Dry and wet blended large-scale cooling tower with filler being annularly arranged and cooling system of thermal power plant

A cooling tower, dry and wet technology, applied in the direction of water shower cooler, heat exchanger type, lighting and heating equipment, etc. Thermal effect, the effect of reducing cooling water temperature and enhancing heat exchange effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

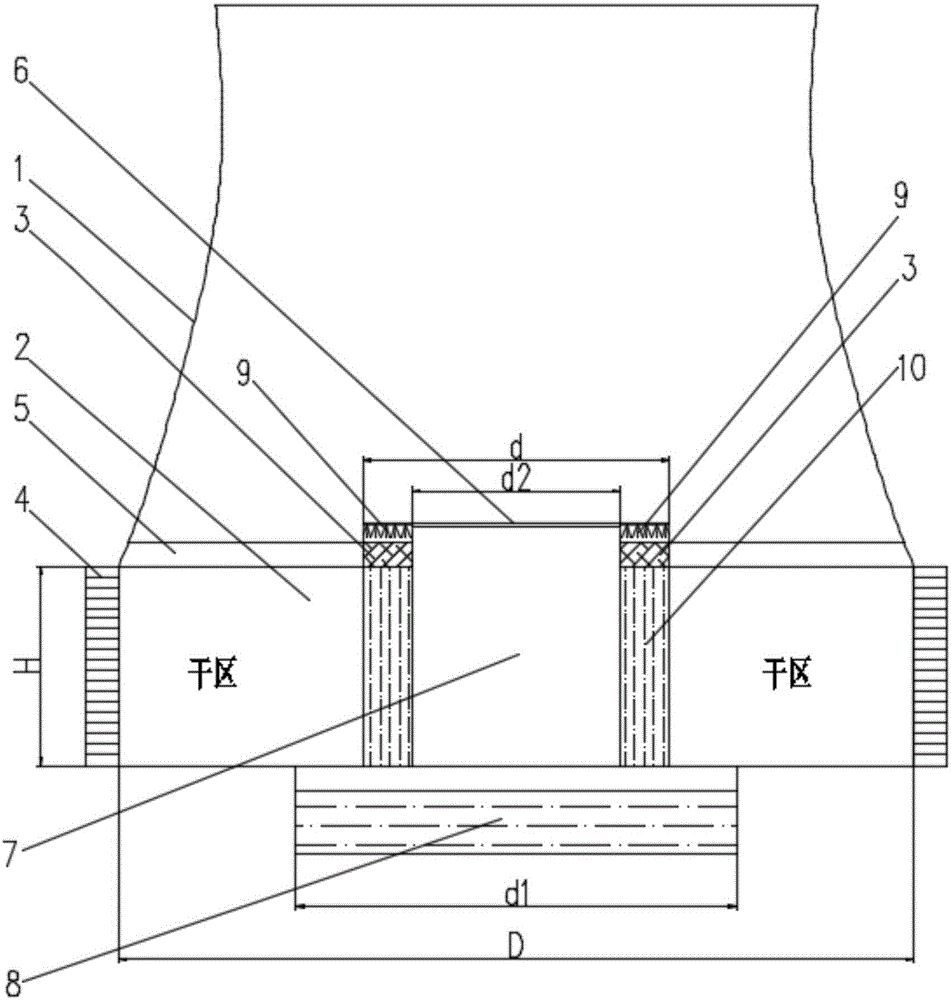

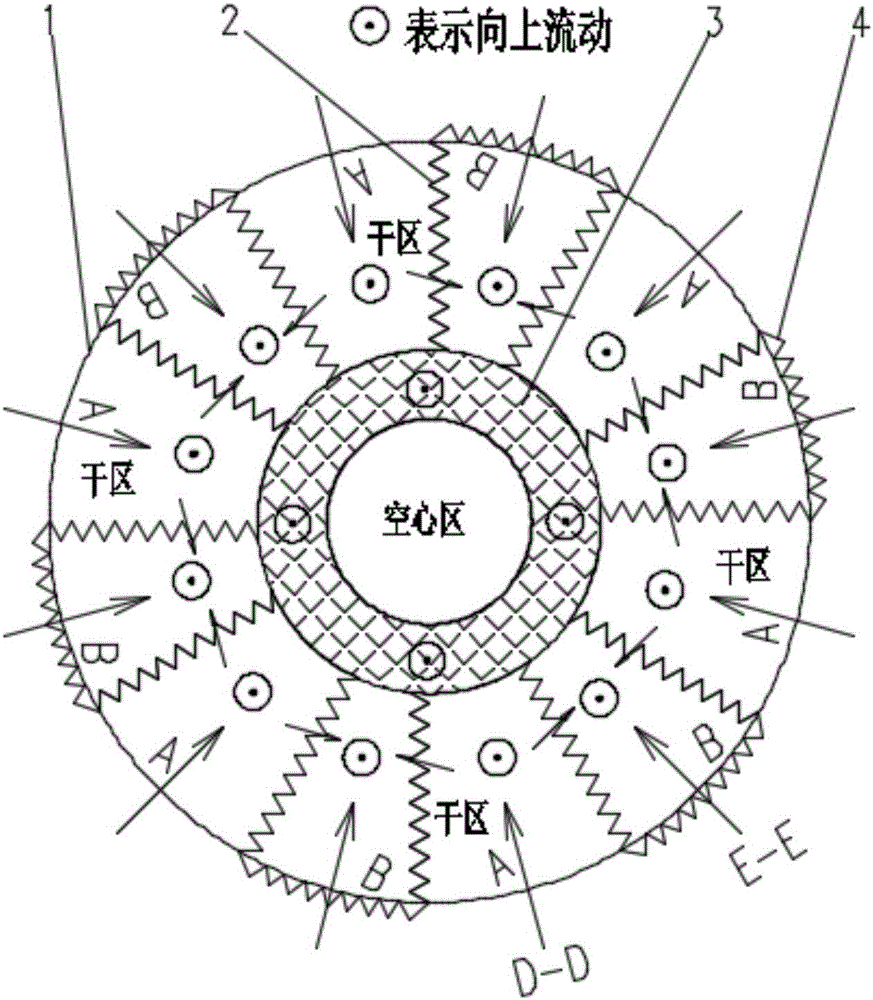

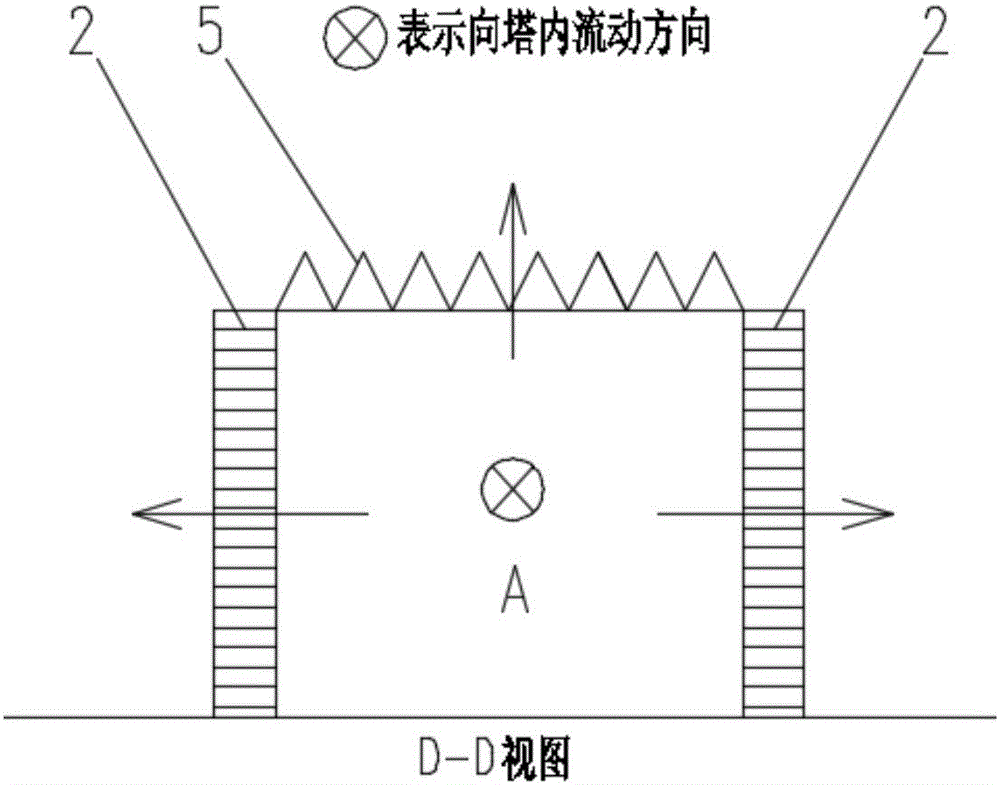

[0032] Example 1: A large-scale dry-wet mixing cooling tower with annular packing. The cooling tower includes a dry zone and a wet zone.

[0033] Such as figure 1 As described, a plurality of cooling units are arranged in the dry zone, and the cooling units are respectively arranged at different positions of the dry zone according to the horizontal direction and the vertical direction. Specifically, the vertically arranged cooling unit is the vertical cooling unit 2 in the dry zone tower, the horizontally arranged cooling unit is the horizontal cooling unit 5 in the dry zone tower, and the cooling unit arranged at the bottom circumference of the cooling tower barrel 1 is the dry zone. Zone air inlet cooling unit 4.

[0034] The wet zone includes water distribution zone 9, filling zone 3, hollow zone 7, rain zone 10 and wet collection tank 8.

[0035] The air inlet height of the dry zone H( figure 1 Shown) Refer to the design regulations of the air cooling tower, and the specific hei...

Embodiment 2

[0055] Embodiment 2: A cooling system for a thermal power plant. A cooling tower is installed in the cooling system of the thermal power plant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com