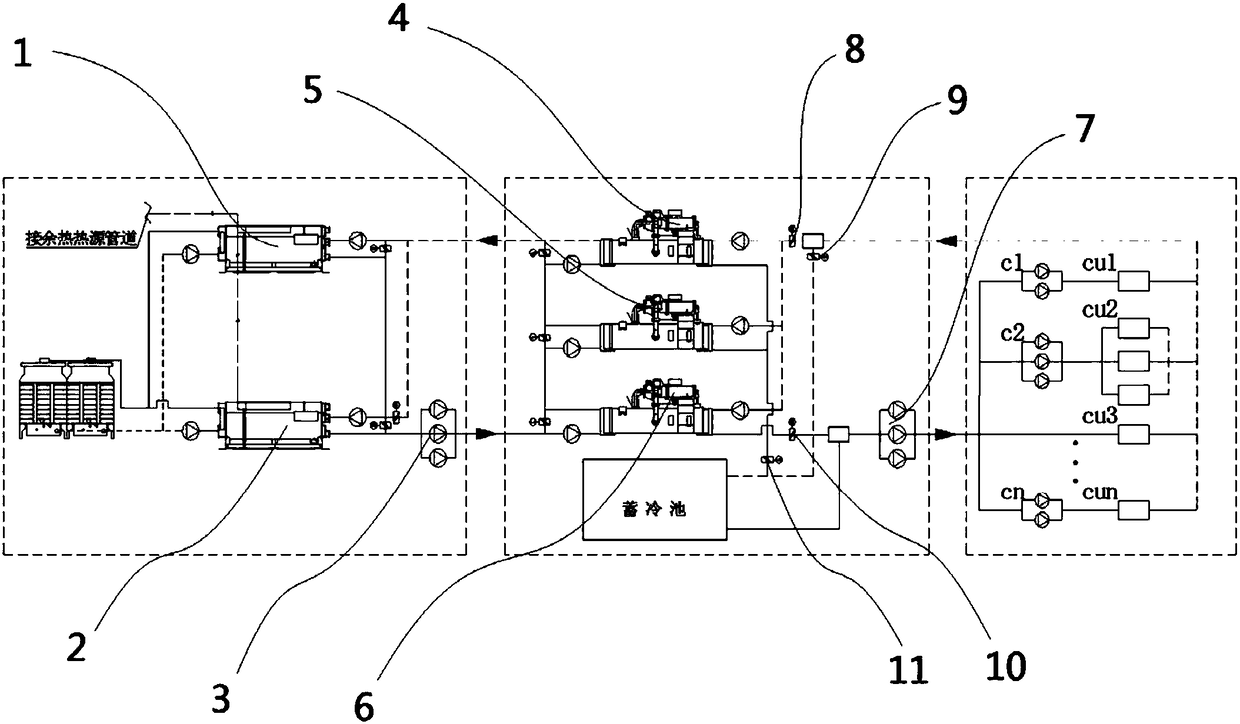

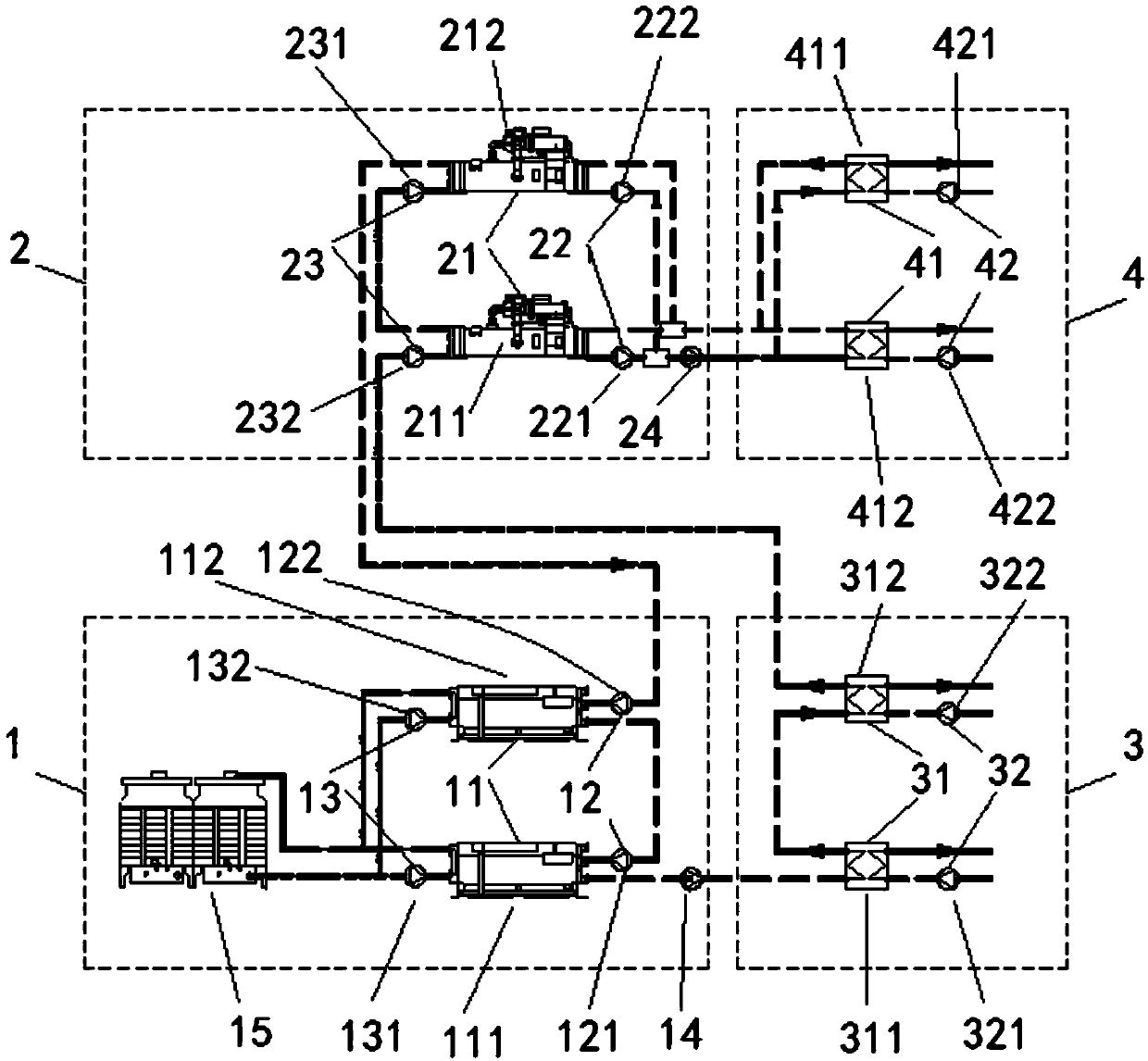

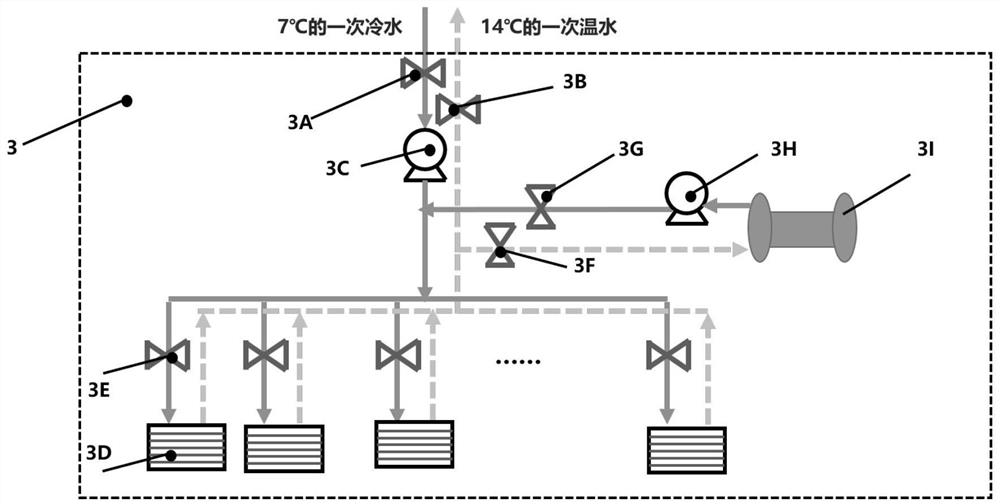

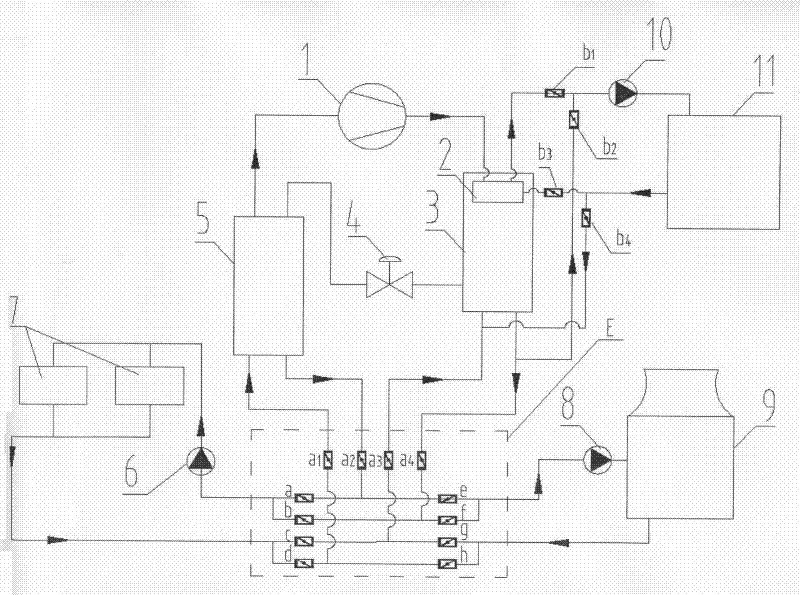

Modular area cooling system

ActiveCN108180674ARelease cooling capacityImprove operational efficiencyHeat pumpsEfficient regulation technologiesElectricityModularity

The invention discloses a modular area cooling system. The cooling system comprises a cooling system, a refrigerating and cold storage system and a variable frequency distribution pump system, whereinthe cooling system comprises a waste heat source pipeline, a waste heat absorption type water chilling unit a1, a cooling system waste heat absorption type water chilling unit a2 and a cooling waterconveying water pump BQ; the refrigerating and cold storage system comprises a water-cooled electric cooling water chilling unit b1, a water-cooled electric cooling water chilling unit b2, a water-cooled electric cooling water chilling unit b3, an electric butterfly valve v1, an electric butterfly valve v2, an electric butterfly valve v3, an electric butterfly valve v4, a cold storage tank, a water distributor and a chilled water secondary pump BL; the cooling water conveying water pump BQ is used for conveying cooling water to a cold supply station, and the water-cooled electric cooling waterchilling units b1, the water-cooled electric cooling water chilling unit b2 and the water-cooled electric cooling water chilling unit b3 are used for extracting cooling water according to requirements by utilizing split cooling water pumps and utilizing the cooling water step by step; and the water-cooled electric cooling water chilling unit b1, the water-cooled electric cooling water chilling unit b2 and the water-cooled electric cooling water chilling unit b3 are connected with the cold accumulation pool in series and in parallel in a switched operation working condition through the electric butterfly valve v1, the electric butterfly valve v2, the electric butterfly valve v3 and the electric butterfly valve v4. According to the system, the installed capacity and the running efficiency of the cold supply station can be improved, and the advantages of intensive cooling, intensive energy utilization and efficient utilization of energy can be brought into full play.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTH CHINA UNIV OF TECH

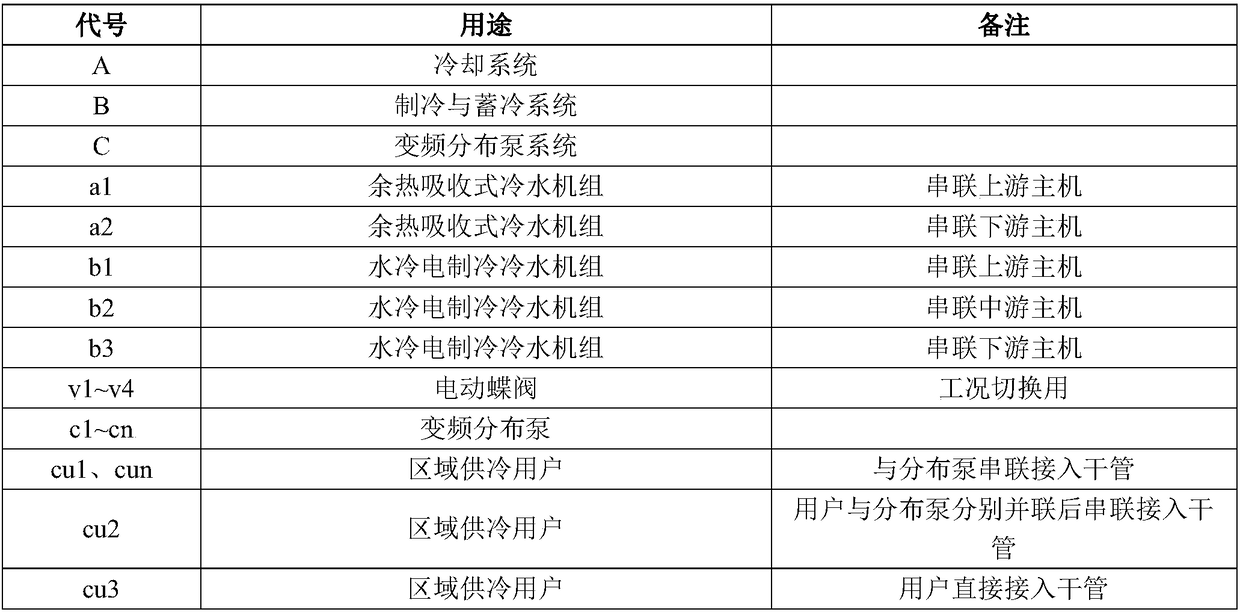

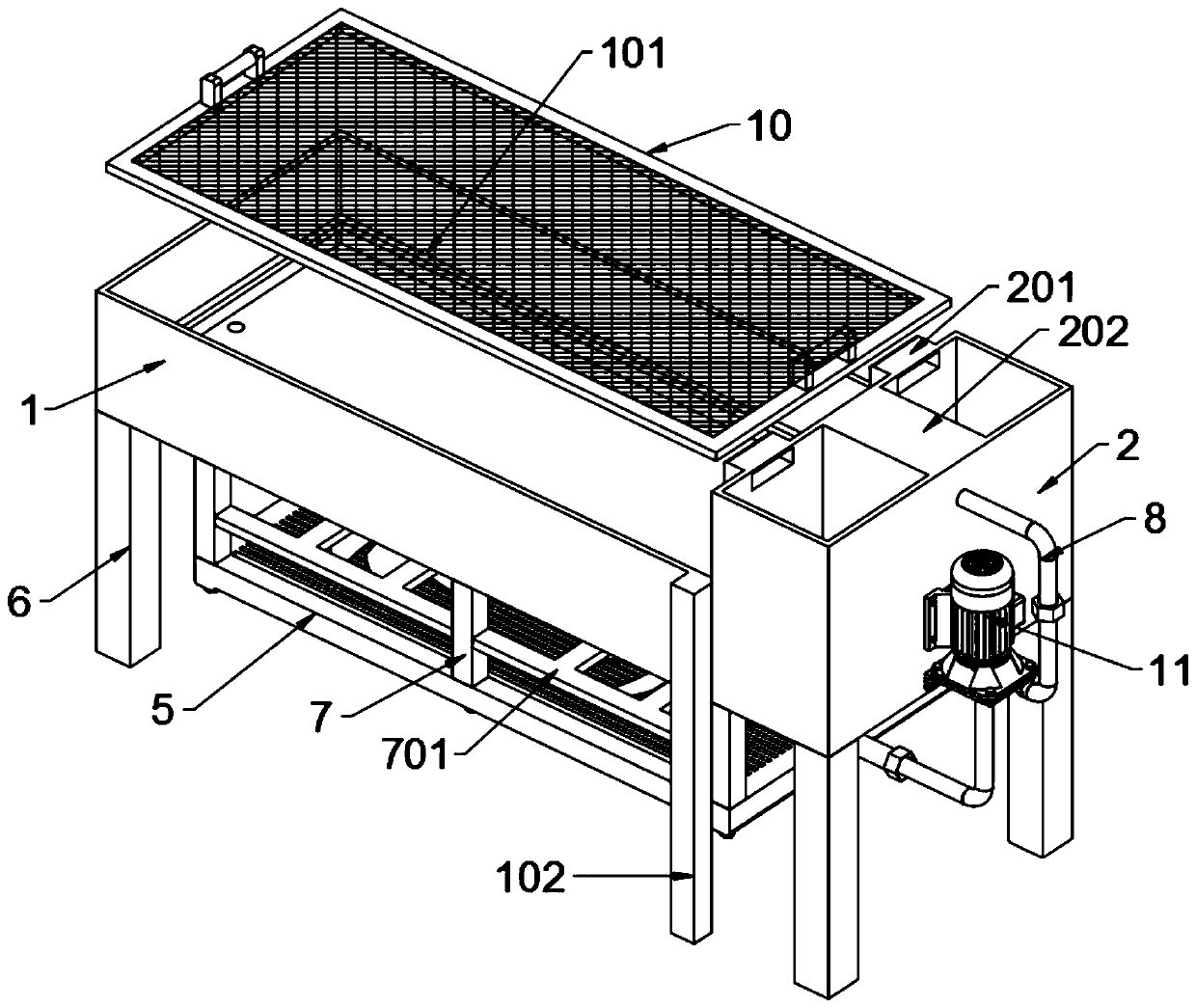

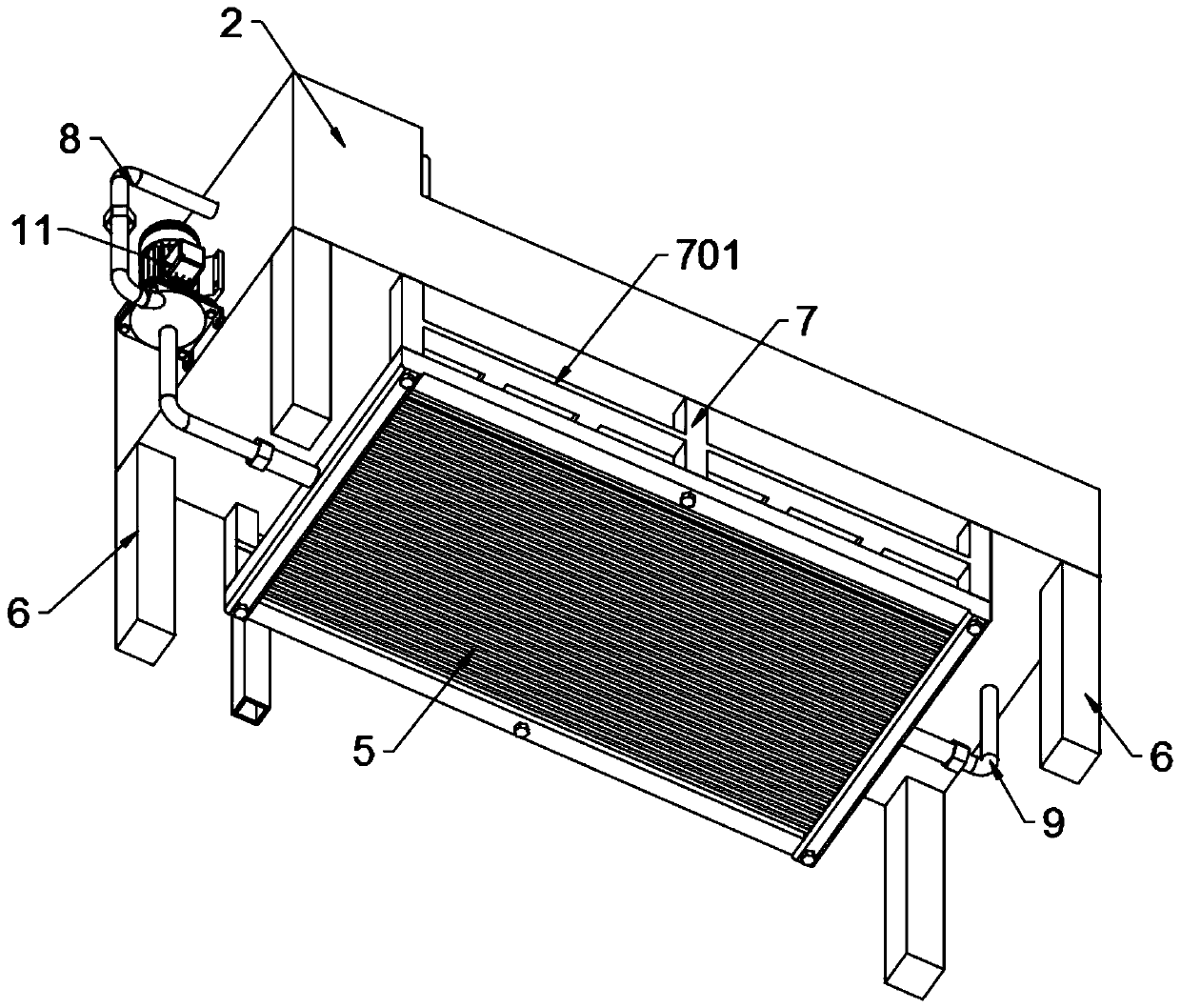

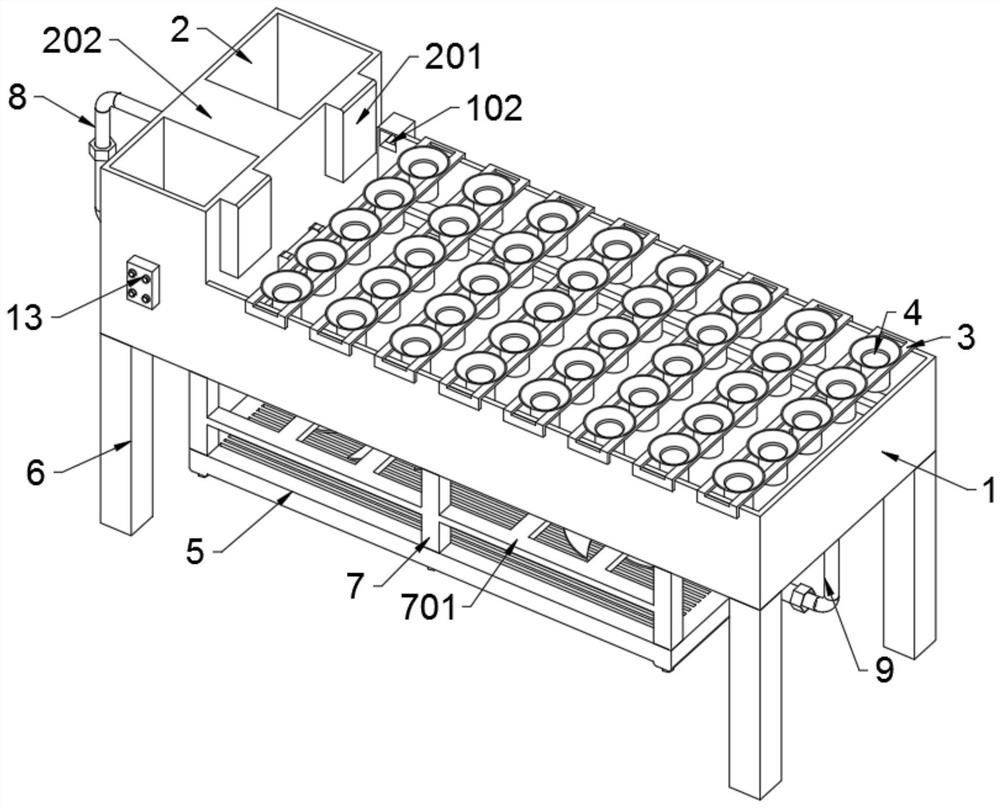

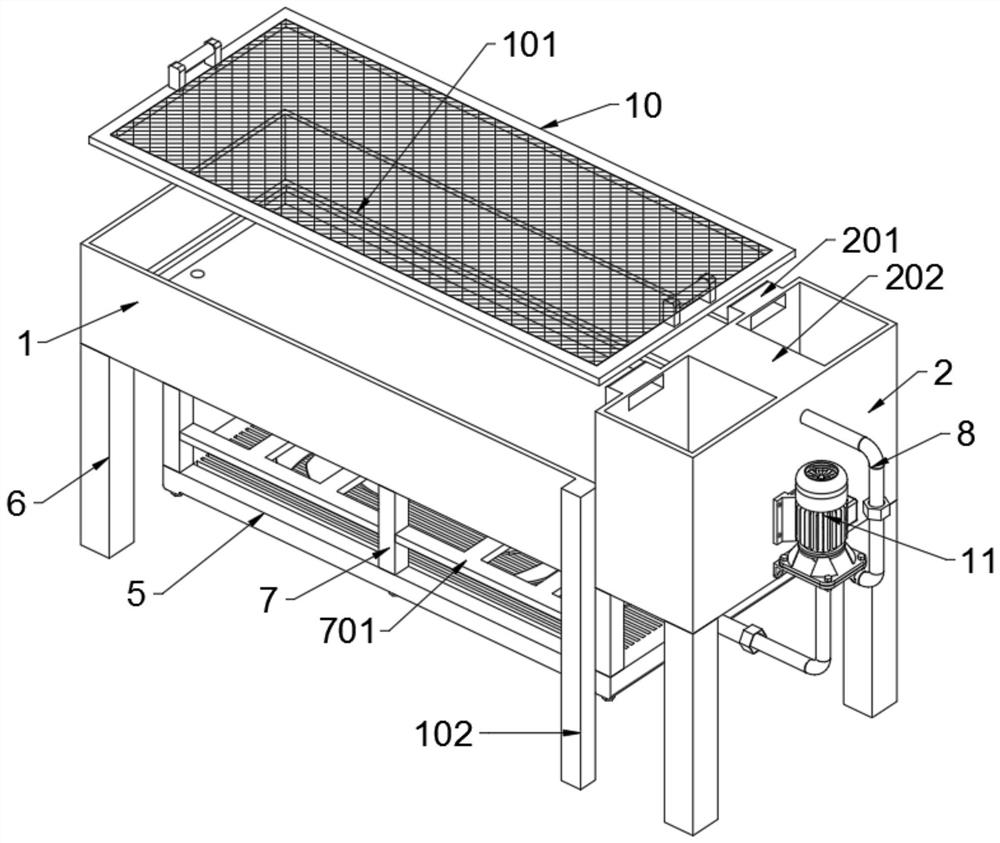

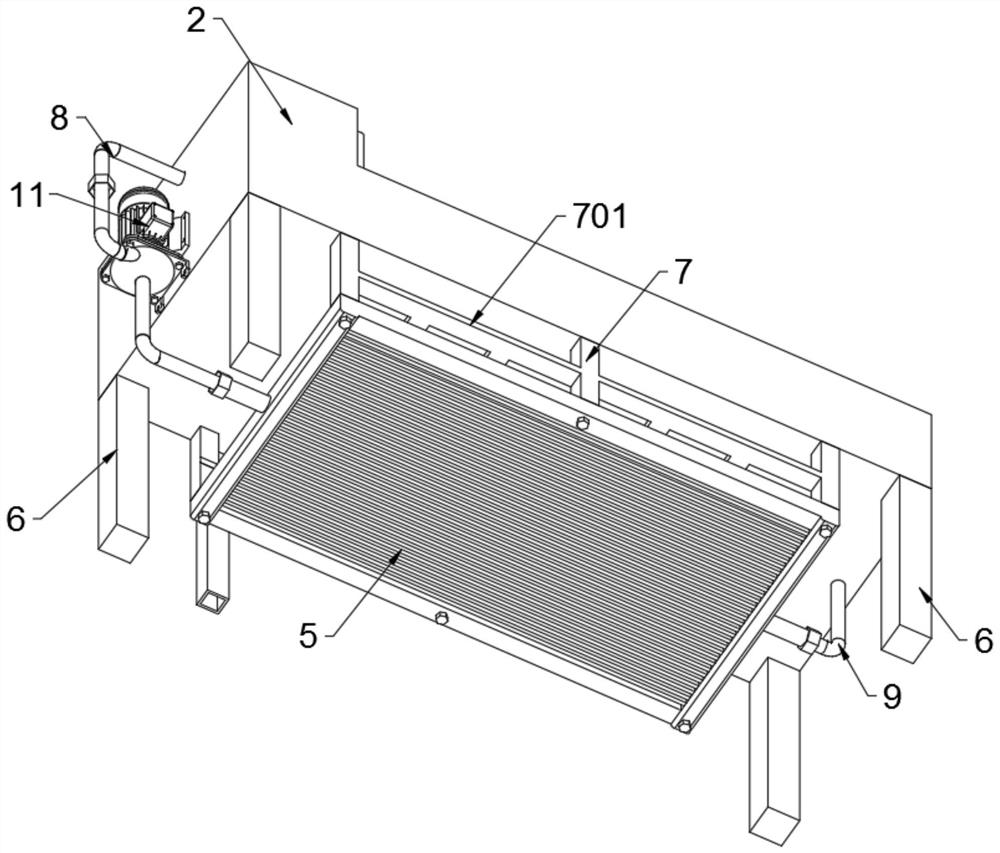

Wax mold manufacturing cold water device

ActiveCN110976759AGood cooling effectPrevent splashing aroundDomestic cooling apparatusLighting and heating apparatusThermodynamicsEngineering

The invention provides a wax mold manufacturing cold water device. The wax mold manufacturing cold water device comprises an overflow pipe, an ice block box, a spill pipe, a water inlet groove, a fanand a control panel box; a cold water tank main body is totally rectangular, and the left end is welded with the ice block box; four support legs are symmetrically supported at the left and right endsof the bottom of the cold water tank main body; the tail section of a water absorbing pipe is bent to the left side, and is lifted in the right side position of a base plate of the cold water tank main body in a through welding mode; two leakage plates are provided with multiple leakage grooves at equal intervals in a penetrating mode; a water pump is locked and fixed in the middle position of the outer wall of the left side of the ice block box through screws; and a mold frame is provided as a carrier of a wax mold cylinder, and can support the wax mold cylinder to dip in cooling water in the cold water tank man body for cooling wax liquid in the wax mold cylinder.

Owner:宁海凯汇日用品有限公司

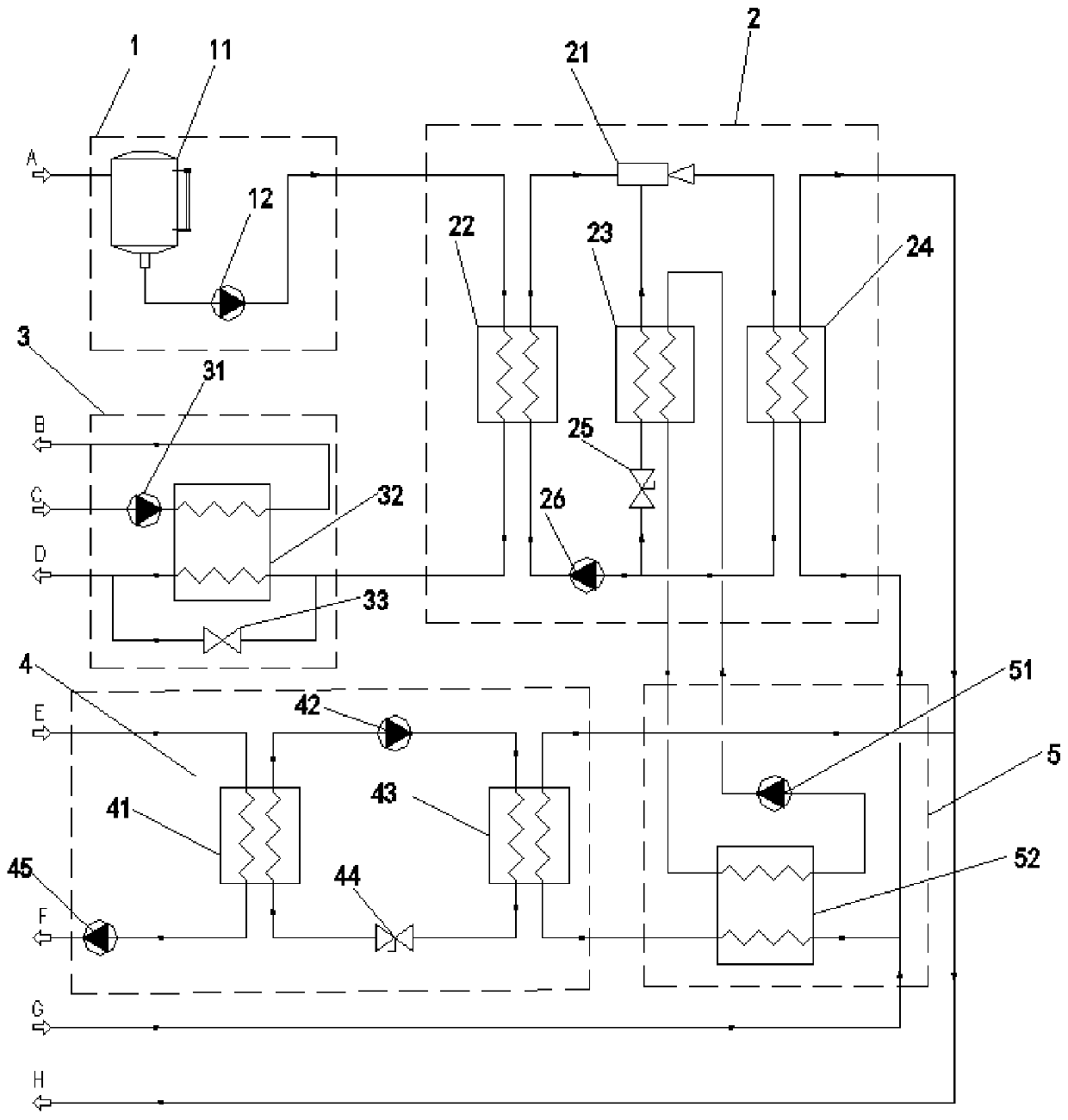

Large-temperature-difference cold water composite gradient utilization system based on waste heat utilization

PendingCN107764122AImprove primary energy utilizationIncrease return water temperatureRecuperative heat exchangersWater circulationWater pipe

The invention discloses a large-temperature-difference cold water composite gradient utilization system based on waste heat utilization. The large-temperature-difference cold water composite gradientutilization system comprises a waste heat absorption type large-temperature-difference gradient refrigeration system, a chilled water gradient utilization system, a cooling water gradient utilizationsystem and a district cooling user system. The waste heat absorption type large-temperature-difference gradient refrigeration system supplies cold water to the chilled water gradient utilization system through a pipeline. The chilled water gradient utilization system supplies cold water to the cooling water gradient utilization system through a pipeline. The cooling water gradient utilization system supplies cold water to the district cooling user system. Hot water of the cooling water gradient utilization system flows back to the waste heat absorption type large-temperature-difference gradient refrigeration system to be cooled. According to the large-temperature-difference cold water composite gradient utilization system, waste heat of a thermal power plant is utilized for carrying out absorption type refrigeration; waste heat and exhaust heat gradient utilization is achieved; the primary energy utilization ratio is increased; the water return temperature is improved; the water supplyand return temperature difference of the district cooling system is increased; the cold water use temperature difference is enlarged; the circulating water amount of cold water is greatly reduced; pipe network conveying energy consumption and cold losses are reduced; and cold water pipe network conveying energy consumption is reduced.

Owner:济南热力集团有限公司 +2

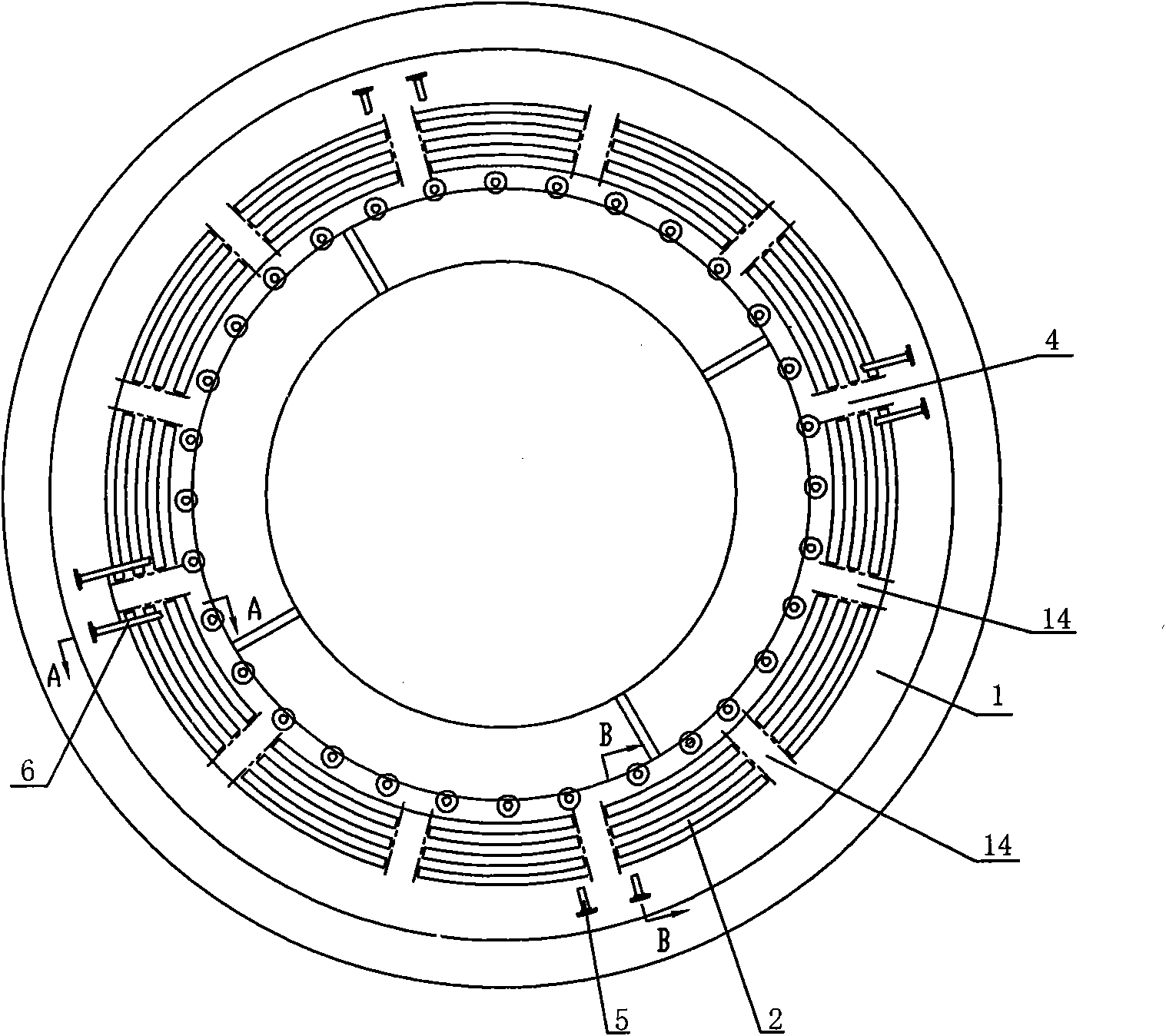

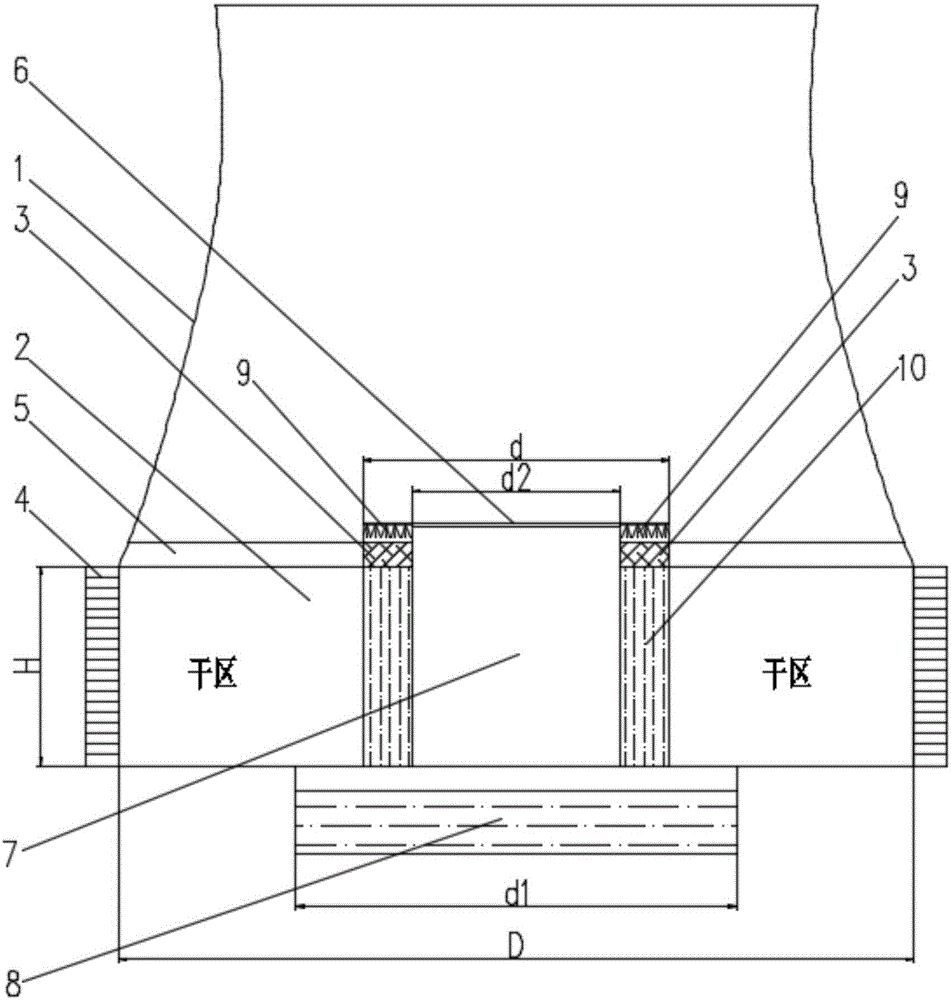

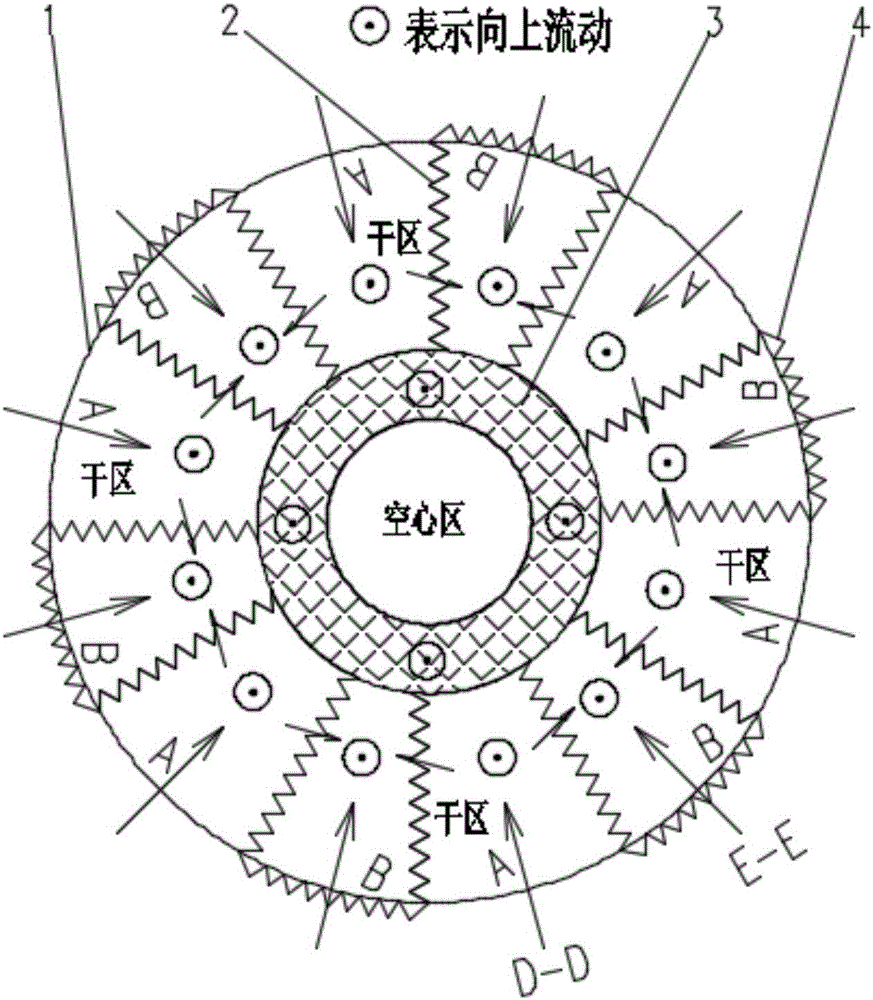

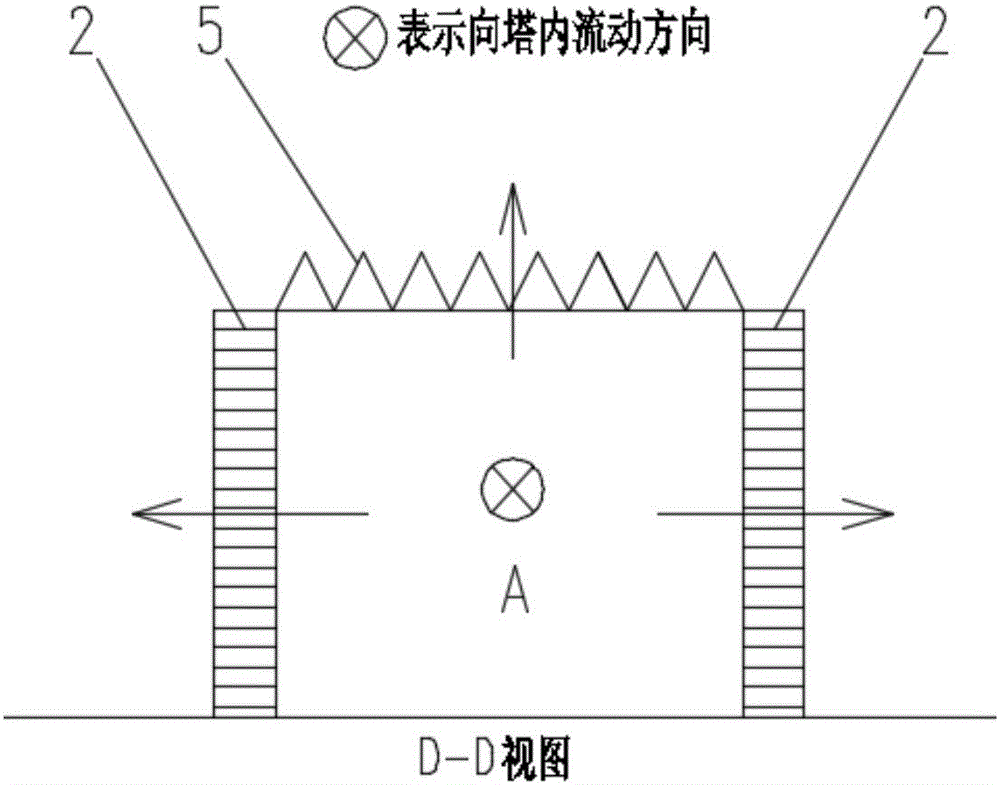

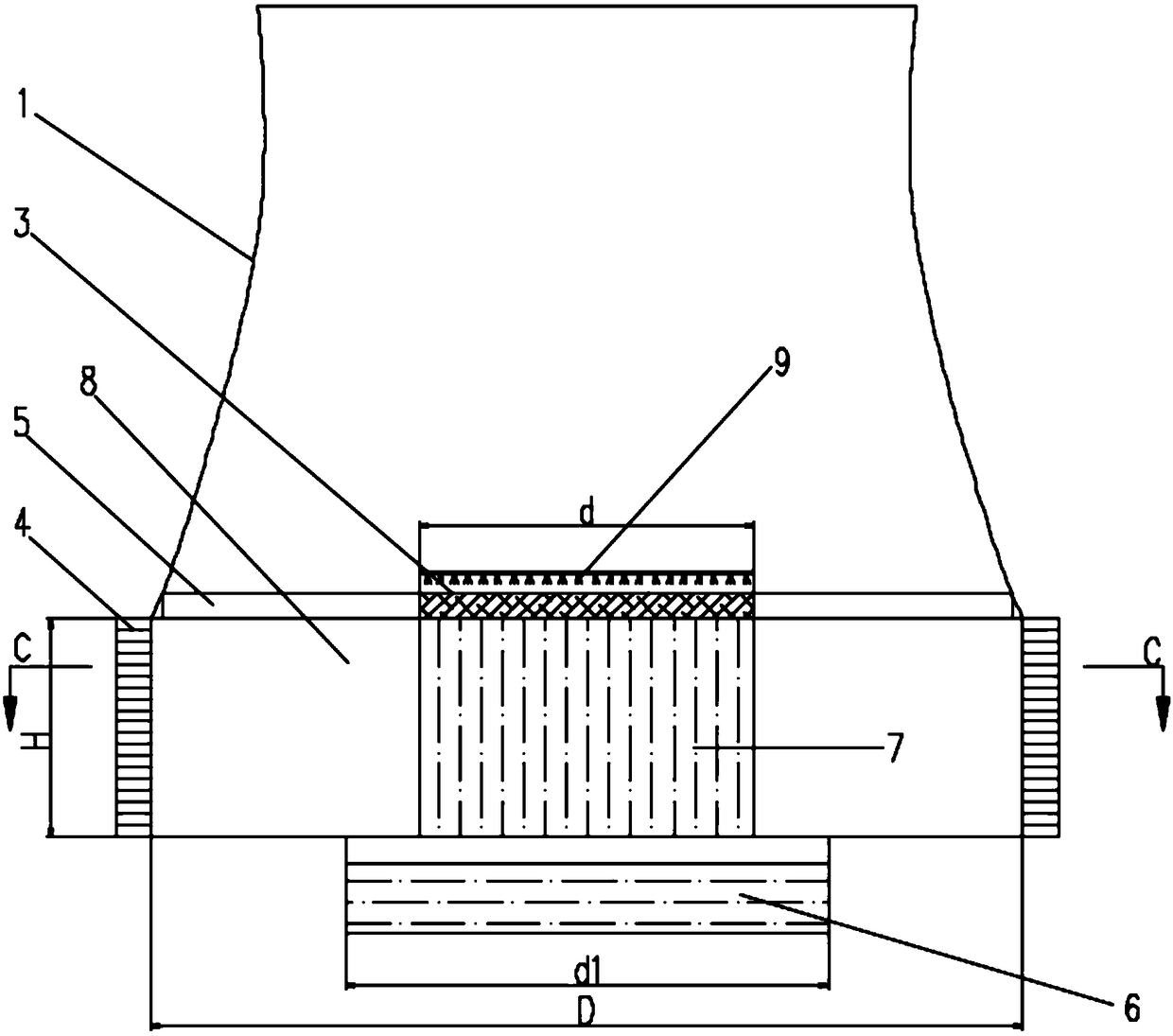

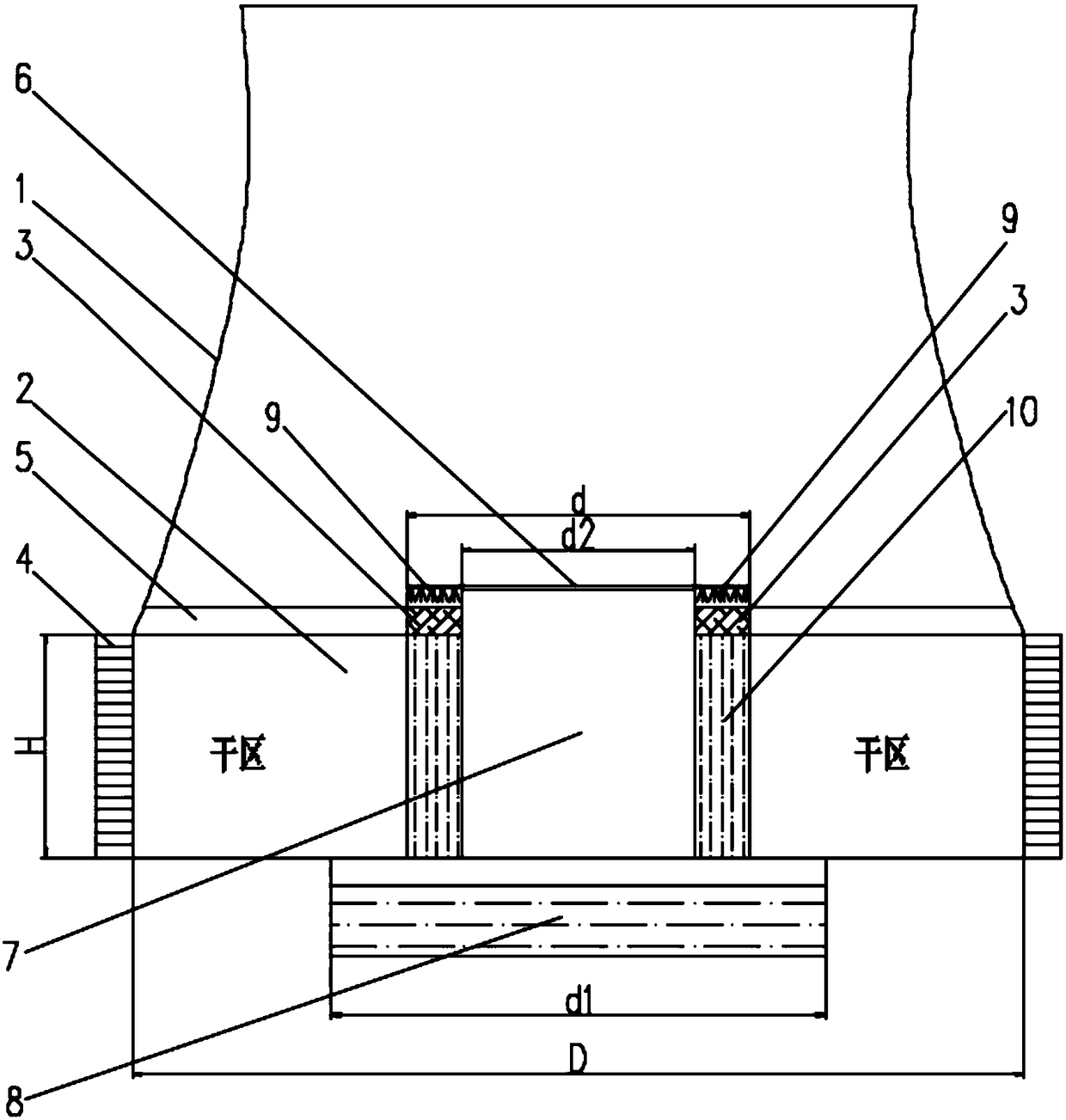

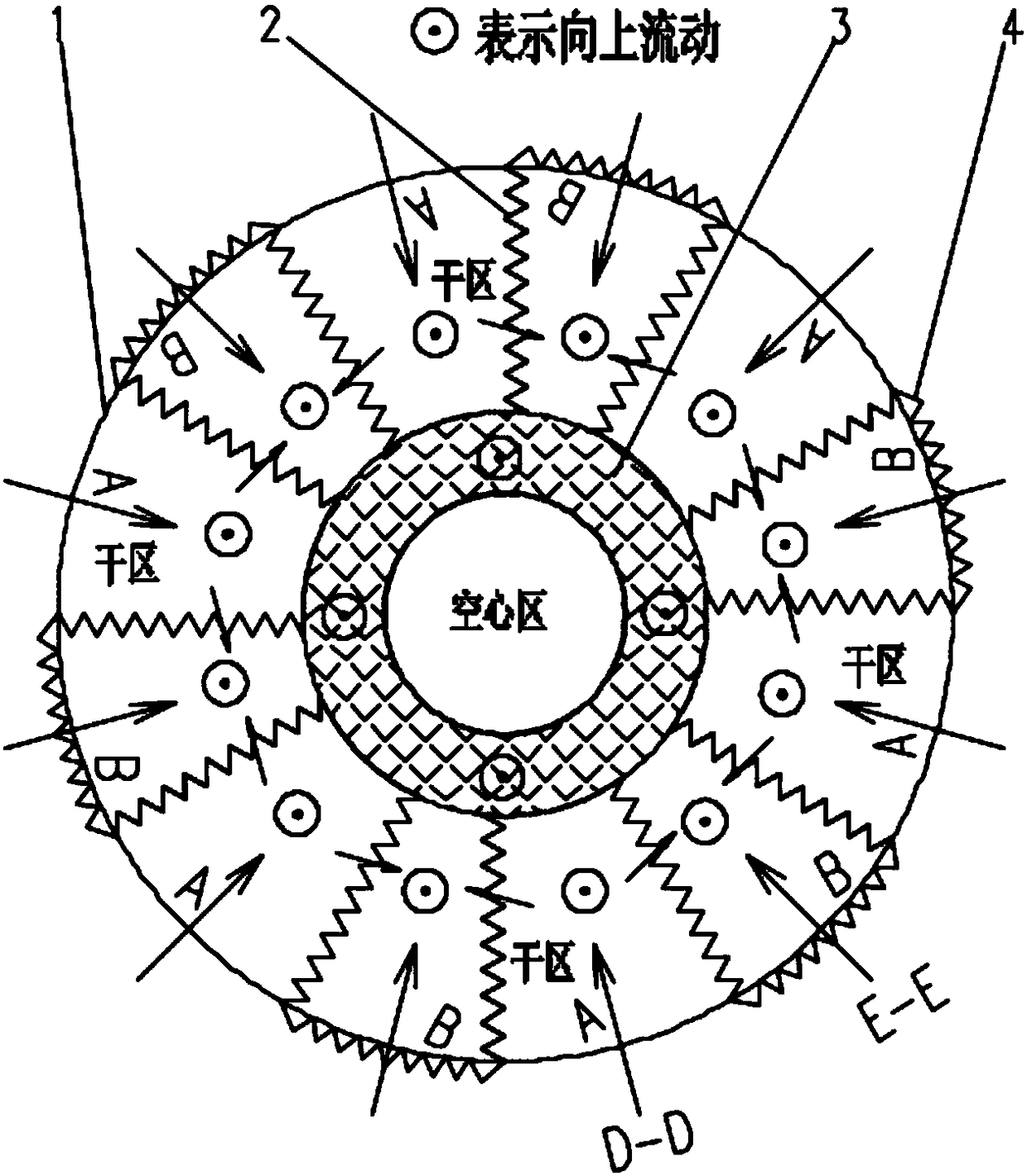

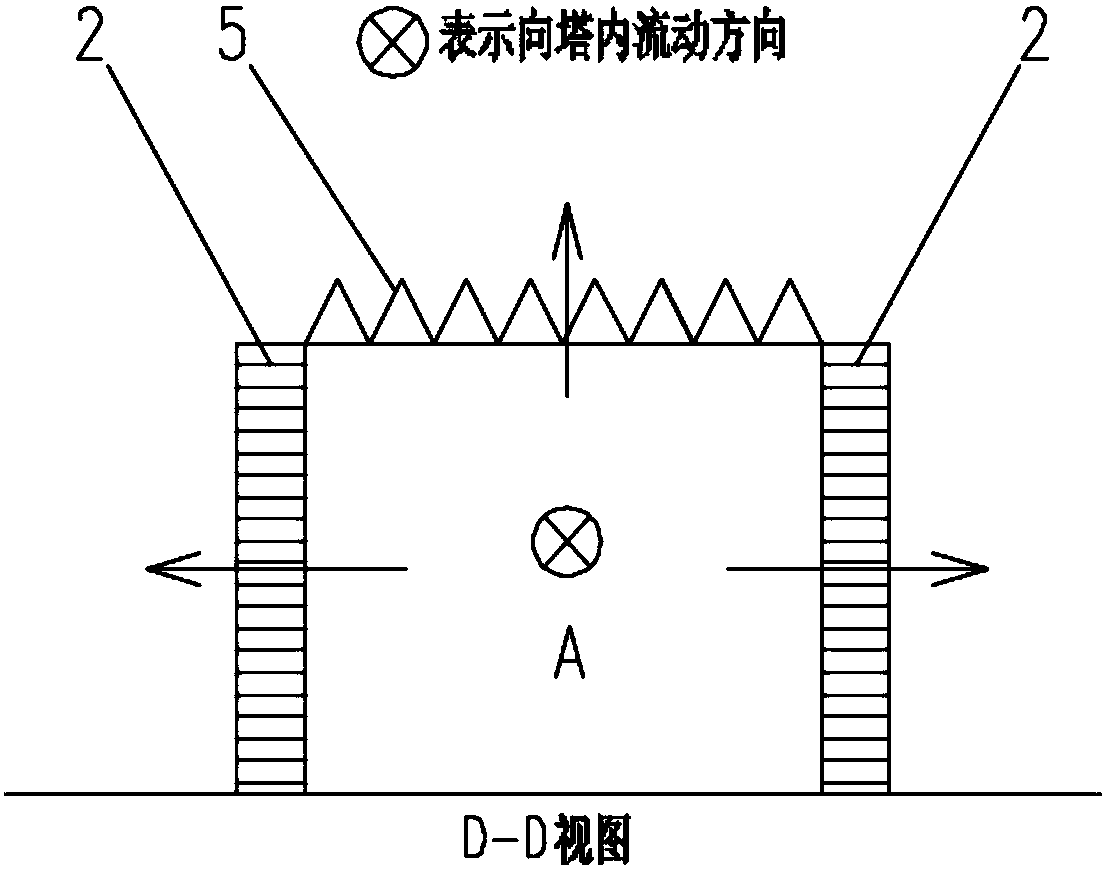

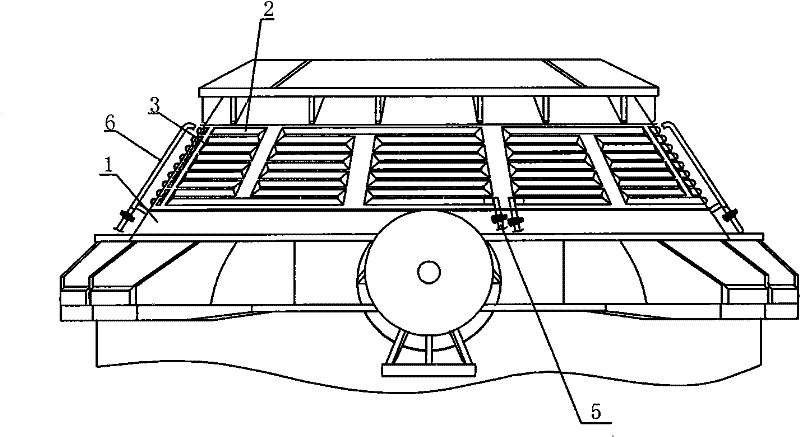

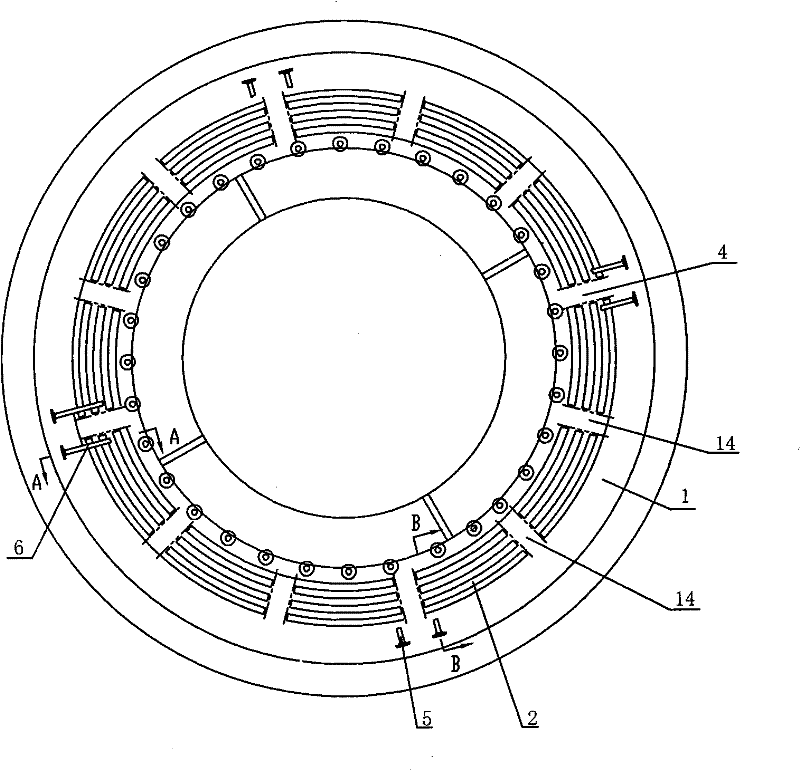

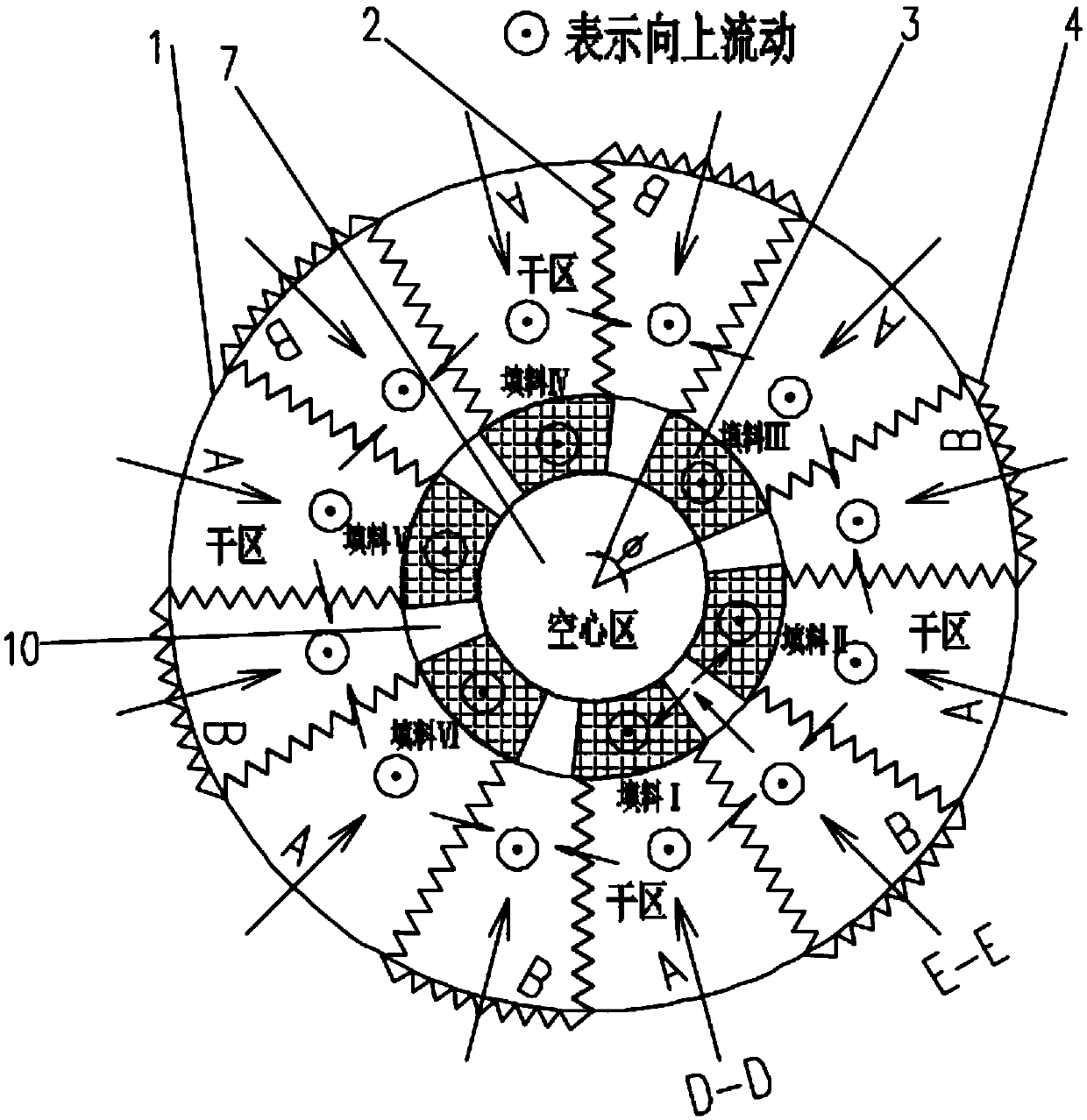

Dry and wet blended large-scale cooling tower with filler being annularly arranged and cooling system of thermal power plant

ActiveCN106643205ALow ventilation resistanceLess investmentTrickle coolersCooling towerCooling effect

The invention relates to a dry and wet blended large-scale cooling tower with filler being annularly arranged and a cooling system of a thermal power plant and belongs to the field of energy and power engineering. The cooling tower comprises a cooling tower drum. The lower side of the cooling tower drum is sequentially provided with dry area air inlet cooling units, a dry area in-tower perpendicular cooling unit, a wet area filler area and a wet area hollow area from outside to inside. A dry area in-tower horizontal cooling unit is arranged on the upper portion of the dry area in-tower perpendicular cooling unit. The top of the wet area hollow area is provided with a cover plate. The bottom of the wet area hollow area is a wet type water collecting pool. A water distributing area and the filler area of the wet area are both annular. By the adoption of the dry and wet blended large-scale cooling tower with the filler being annularly arranged, because the brand new structure is designed, through the cooling units of different structures in the dry area, the annular-structure filler area and the annular-structure water distributing area, the wind resistance is greatly lowered, the ventilation cooling effect is guaranteed, and the heat exchange performance of the wet area is improved.

Owner:SHANDONG UNIV

Nanodiamond Self-Repair Fluid for Piston Engines

The invention discloses a nano-diamond automatic repair liquid for a reciprocating piston engine. The liquid is characterized by being prepared by the following steps: (1) adding a nano-diamond into a dispersant OP-10, stirring for over 20 minutes, then standing, and after bubbles fully disappear and black precipitates appear at the bottom, pouring out a supernate, wherein the nano-diamond is a spherical particle, the grain size of which is 2-4n, and the addition proportion of OP-10 and the nano-diamond is 0.8-1.2mg of nano-diamond per L of OP-10; and (2) adding the supernate into lubricating oil, and stirring and mixing to obtain the automatic repair liquid, wherein the weight ratio of the supernate and the lubricating oil in percentage by weight is (10-30%):(90-70%). The nano-diamond in the automatic repair liquid is good in dispersing effect and stable and can be placed for a long time. The repair liquid is simple in formula, low in cost and simple in preparation method.

Owner:CHONGQING HAILIYUN TECH

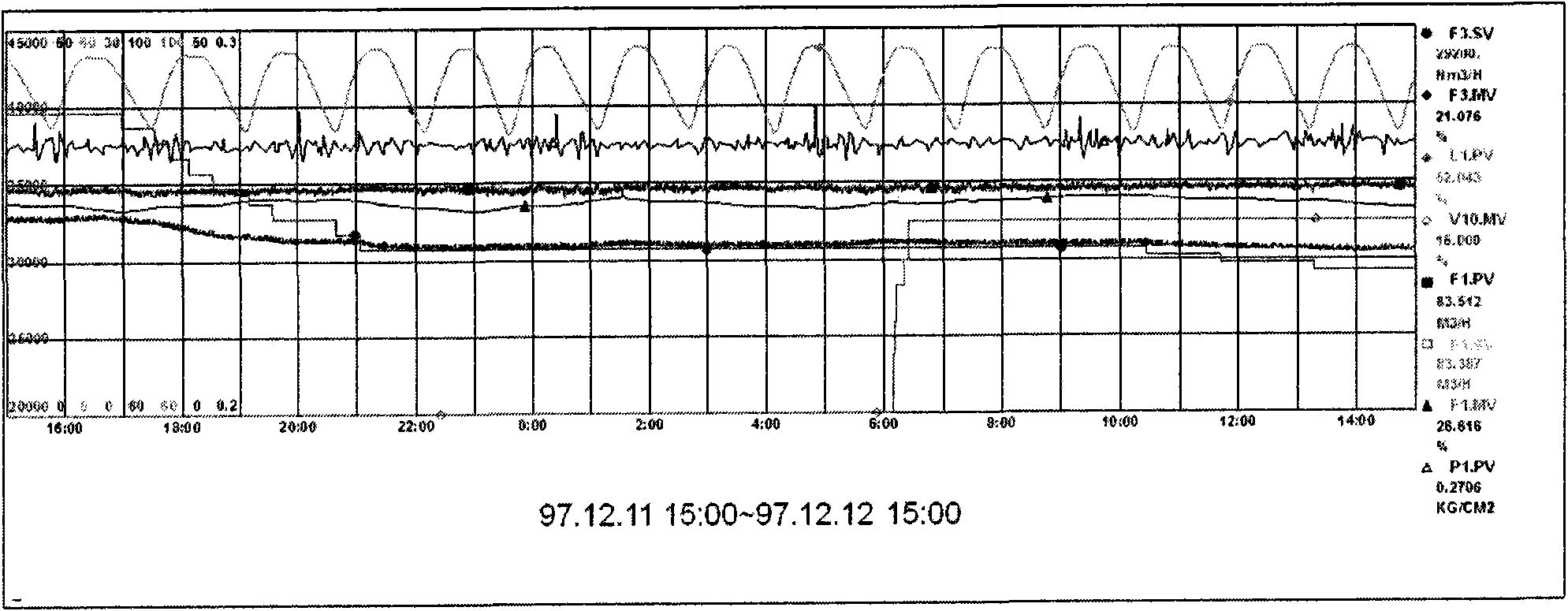

Nitrogen yield increasing method for use in air separation unit

InactiveCN102466390AIncrease productionImprove freezing effectSolidificationLiquefactionCooling towerCooling effect

The invention relates to a nitrogen yield increasing method and device for use in an air separation plant, particularly to the improvement of a nitrogen water precooling system for use in the air separation plant. The nitrogen flow of the nitrogen water precooling system is reduced and the nitrogen is guided into a nitrogen compressor for future use. In order to enable gas entering into a molecular sieve absorption system to be without higher saturated water vapor, the absorption effect is reduced. The nitrogen yield increasing method improves the refrigerating capacity of a refrigerator and can reduce the temperature of the cooling water entering in an air cooling tower and the temperature of the air exiting from the air cooling tower, enhance the cooling effect of the air cooling tower and therefore increase the yield of nitrogen products. According to the nitrogen yield increasing method provided by the invention, the usage amount of air separation units can be reduced, and with respect to the increment of the usage amount or capacity of refrigerators although, more energy consumptions can be saved.

Owner:CHINA STEEL

Bent pipe medium-frequency heating device with heating and cooling functions

PendingCN113699334AFast heatingHeating evenlyShaping toolsIncreasing energy efficiencyTemperature controlEngineering

The invention discloses a bent pipe medium-frequency heating device with heating and cooling functions, and relates to the technical field of bent pipe manufacturing equipment. The bent pipe medium-frequency heating device with the heating and cooling functions comprises an induction coil, alternating positive and negative electrodes are arranged at the top of the induction coil, high-frequency insulating ceramics with spraying holes are arranged on the induction coil at intervals, a water inlet pipe is connected between every two adjacent high-frequency insulating ceramics, and each water inlet pipe communicates with the corresponding high-frequency insulating ceramics. The water inlet pipes are connected with a spraying system for supplying water. The induction coil is used for non-contact heating, the temperature rising speed is high, heating is uniform, and the temperature control precision is further improved; local heating can be achieved, control is easy, labor is saved, workpieces in complex shapes can be heated, and the application range is wide; a plurality of spraying water holes are formed in the high-frequency insulating ceramic in each area according to actual requirements, so that the problem that the temperature of the circumferential section of the steel pipe is not uniform is solved.

Owner:NANJING IRON & STEEL CO LTD +2

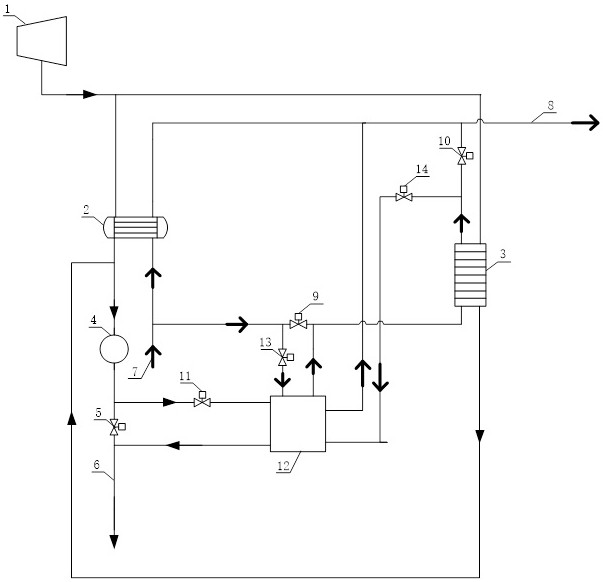

An improved primary heating station system and its working method

ActiveCN111765507BLower the cooling water temperatureHigh outputLighting and heating apparatusSpace heating and ventilation detailsHigh energyEngineering

The invention discloses an improved heating first station system and its working method. At present, there is no improved heating first station with a reasonable structural design, which can effectively increase the output of small steam turbines, reduce the drain temperature of the heating network and increase the water supply temperature. system. The system of the present invention includes a steam turbine, a heat network heater, a small steam turbine condenser, a heat network drain pump, a heat network drain main pipe, a heat network return water main pipe, and a heat network water supply main pipe; The steam inlet of the network heater is connected with the steam inlet of the condenser of the small steam turbine, the drain outlet of the heat network heater is connected with the inlet of the heat network drain pump, the outlet of the heat network drain pump is connected with the inlet of the heat network drain main pipe valve, The outlet of the main drain pipe valve of the heat network is connected to the main drain pipe of the heat network, and the drain outlet of the condenser of the small steam turbine is connected near the inlet of the drain pump of the heat network. The invention has high energy utilization efficiency and good economic benefits, and can be well applied to the reconstruction and expansion of the first heat supply station using small steam turbines.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

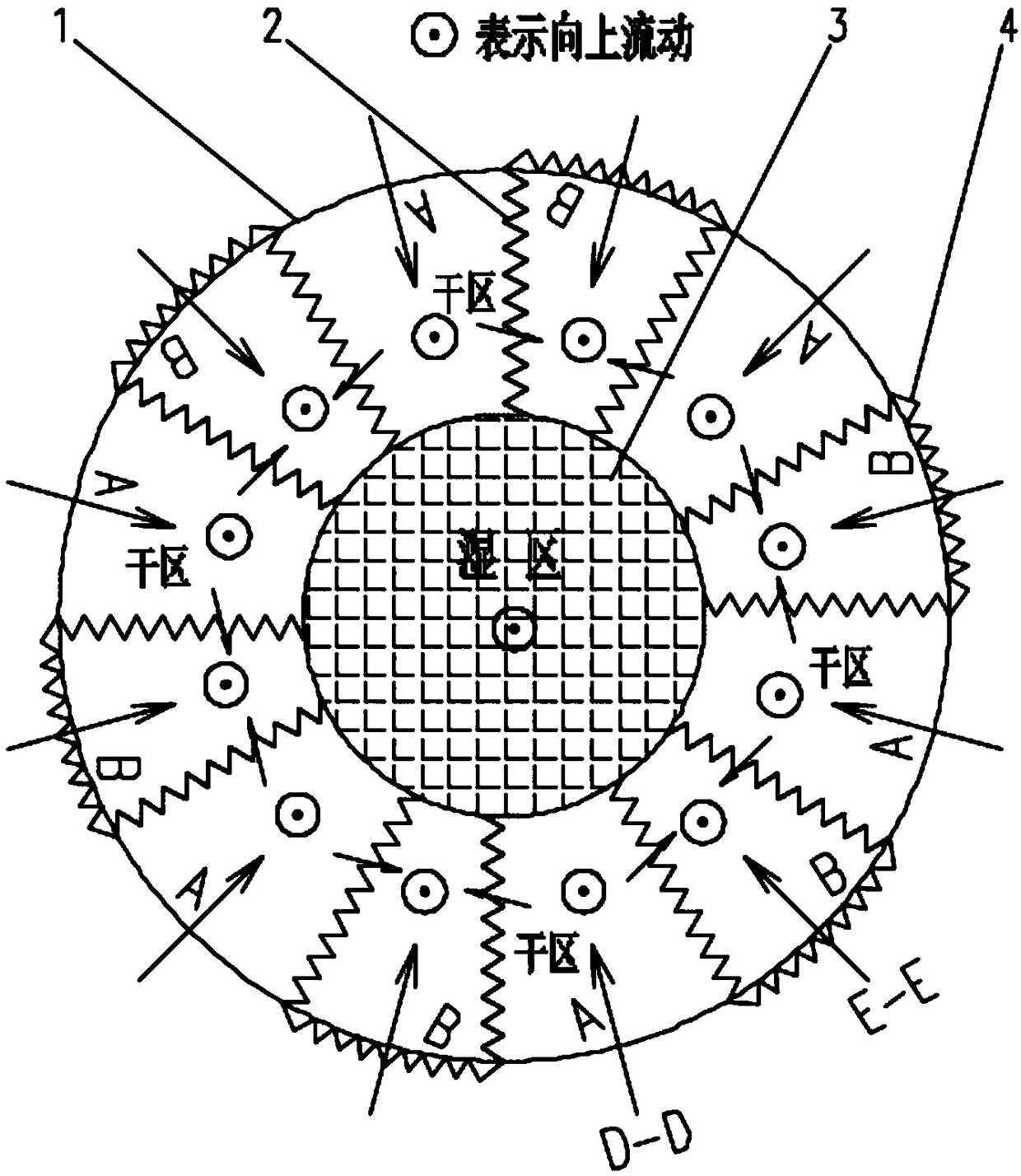

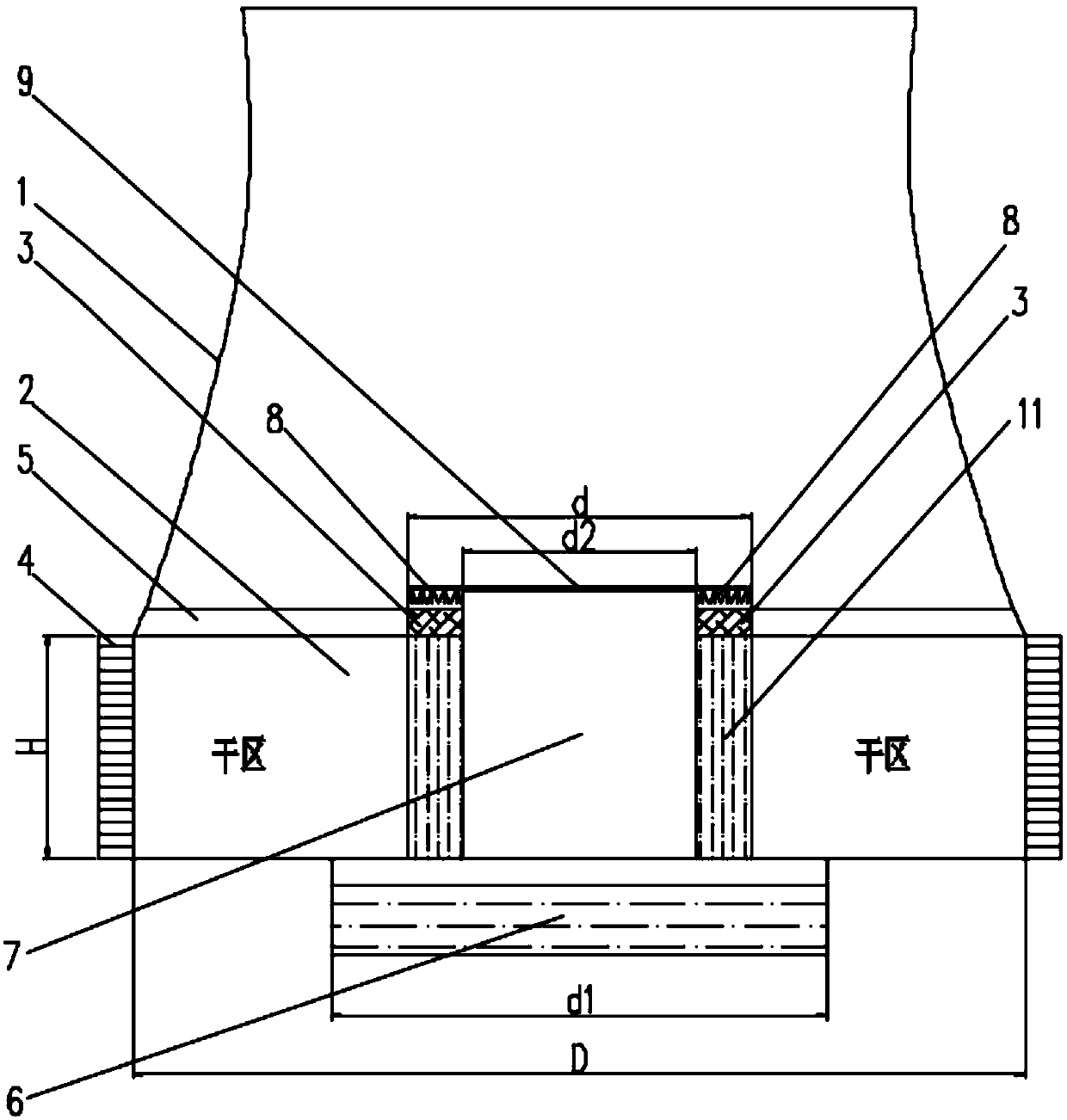

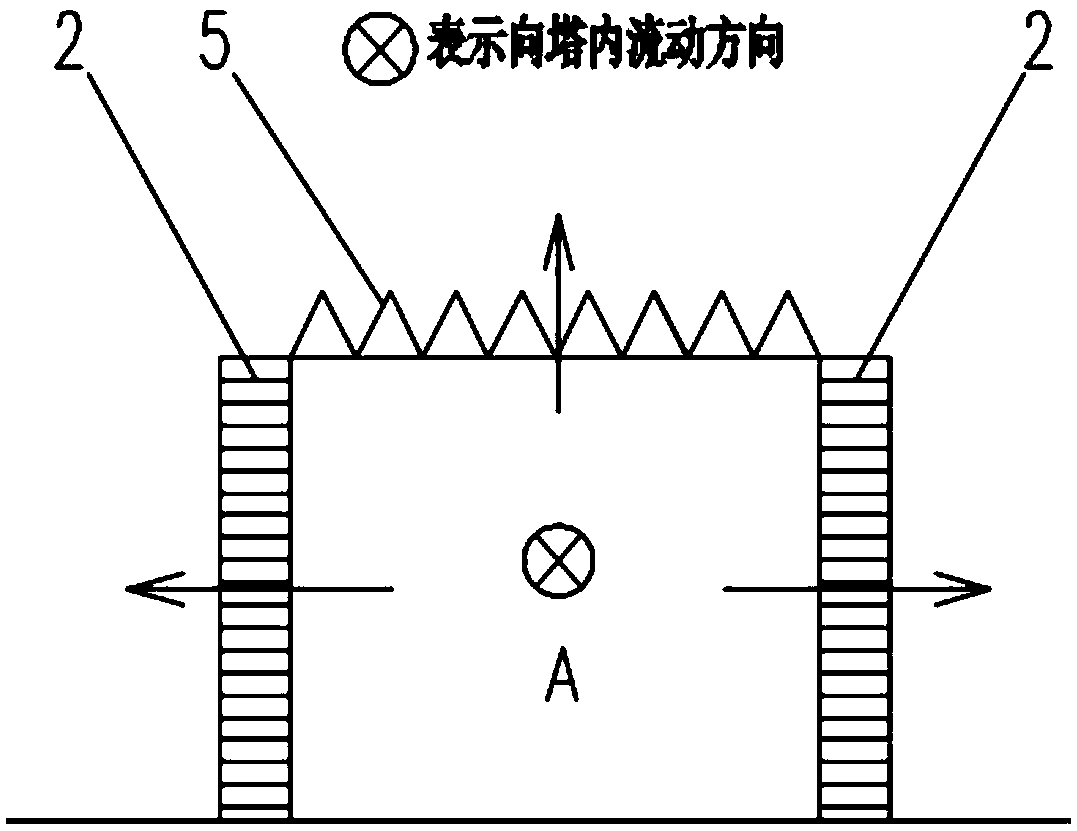

Dry-wet mixed large-scale cooling tower with continuous packing arrangement, cooling system and method

ActiveCN106610232BSimplify the cooling systemLess investmentTrickle coolersCold airNatural ventilation

The invention discloses a continuously-arranged-filler type dry-wet mixed large-sized cooling tower, a cooling system and a method for improving the cooling efficiency of the cooling tower. A wet type cooling area is arranged at the center of the bottom of a tower drum of the cooling tower. A dry type cooling area is arranged around the wet type cooling area. The dry type cooling area comprises first areas and second areas, wherein each first area and each second area are both in a sector shape. Each first area is adjacent to the corresponding second areas, and the first areas and the second areas are arranged around the wet type cooling area for a circle. The top of each first area is provided with a second cooling unit. The circumferential side of each second area is provided with an air inlet cooling unit and a first cooling unit. Air enters the first areas and / or the second areas for dry type cooling. The external cold air entering each first area and the corresponding second area flows through a group of cooling units (including the corresponding second cooling unit and the corresponding air inlet cooling unit) in the dry type cooling area from bottom to top, it can be guaranteed that air flows evenly in the dry type cooling area, and therefore the heat exchange effect in the dry type cooling area is enhanced. Because the wet type cooling area is arranged at the bottom of the inner portion of the tower drum of a dry type cooling tower, the function of a tower drum of an original small-sized natural ventilation wet type cooling tower or a tower drum of a mechanical ventilation wet type cooling tower in an existing air cooling unit system is replaced.

Owner:SHANDONG UNIV

A cooling water device for making wax models

ActiveCN110976759BImprove cooling effectPrevent splashing aroundDomestic cooling apparatusLighting and heating apparatusThermodynamicsWater leakage

The invention provides a cooling water device for making wax molds, which includes an overflow pipe, an ice box, an overflow pipe, a water inlet tank, a fan and a control panel box. The cold water tank body is arranged in a rectangular shape as a whole, and an ice cube is welded on its left end box, and the left and right ends of the bottom of the cold water tank body are symmetrically supported by four supporting legs; the tail section of the water suction pipe is bent to the left, and its through-welding is hung on the right side of the bottom plate of the cold water tank body; There are multiple leaking grooves running through the leaking plate at equal distances; a water pump is locked and fixed in the middle position of the outer wall on the left side of the ice box, and the mold frame of the present invention is set, and the mold frame is the carrier of the wax film cylinder. , it can support and place the wax film cylinder so that it is immersed in the cooling water inside the cold water tank body to implement cooling of the wax liquid inside the wax film cylinder.

Owner:宁海凯汇日用品有限公司

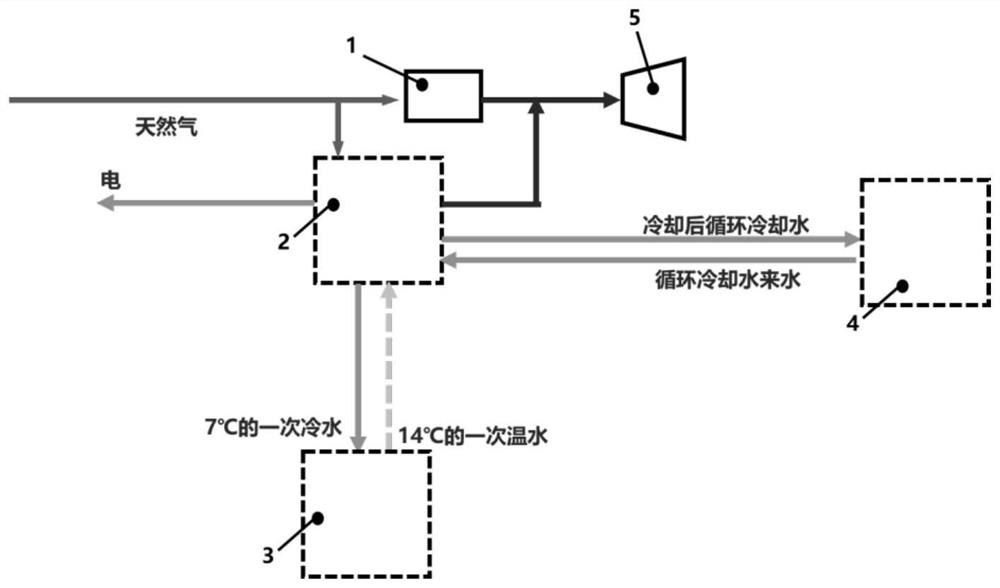

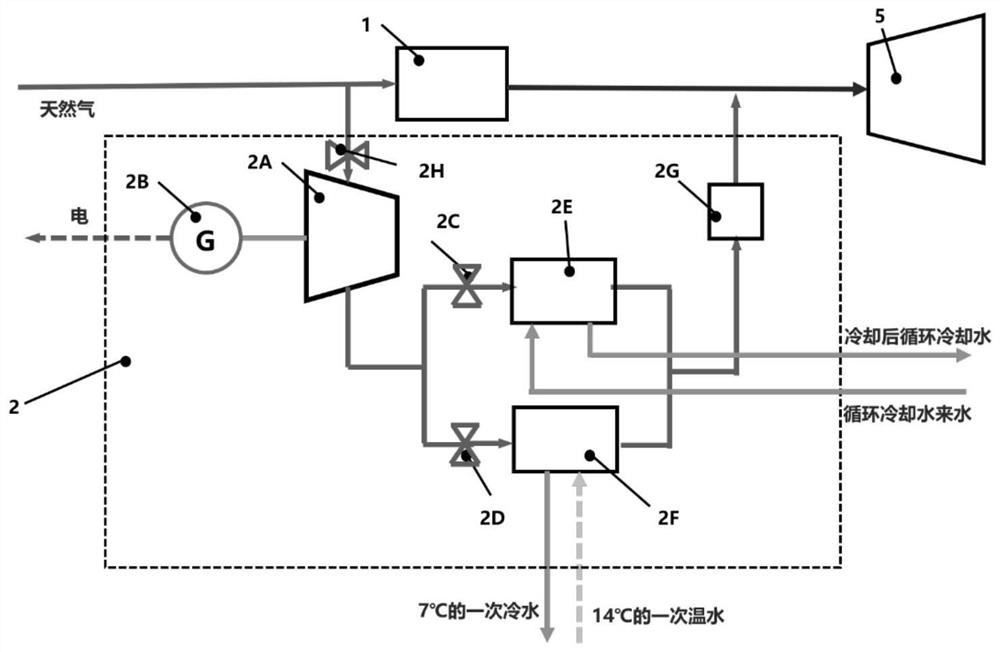

In-plant comprehensive utilization system and method for natural gas pressure energy of combined cycle power plant

PendingCN112343714AReduce back pressureHigh outputTurbine/propulsion fuel heatingSteam/vapor condensersProcess engineeringRefrigeration

The invention discloses an in-plant comprehensive utilization system and method for natural gas pressure energy of a combined cycle power plant. The system comprises a natural gas power generation / refrigeration system, an in-plant comfort cooling system, a circulating cooling water heat exchange system and a gas turbine. The natural gas power generation / refrigeration system and the gas turbine areconnected in parallel and are both connected with a natural gas pipeline. A gas outlet of the natural gas power generation / refrigeration system is connected with a gas inlet of the gas turbine. Electric energy generated by the natural gas power generation / refrigeration system is used for providing electric energy, and prepared cold water is connected with the in-plant comfort cooling system and the circulating cooling water heat exchange system. According to the system, the back pressure of a steam turbine can be reduced, the output of the steam turbine can be improved, and finally comprehensive utilization of the energy is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

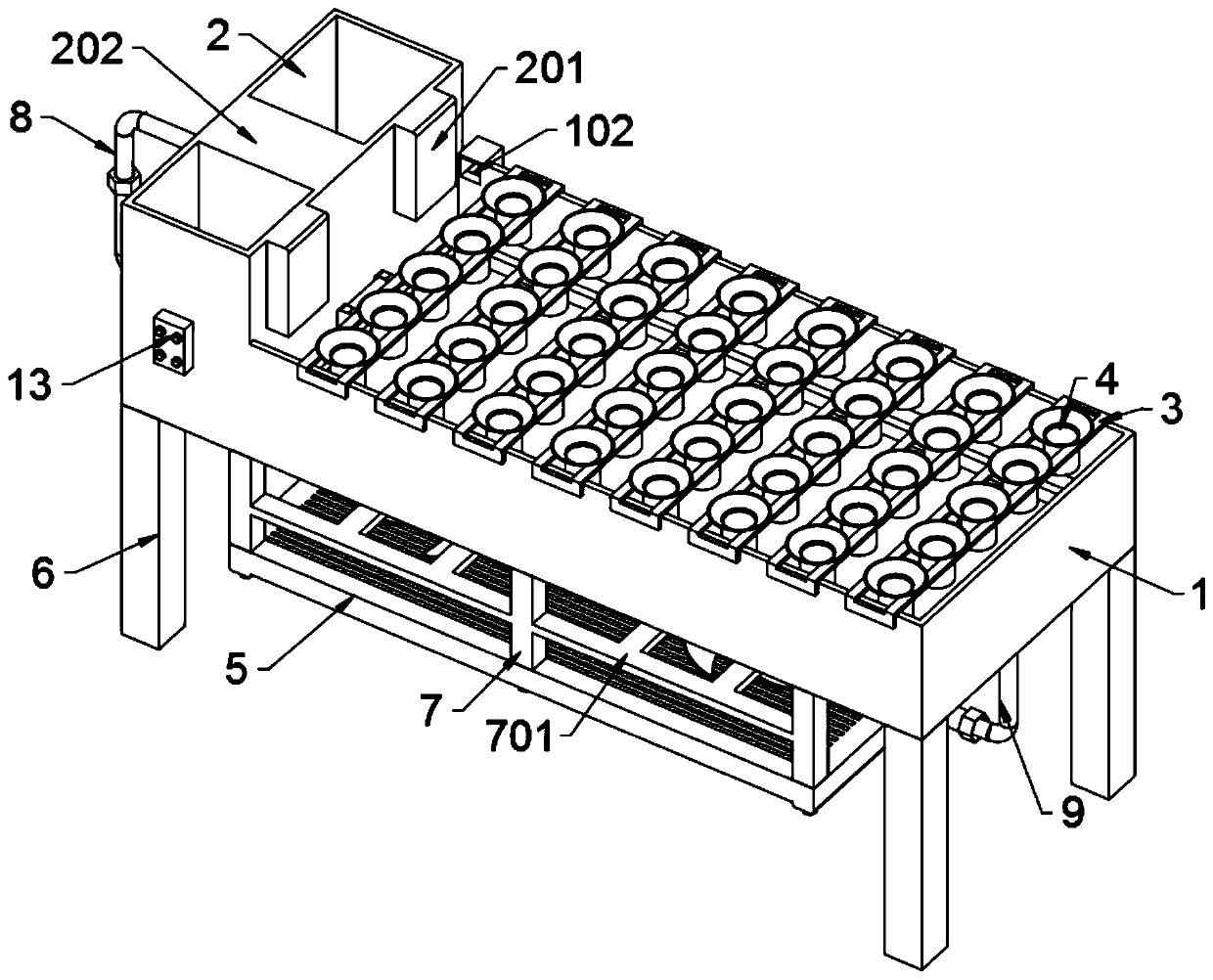

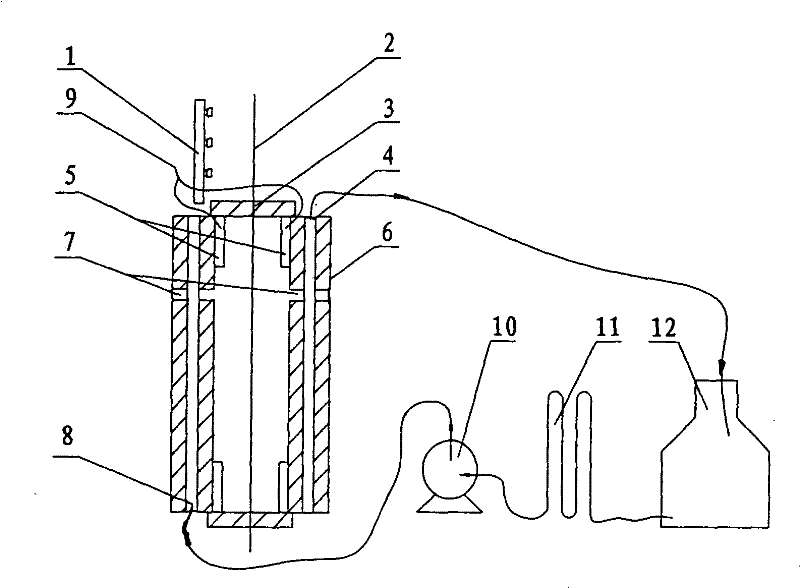

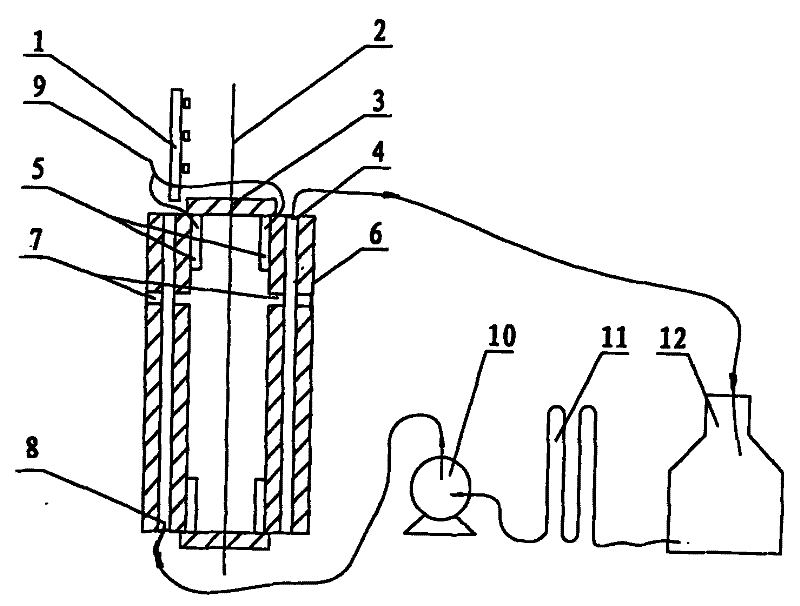

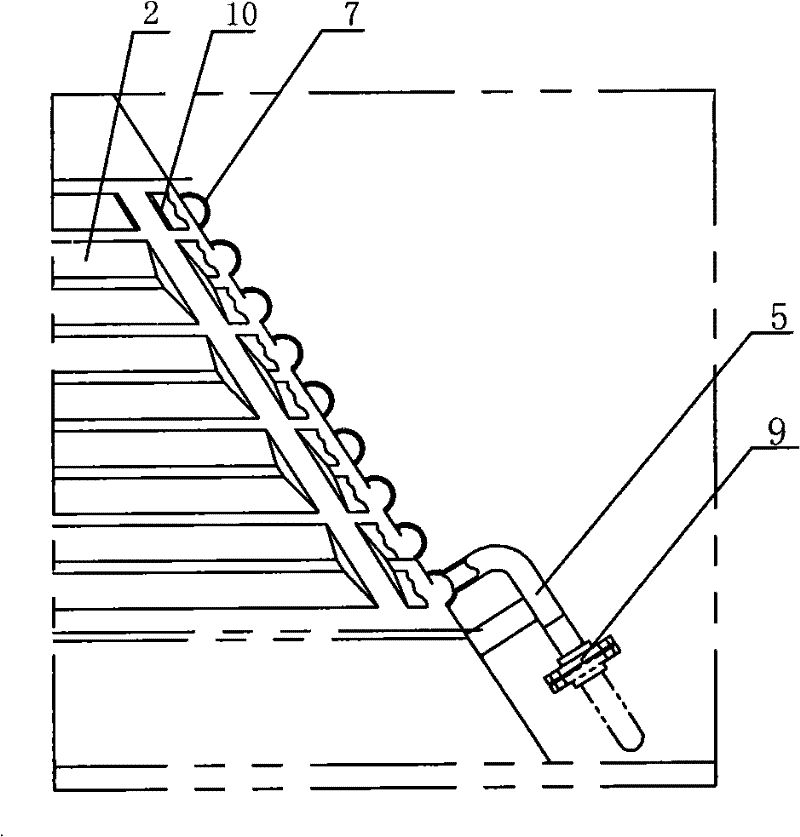

Optical fiber drawing cooling system

ActiveCN101531455BImprove cooling effectReduce whiplashGlass making apparatusGlass productionWater storage tankEngineering

The invention discloses an optical fiber drawing cooling system, and relates to a bare optical fiber cooling system in a single mode optical fiber drawing process. The optical fiber drawing cooling system is used for reducing the temperature of an optical fiber before coated, is suitable for improving the optical fiber curing performance, and ensures that the single mode optical fiber is applied to an optical fiber communication system with high speed, high capacity and long distance. A structure of the optical fiber drawing cooling system consists of an antistatic device, a cooling tube body, a cooling water pipe, a gas pipeline and a cooling water circulation device, wherein the antistatic device consists of a static eliminator and a static transferring component; the cooling tube body is provided with an inner cavity which is suitable for passing through the optical fiber, and the outside of the inner cavity is provided with the cooling water pipe and a gas injection channel of cooling gas; an upper mouth and a lower mouth of the cooling tube body are provided with drain plugs with variable apertures; the cooling water pipe is arranged on the outside of the inner cavity of the cooling tube body; the cooling water circulation device comprises a cooling water storage tank, a cooling water pump and a refrigerator; and the gas injection channel of the cooling gas is positioned on the lateral part of the cooling tube body, communicated with the inner cavity of the cooling tube body, and is distributed on the periphery of the inner cavity.

Owner:四川天府江东科技有限公司

Large-scale dry-wet mixed cooling tower with annular packing arrangement and thermal power plant cooling system

ActiveCN106643205BLow ventilation resistanceLess investmentTrickle coolersCooling towerCooling effect

The invention relates to a dry and wet blended large-scale cooling tower with filler being annularly arranged and a cooling system of a thermal power plant and belongs to the field of energy and power engineering. The cooling tower comprises a cooling tower drum. The lower side of the cooling tower drum is sequentially provided with dry area air inlet cooling units, a dry area in-tower perpendicular cooling unit, a wet area filler area and a wet area hollow area from outside to inside. A dry area in-tower horizontal cooling unit is arranged on the upper portion of the dry area in-tower perpendicular cooling unit. The top of the wet area hollow area is provided with a cover plate. The bottom of the wet area hollow area is a wet type water collecting pool. A water distributing area and the filler area of the wet area are both annular. By the adoption of the dry and wet blended large-scale cooling tower with the filler being annularly arranged, because the brand new structure is designed, through the cooling units of different structures in the dry area, the annular-structure filler area and the annular-structure water distributing area, the wind resistance is greatly lowered, the ventilation cooling effect is guaranteed, and the heat exchange performance of the wet area is improved.

Owner:SHANDONG UNIV

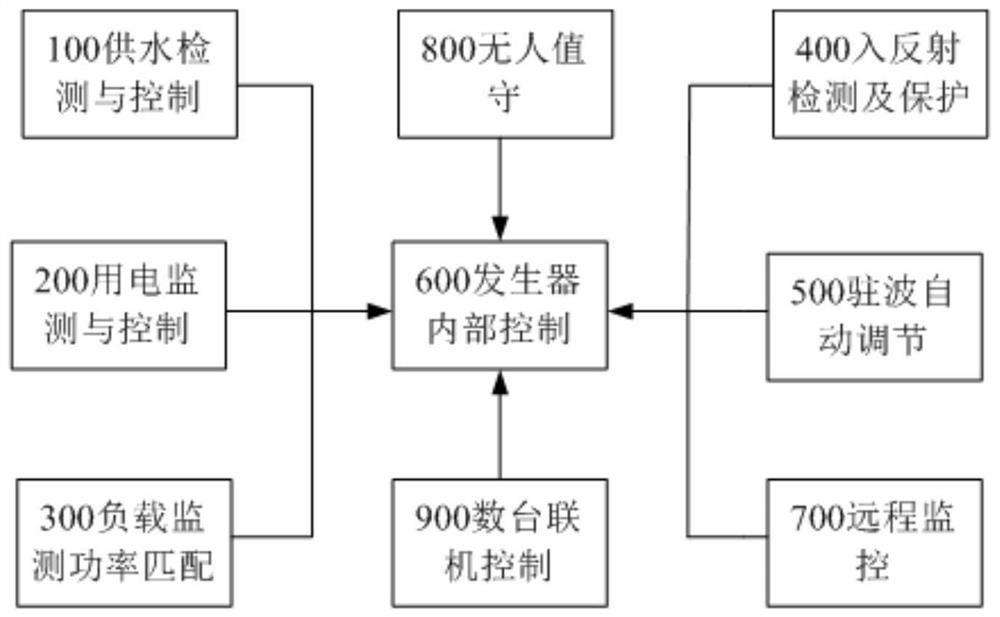

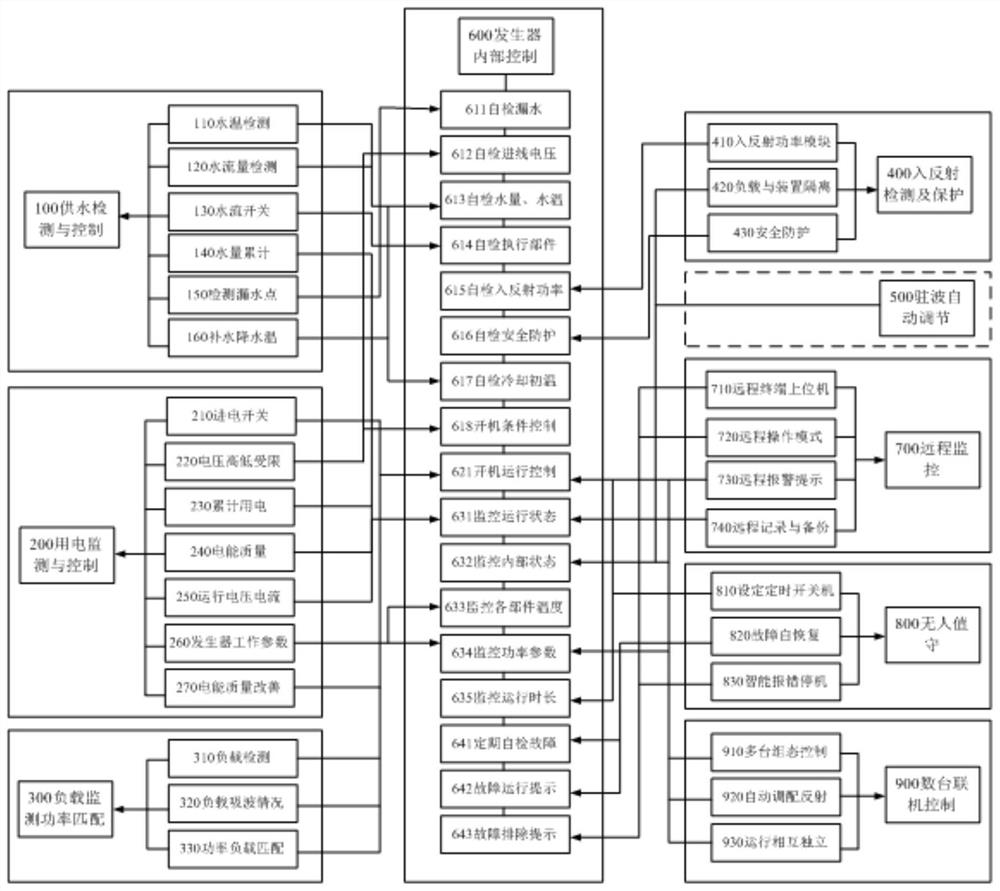

High-power intelligent microwave generator

InactiveCN113138576AFree from manual monitoringWith intelligent configurationProgramme controlMeasurement devicesMicrowave powerMonitoring and control

The invention relates to the technical field of microwave generation devices, and discloses a high-power intelligent microwave generator. The high-power intelligent microwave generator includesa microwave generator internal control module, a water supply detection and control module, a power utilization monitoring and control module, a load monitoring power matching module, an incoming reflection detection and protection module, a standing wave automatic adjustment module, a remote monitoring module, an unattended module and a plurality of online control modules. According to the high-power intelligent microwave generator, the disadvantages of an existing microwave generator are comprehensively complemented, so that the functions of the microwave generator are more diversified, the whole microwave generator is more intelligent, and the problems that an existing micronized wave generator does not have effective water supply detection, operation conditions cannot be detected, and power supply cannot be limited and the electric quantity cannot be controlled due to the lack of power utilization monitoring, matching automation of a load and microwave power is poor, incident reflection power cannot be effectively detected and protected, the functions of standing wave automatic adjustment and generator remote monitoring are lacked, and unattended intelligent industrial requirements cannot be met are solved.

Owner:NANJING SANLE MICROWAVE TECH DEV +1

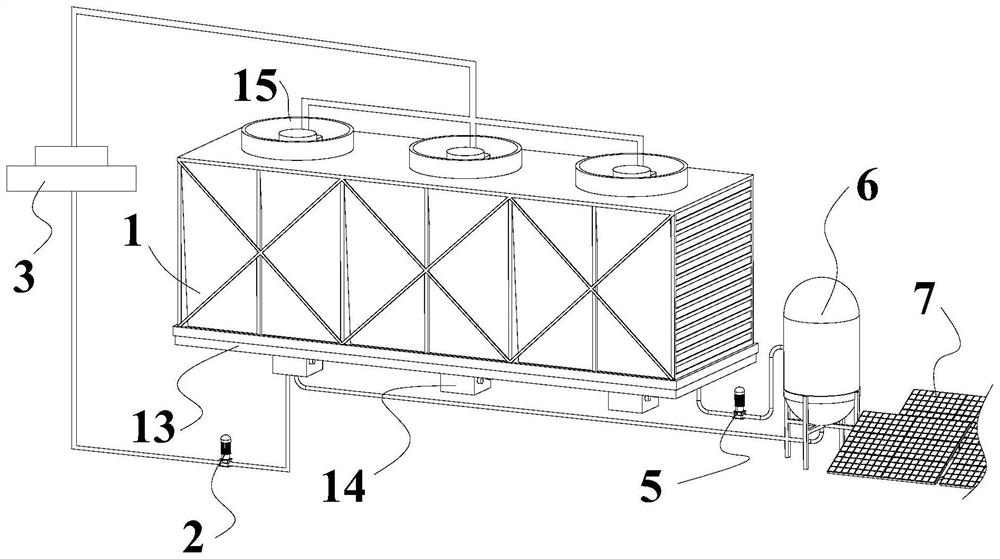

An optimized power tower with single side air intake

ActiveCN108592650BImprove heat transfer effectIncreased flow distanceTrickle coolersMarine engineeringCooling effect

The invention discloses an optimized single-side air inlet induced draft tower. The induced draft tower comprises a tower body, fans and padding. An air inlet is formed in the tower body. The paddingis divided into a windward side padding body and a leeward side padding body. The distance between the center lines of the fans and the windward side inner wall surface of the tower body is B3, and the distance between the center lines of the fans and the leeward side inner wall surface of the tower body is B4 (please see the ratio of B3 to B4 in the specification). By optimizing the parameters such as the fan arrangement position, the height of the air inlet, the height and width of the padding and the water spraying density, the inlet air dead zone is reduced, and the inlet air in the toweris optimized; and the cooling effect of a rain area and the padding in the tower is fully utilized, so that the cooling performance of the entire induced draft tower is improved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

Furnace cap water-cooling device for converter

InactiveCN101812565BPromote circulationLower the cooling water temperatureManufacturing convertersProcess efficiency improvementSlagCooling effect

The invention relates to a furnace cap water-cooling device for a converter and belongs to the technical field of auxiliary devices of a converter. The furnace cap water-cooling device for the converter comprises a steel tube arranged on the outer surface of the furnace cap; the steel tube is divided into at least three sections along the circumference of the furnace cap; the sections of the steel tube are arranged in a snake shape at intervals along the outer surface of the furnace cap and are provided with a gap for accommodating a slag-blocking skirt support plate respectively; and head and tail ends of each section of the steel tube are connected with a water inlet pipe and a water outlet pipe respectively. The cooling water in each section of the steel tube of the furnace cap water-cooling device for the converter only densely flows through a smaller region of the outer surface of the furnace cap, so that the circulation of the cooling water is accelerated, the area covering the outer surface of the furnace cap is increased, and the water temperature is reduced. Therefore, the cooling effect of the furnace cap is greatly improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A kind of thinner polyolefin shrink film and its production process

ActiveCN110303748BHigh strengthGood heat sealingSynthetic resin layered productsFlat articlesLinear low-density polyethylenePolymer science

The invention discloses a relatively thin polyolefin shrink film and its production process. The present invention adopts the raw materials of the inner and outer layers and the raw materials of the middle layer to be prepared through a secondary inflation process, wherein the raw materials of the inner and outer layers are: ternary random copolymer polypropylene, anti-sticking agent and smooth agent; the middle layer The raw materials are: eight-carbon linear low-density polyethylene, metallocene LLDPE and slip agent. The present invention reduces the thickness of the film through formulation and process adjustment, making it easier for the second bubbles to form bubbles, and the physical and mechanical properties of the POF film are not lower than 10 μm in all aspects, and overcome the thinner the film, the lower the heat sealing performance, and During the slitting process, it is easy to pleat and slitting is difficult.

Owner:山东联众包装科技有限公司

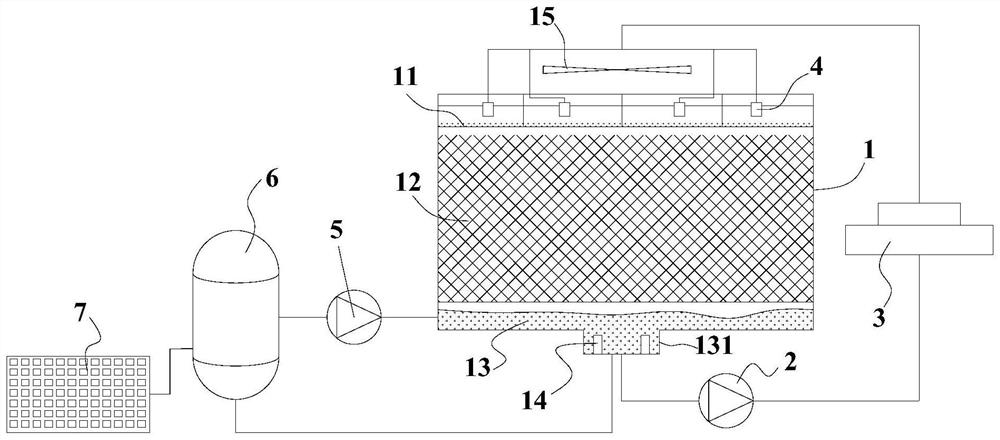

Evaporative condenser heat pump air-conditioning unit

InactiveCN102620371BWide range of operationsLow running costSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringMechanics

The invention discloses an evaporative condenser heat pump air-conditioning unit, which comprises a condenser, and the condenser comprises a housing, a solution pump, an automatic doser, a water-collecting tray, heat-dissipating filling, an evaporator coil, water nozzles and a fan; the fan, the water nozzles, the evaporator coil, the heat-dissipating filling and the water-collecting tray are arranged sequentially from the top down in the housing, and the lower part of the housing is provided with an air inlet between the water-collecting tray and the heat-dissipating filling; one end of the evaporator coil is connected with the end b of a four-way reversing valve, and the other end of the evaporator coil is connected with one end of an evaporator through a thermal expansion valve and a first one-way valve; the water inlet of the solution pump is connected with the water-collecting tray, and the water outlet of the solution pump is connected with the water nozzles; and the automatic doser is connected in parallel with the solution pump. The invention overcomes the defects of conventional air source heat pumps supplying heat in winter in damp, cold regions with a run of wet weather and high air humidity, i.e. severe frosting, demand for defrosting and low heat pump efficiency; meanwhile, the evaporative condenser heat pump air-conditioning unit is not limited by geological conditions, the cost is low, and the energy efficiency is high.

Owner:ANHUI JINGAO REFRIGERATION EQUIP

Dry-wet mixing large-scale cooling tower with petal-shaped packing arrangement, cooling system and method

ActiveCN106766990BSimplify the cooling systemLess investmentTrickle coolersCooling towerCooling effect

A large-sized mixed wet-and-dry cooling tower having a filler in a petal-like arrangement, a cooling system and a method. Air from a first area (A) and that from a second area (B) in the cooling tower entering a wet cooling area are of different temperatures, thus forming a temperature difference in the wet cooling area. The petal-like arrangement of the filler in the wet cooling area enhances airflow in the wet cooling area and increases cooling effects of the wet cooling area. By arranging the wet cooling area at the inner tower bottom of a dry cooling tower as a substitute for the function of an existing miniature naturally ventilated wet cooling tower or that of a mechanically ventilated wet cooling tower in an existing air-cooled unit system, the cooling system for an air-cooled unit is simplified, thus reducing equipment investment.

Owner:SHANDONG UNIV

Heat preservation type cooling system

PendingCN114593614APrevent dry burningImprove securityEvaporators/condensersEnergy industryHeat conservationEnvironmental geology

The invention discloses a heat preservation type cooling system which comprises a cooling tower, a water pump, a water chilling unit, a circulating water pump, a heat storage water tank and a solar panel. A water distribution disc, a filler and a water collection disc are arranged in the cooling tower from top to bottom, the water collection disc, the water pump and the water chilling unit are sequentially communicated through pipelines, and the water outlet end of the water chilling unit leads to the water distribution disc; a groove is formed in the water collecting tray, and a heating device is arranged in the groove; the circulating water pump, the heat storage water tank and the water collecting tray are communicated through pipelines, a water tank heating device is arranged in the heat storage water tank, and the solar panel is connected to the water tank heating device. The method has the advantage that the defects of long heating time, potential safety hazards and the like are overcome.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Multistage evaporating process in viscose production

ActiveCN102100973BTake advantage ofImprove evaporation efficiencyEvaporationWater useProcess engineering

The invention relates to a multistage evaporating process in viscose production, which comprises the steps of acid bath heating, acid bath evaporating, secondary steam recycling and exhausting, condensed water discharging, incoagulable gas exhausting and the like. Aiming at the prior art, equipment and a process route are re-designed, secondary steam is recycled, the heat which is not utilized in the prior art is fully utilized, so that the purpose of improving the yield is achieved, the zero emission of evaporating water is realized, and a large quantity of sewage treatment cost and clear water supply and discharge costs are saved.

Owner:CHENGDU GRACE FIBER +1

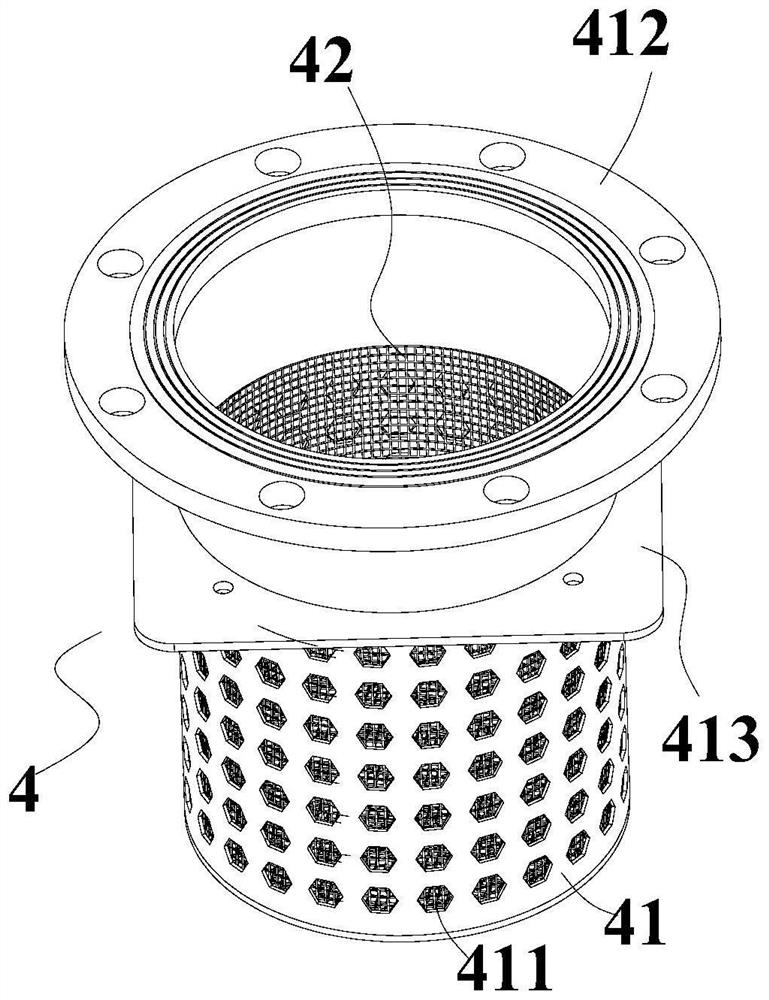

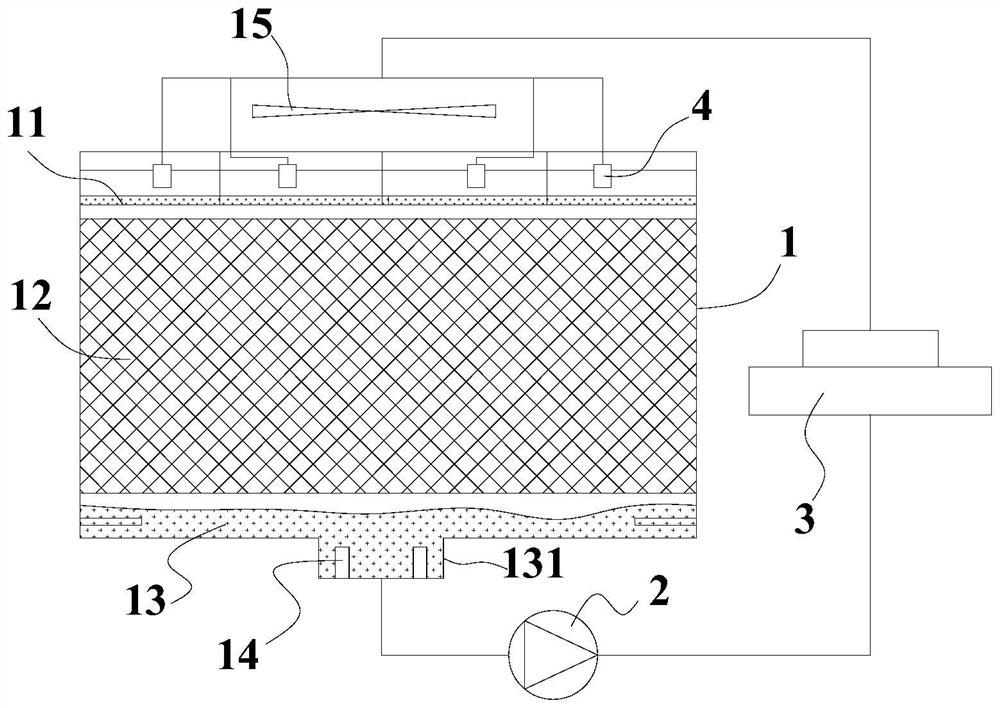

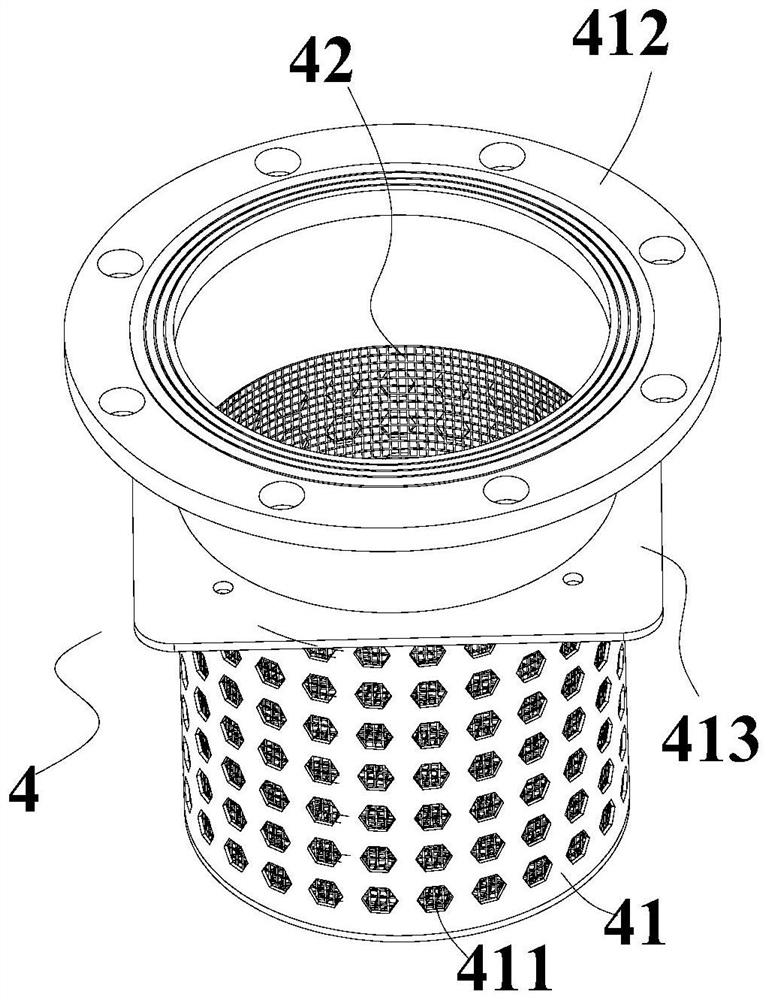

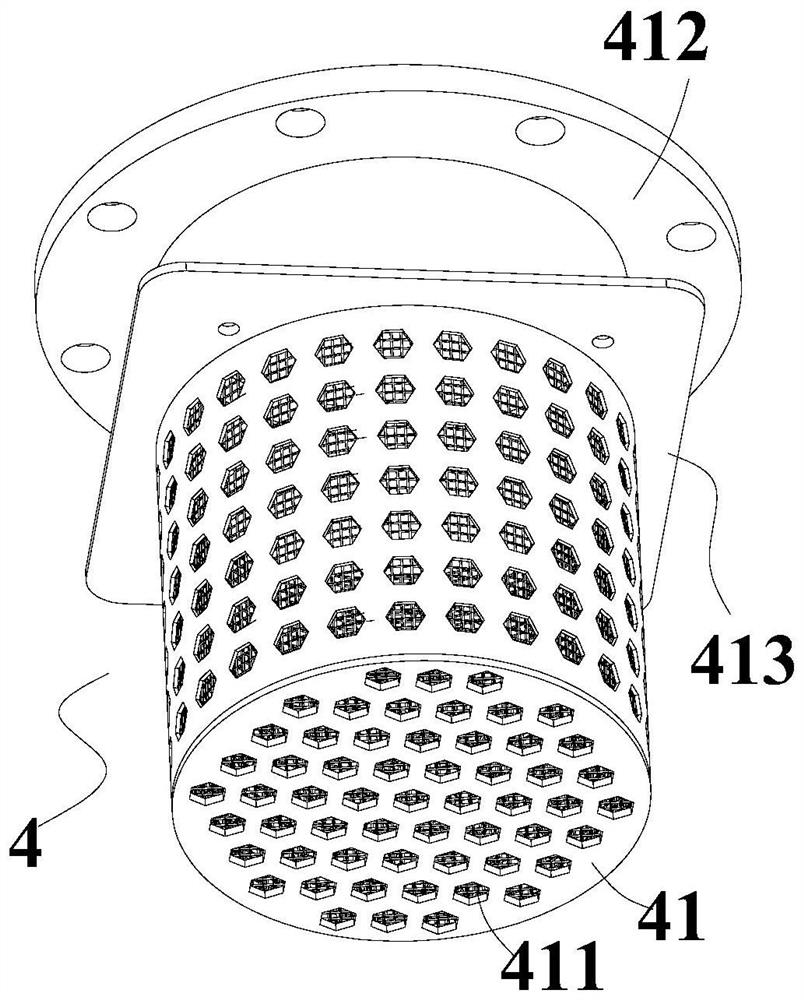

Cooling system with energy-consuming bubbler

The invention discloses a cooling system with an energy-consuming bubbler. The cooling system comprises a cooling tower, a water pump, a water chilling unit and the energy-consuming bubbler, the cooling tower is internally provided with a water distribution disc, a filler and a water collection disc from top to bottom, and the water collection disc, the water pump, the water chilling unit and the energy-consuming bubbler are sequentially communicated through a pipeline; the energy-consuming bubbler is located above the water distribution disc and comprises an energy-consuming barrel and a bubbling net located in the energy-consuming barrel, and water from the water chilling unit flows to the bubbling net through a pipeline and flows into the water distribution disc through the energy-consuming barrel. The device has the advantages that the cooling water flow impact can be reduced to the safety degree, it is guaranteed that cooling water does not overflow out of the tower, and stable operation of a water chilling unit is guaranteed.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Multifunctional heat pump air-conditioning system

InactiveCN101949616BLarge storageReduce energy consumptionEnergy recovery in ventilation and heatingSpace heating and ventilation detailsAir conditioningThermal water

The invention discloses a multifunctional heat pump air-conditioning system which comprises a compressor, a heat recovery device, a condenser and a throttling valve, wherein an evaporator water side outlet is communicated with a circulating pump inlet by a valve; a circulating pump outlet is communicated with an indoor tail end pipe network; an indoor tail end pipe network outlet is communicated with an evaporator water side inlet by a valve; a heat recovery device water side outlet is communicated with a hot-water circulating pump inlet pipe by a valve; a hot-water circulating pump outlet iscommunicated with a hot-water tank inlet, and a hot-water tank outlet pipe is communicated with a heat recovery device hot-water side inlet by a valve; a condenser water side outlet is communicated with a solution circulating pump inlet by a valve; a solution circulating pump outlet is communicated with an energy tower inlet; an energy tower outlet is communicated with a condenser water side inlet by a valve; a condenser water side outlet is communicated with the hot-water circulating pump inlet pipe by a valve; and the condenser water side inlet is communicated with the hot-water tank outletpipe by a valve. The invention has the advantages of energy saving and environmental protection.

Owner:郑州中南科莱空调设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com