Nitrogen yield increasing method for use in air separation unit

An air separation and nitrogen technology, which is applied in liquefaction, solidification, lighting and heating equipment, etc., can solve problems such as affecting the production capacity of the air separation plant, increasing the adsorption burden of the molecular sieve adsorber 4, and affecting the air cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

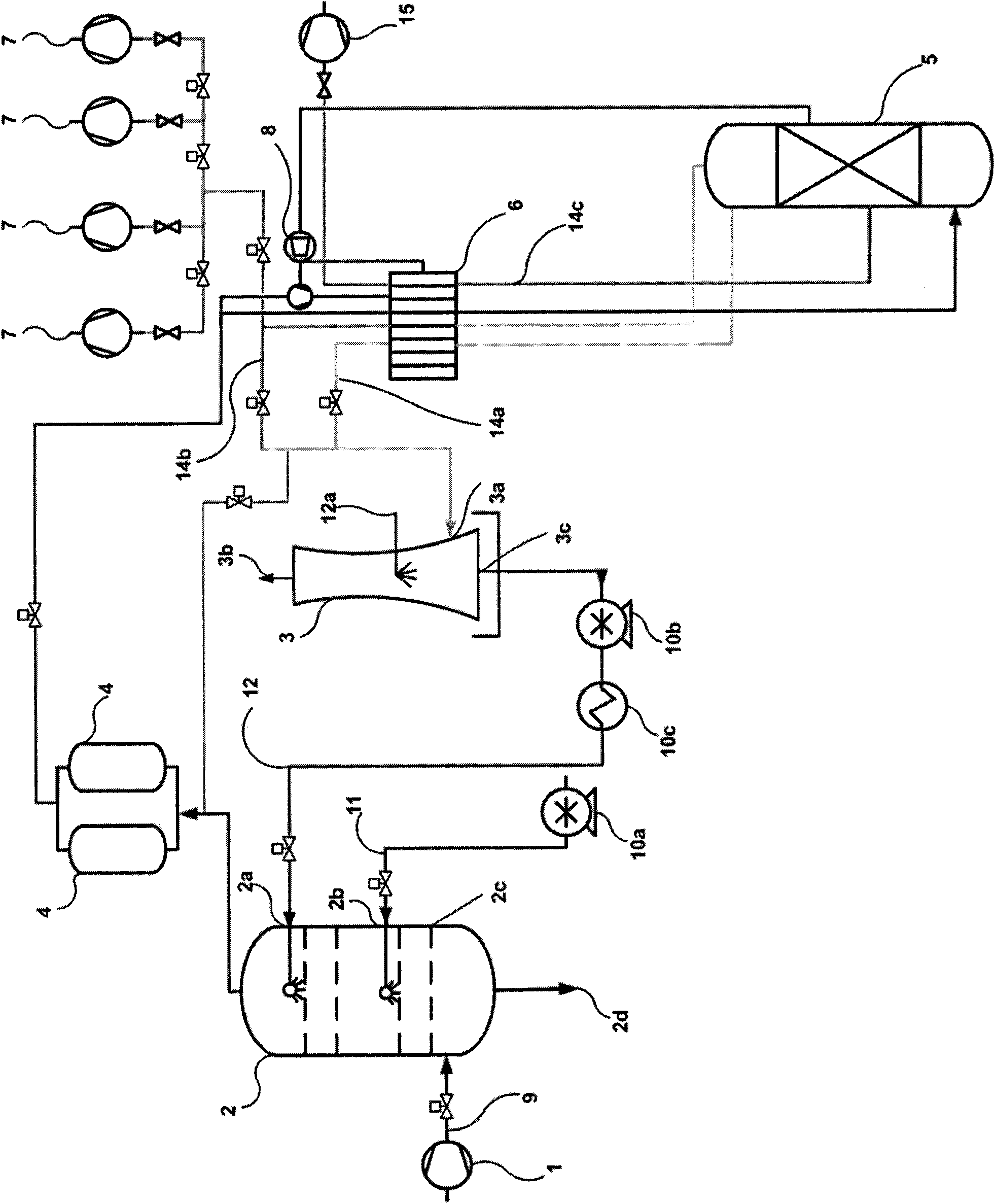

Method used

Image

Examples

Embodiment Construction

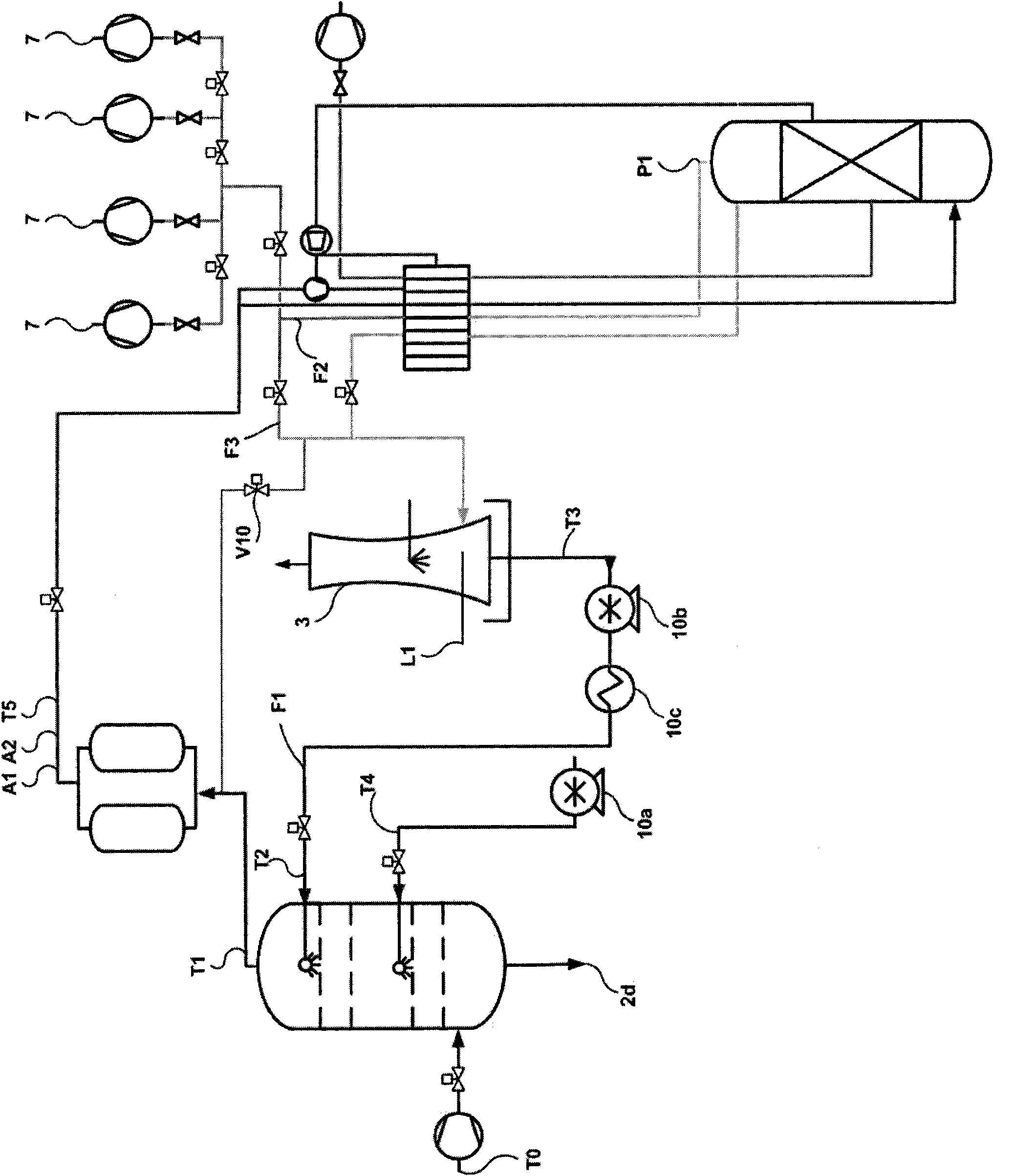

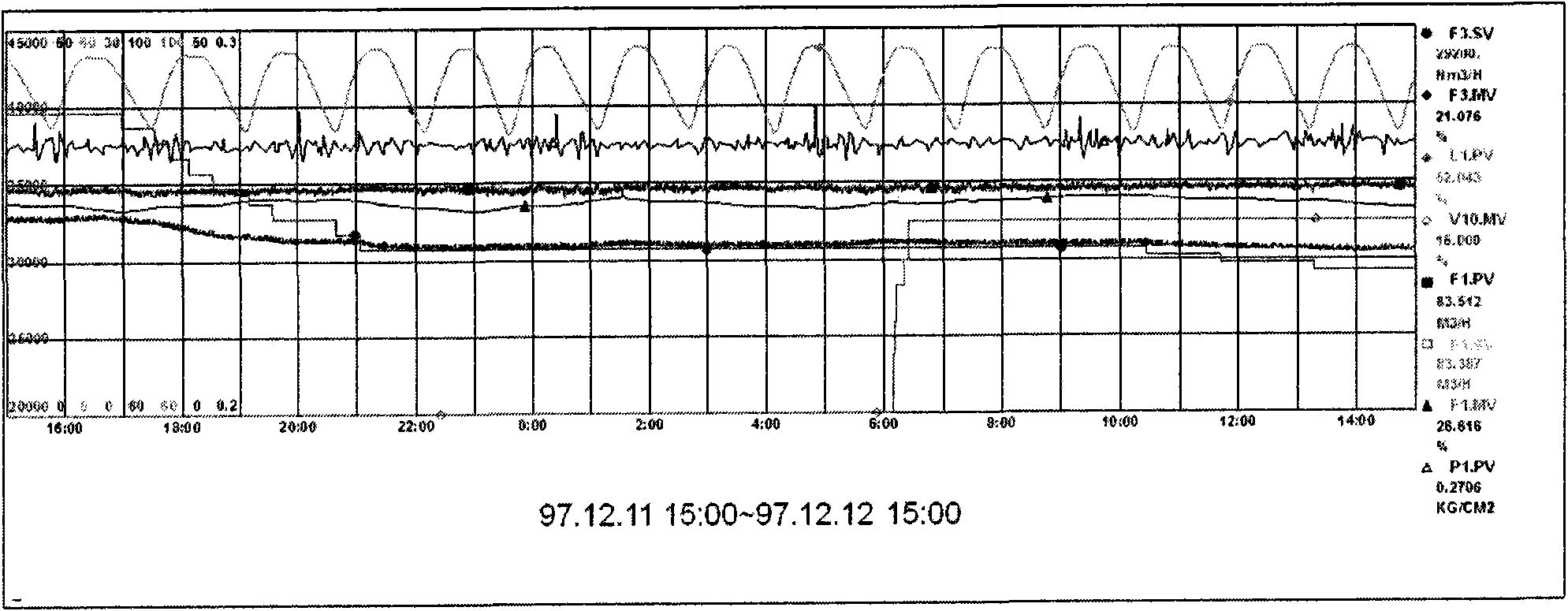

[0044] refer to figure 2 As shown, it reveals the schematic diagram of the monitoring parameters of the air separation unit of the implementation example of the present invention, which includes: the air temperature T0 entering the air compressor 1, the air temperature T1 exiting the SC air cooling tower 2, the temperature T2 of chilled water, and the temperature T2 exiting the EC The water temperature T3 of the water cooling tower 3, the water temperature T4 of the SC air cooling tower 2, the temperature T5 of the air exiting the molecular sieve adsorber 4, the CO of the air exiting the molecular sieve adsorber 4 2 Value A1, H of air out of molecular sieve adsorber 4 2 O value A2, chilled water flow rate F1, the total amount of nitrogen gas in the upper tower of the fractionation tower 5 F2, the nitrogen flow rate F3 to the EC water cooling tower 3, the pressure P1 of the upper tower of the fractionation tower, the liquid level value L1 of the EC water cooling tower 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com