Thin polyolefin shrink film and production process thereof

A polyolefin and shrink film technology, applied in the field of polyolefin heat shrinkable film, can solve the problems of easy pleating and cutting, difficulty, low heat sealing performance, etc., and achieve the goal of improving heat sealing performance, increasing hardness and good heat sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

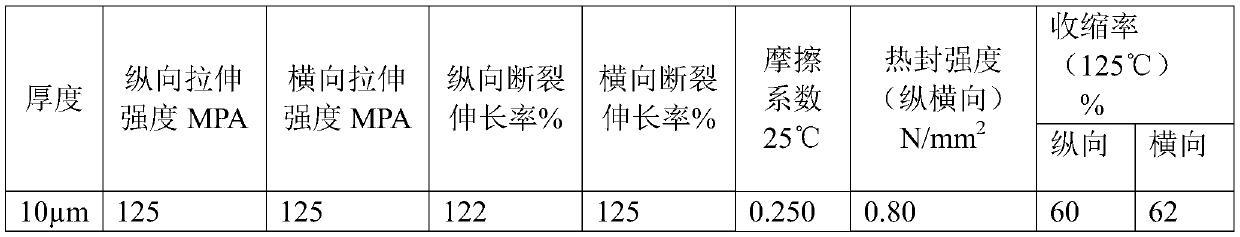

Embodiment 1

[0018] The raw materials and weight ratio of the inner and outer surface layers are: ternary random copolymer polypropylene (FS6612 of Singapore TPC Company) 96.5%, anti-sticking agent (ABPOF-4 anti-sticking masterbatch of Jiangsu Jingliang Polymer Materials Co., Ltd.) 2.5%, smooth (Smoothing masterbatch of SPOF07 from Jiangsu Jingliang Polymer Material Co., Ltd.) 1%;

[0019] The raw materials and weight ratio of the intermediate layer are: octa-carbon linear low-density polyethylene (2045G of Dow, USA) 44%, octa-carbon linear low-density polyethylene (2049G of Dow, USA) 40%, metallocene LLDPE (such as Eke Sen's 1018FA) 15% and slip agent (the slip masterbatch of Jiangsu Jingliang Polymer Materials Co., Ltd. SPOF07) 1%.

[0020] Production Process:

[0021] 1) Mixing: Put the selected raw materials into the kneader according to the proportion and mix them evenly. The mixing time is 15 minutes and the rotation speed is 360r / min;

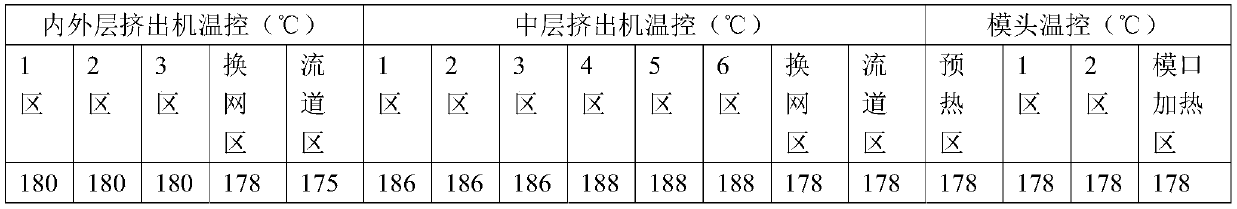

[0022] 2) Plasticizing extrusion: add the uniformly m...

Embodiment 2

[0037] The raw material and weight ratio of the inner and outer surface layers are: ternary random copolymer polypropylene (FS6612 of Singapore TPC Company) 96%, anti-sticking agent (ABPOF-4 anti-sticking masterbatch of Jiangsu Jingliang Polymer Material Co., Ltd.) 3%, smooth (Smoothing masterbatch of SPOF07 from Jiangsu Jingliang Polymer Material Co., Ltd.) 1%;

[0038] The raw materials and weight ratio of the intermediate layer are: eight-carbon linear low-density polyethylene (2045G of Dow, U.S.) 45%, eight-carbon linear low-density polyethylene (2049G of Dow, U.S.) 40%, metallocene LLDPE (such as Eck Sen's 1018FA) 14% and slip agent (the slip masterbatch of Jiangsu Jingliang Polymer Materials Co., Ltd. SPOF07) 1%.

[0039] The production process is the same as in Example 1.

Embodiment 3

[0041] The raw materials and weight ratio of the inner and outer surface layers are: ternary random copolymer polypropylene (FS6612 of Singapore TPC Company) 97%, anti-sticking agent (ABPOF-4 anti-sticking masterbatch of Jiangsu Jingliang Polymer Materials Co., Ltd.) 2%, smooth (Smoothing masterbatch of SPOF07 from Jiangsu Jingliang Polymer Material Co., Ltd.) 1%;

[0042] The raw materials and weight ratio of the intermediate layer are: octa-carbon linear low-density polyethylene (2045G of Dow, USA) 44%, octa-carbon linear low-density polyethylene (2049G of Dow, USA) 41%, metallocene LLDPE (such as Eck Sen's 1018FA) 14% and slip agent (the slip masterbatch of Jiangsu Jingliang Polymer Materials Co., Ltd. SPOF07) 1%.

[0043] The production process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com