Dry-wet mixing large-scale cooling tower with petal-shaped packing arrangement, cooling system and method

A cooling tower and petal-shaped technology, which is applied in the field of energy and power engineering, can solve the problems of heavy maintenance workload, large floor space, complex system, etc., and achieve the effects of reducing equipment investment, reducing ventilation resistance, and simplifying the cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

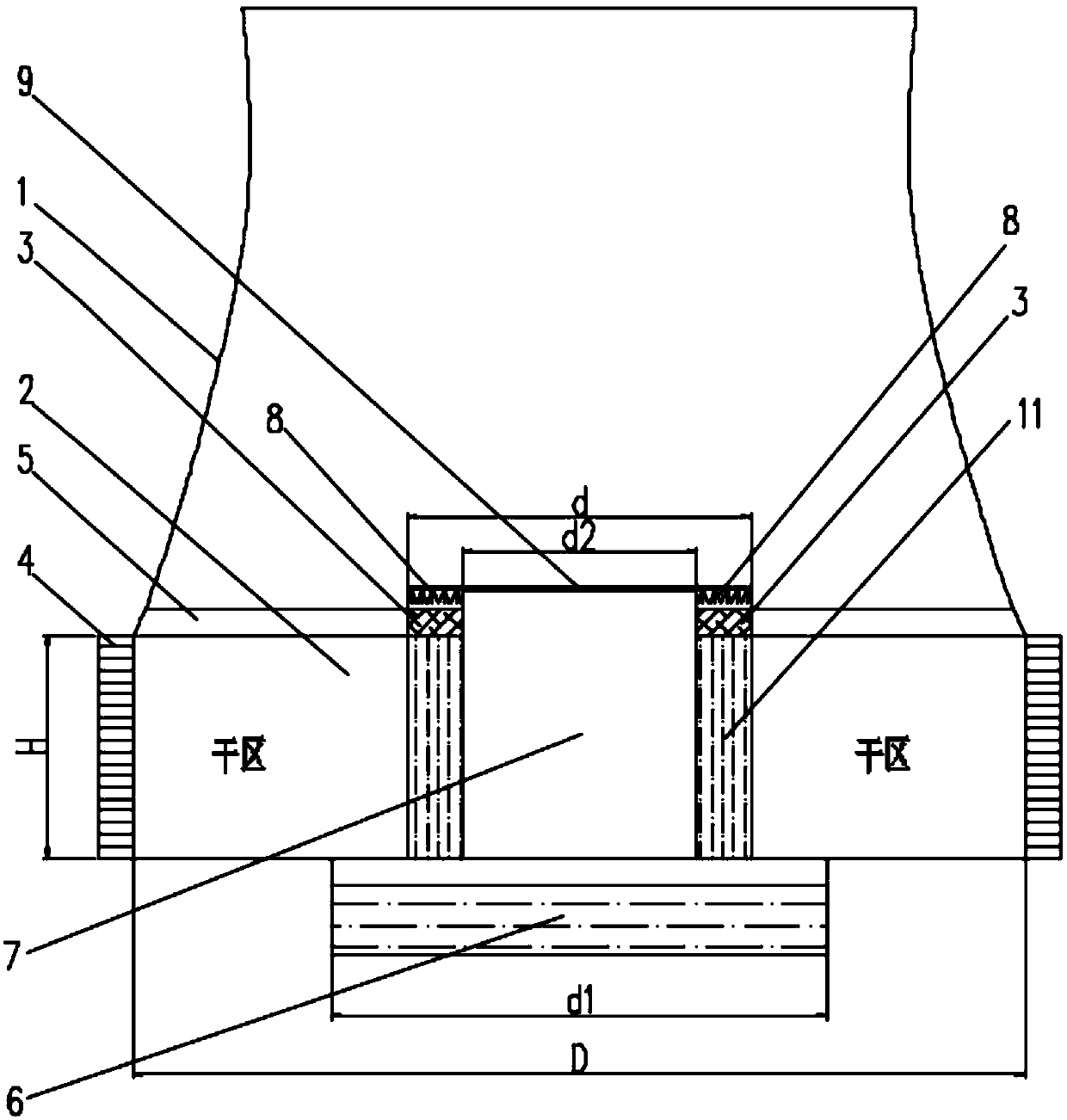

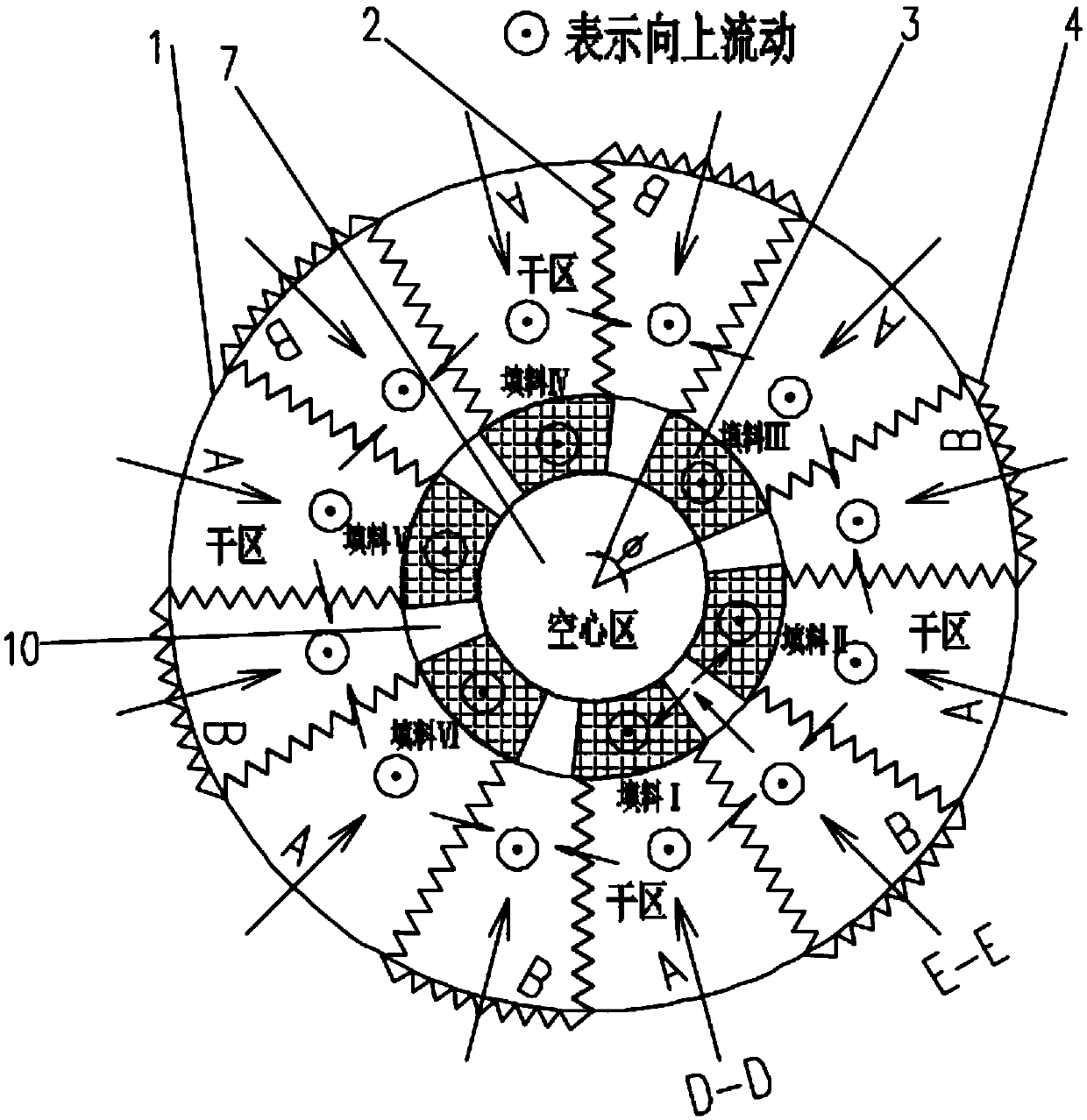

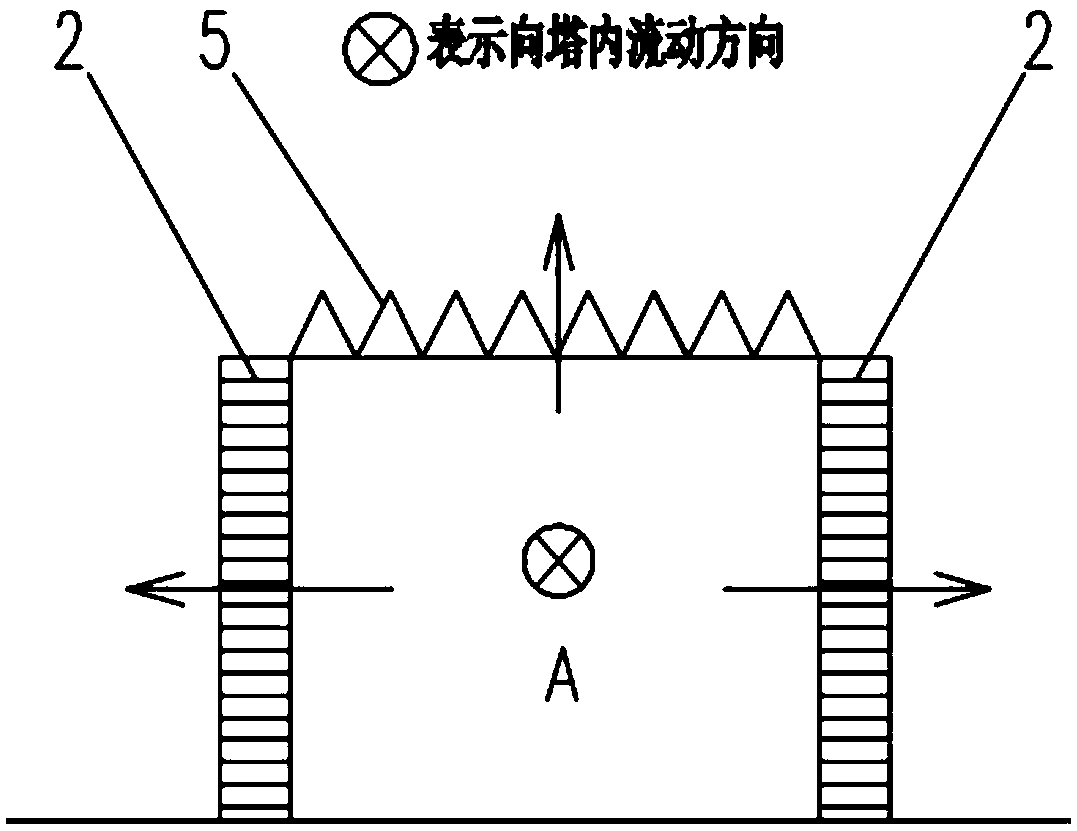

[0043] Such as figure 1 and figure 2 As shown, the dry-wet mixing large-scale cooling tower with petal-shaped packing arrangement, the center of the bottom of the cooling tower tube 1 is a wet cooling zone, and the surrounding direction of the wet cooling zone is a dry cooling zone, and the dry cooling zone includes fan-shaped first One area A and the second area B, the first area and the second area are provided with a plurality, the first area and the second area are adjacent to each other and set up a circle around the wet cooling area, and the periphery of the second area is provided with a first cooling system. Unit 2 and the air inlet cooling unit 4 located at the air inlet of the second area, the air inlet of the second area is located on the peripheral side of the second area, the first area A and the second area B share the vertical cooling unit, and the air enters the first Zone A and / or the second zone B perform dry cooling, and the air entering the wet cooling zo...

Embodiment 2

[0057] A cooling system of a thermal power plant. A cooling tower is installed in the cooling system. The cooling tower is a dry-wet mixing large-scale cooling tower arranged with petal-shaped fillers, which effectively improves the heat exchange effect of the cooling tower.

Embodiment 3

[0059] A method for improving the cooling efficiency of a cooling tower, using the dry-wet mixing large-scale cooling tower with petal-shaped packing arrangement described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com