Furnace cap water-cooling device for converter

A technology of water cooling device and furnace cap, applied in the field of water cooling device and water cooling device of converter furnace cap, can solve the problems of uneven distribution of angle steel, long water temperature, poor cooling effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

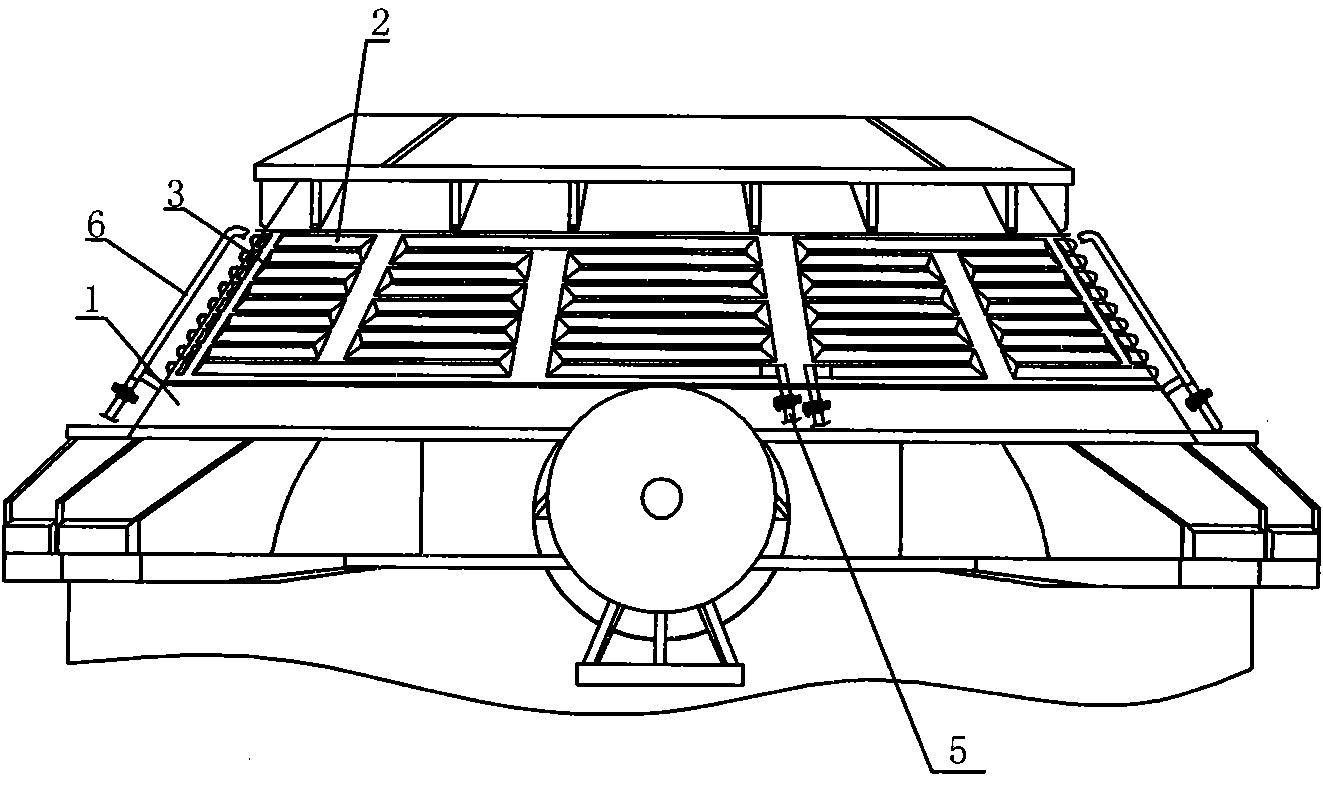

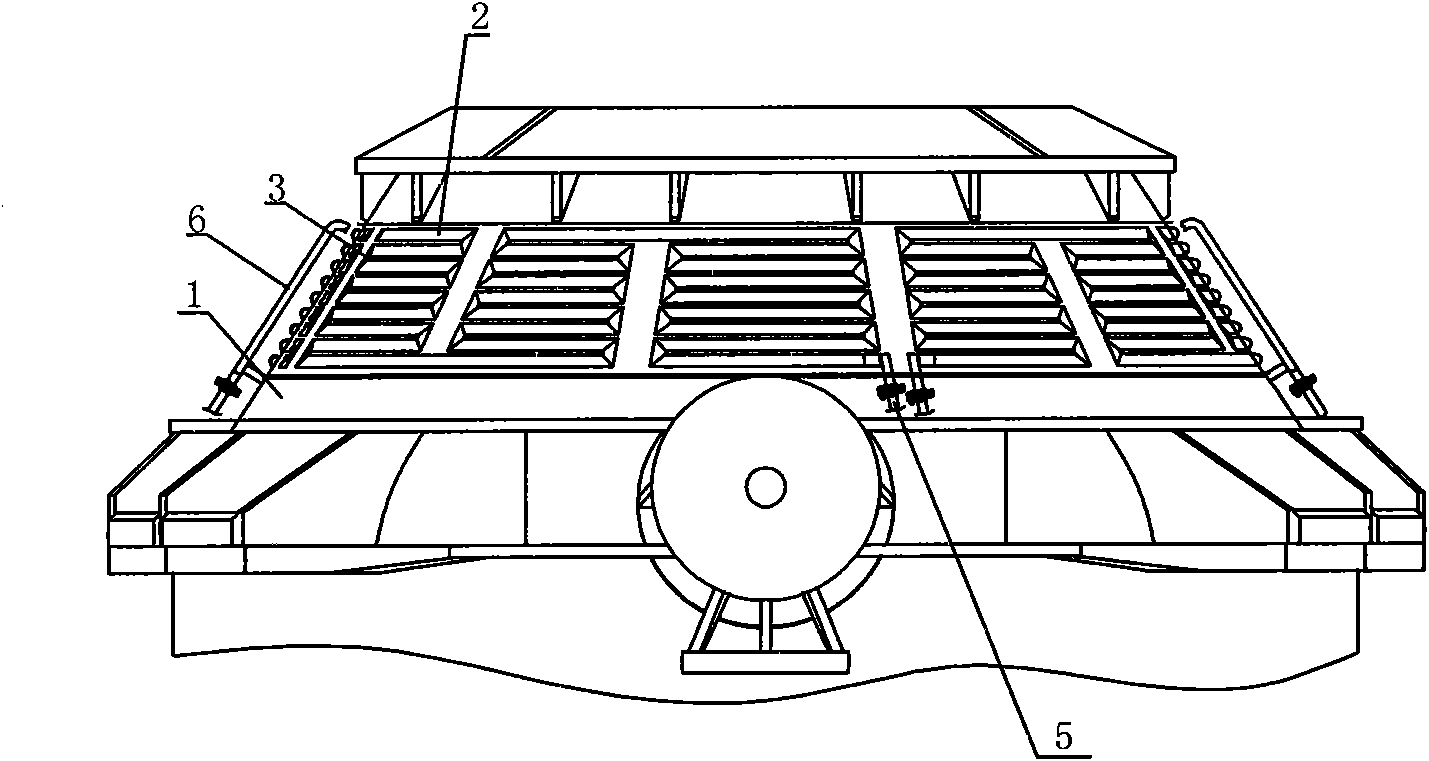

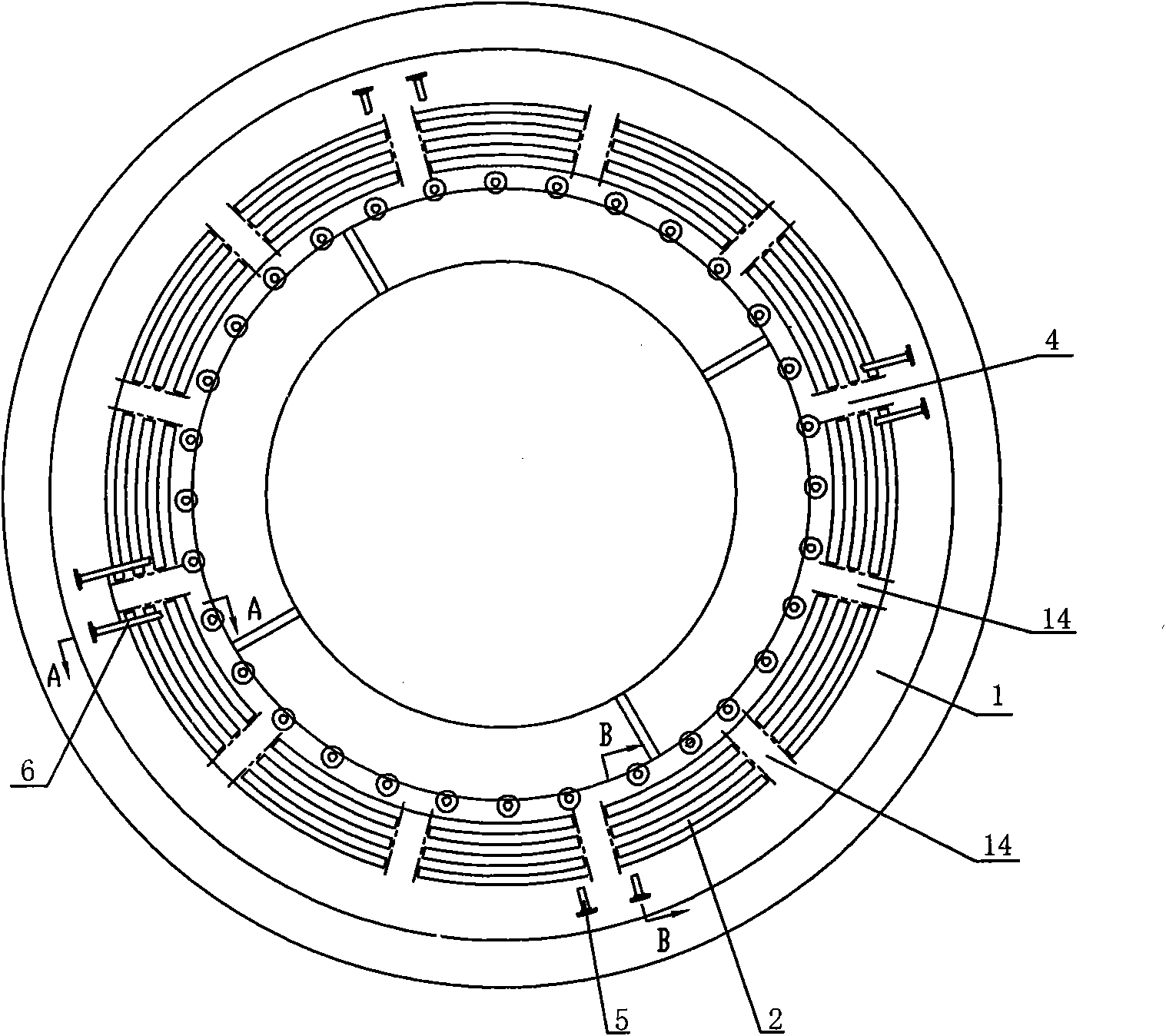

[0016] The converter cap water cooling device of this embodiment is shown in Fig. 1 and Fig. 2, and includes a steel pipe arranged on the outer surface of the furnace cap 1, and the steel pipe is divided into four sections along the circumferential direction of the furnace cap 1. Between each section of steel pipes and in each section of steel pipes, there is a gap for installing the slag retaining skirt support plate, and the gap includes a first gap 4 between each section of steel pipes and two first gaps 4 in each section of steel pipes The second neutral gear is 14, and the total number of neutral gears is 12. Each section of steel pipe is composed of horizontal steel pipes 2 welded on the outer surface of furnace cap 1 at intervals up and down and vertical steel pipes 3 connected to the same end of adjacent horizontal steel pipes 2 . The horizontal steel pipes 2 alternately communicate with each other between the uppermost end and the lowermost end of the two second gaps ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com