Wax mold manufacturing cold water device

A cooling water device and wax mold technology, which is applied in household refrigeration equipment, lighting and heating equipment, casting and molding equipment, etc., can solve the problems of poor cooling effect, high temperature of cold water, single cooling method of wax mold cold water tank, etc. Achieve better cooling effect and lower water temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

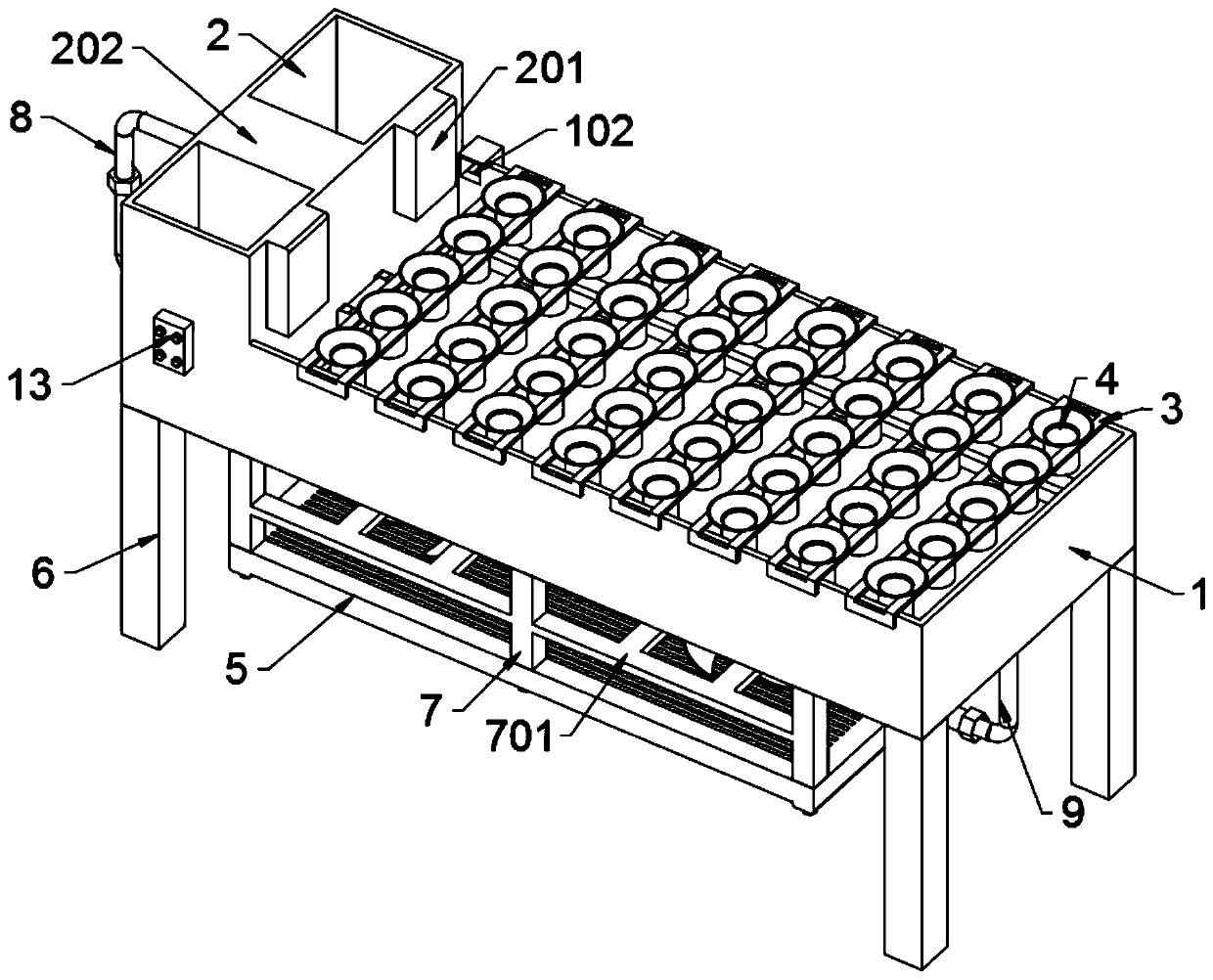

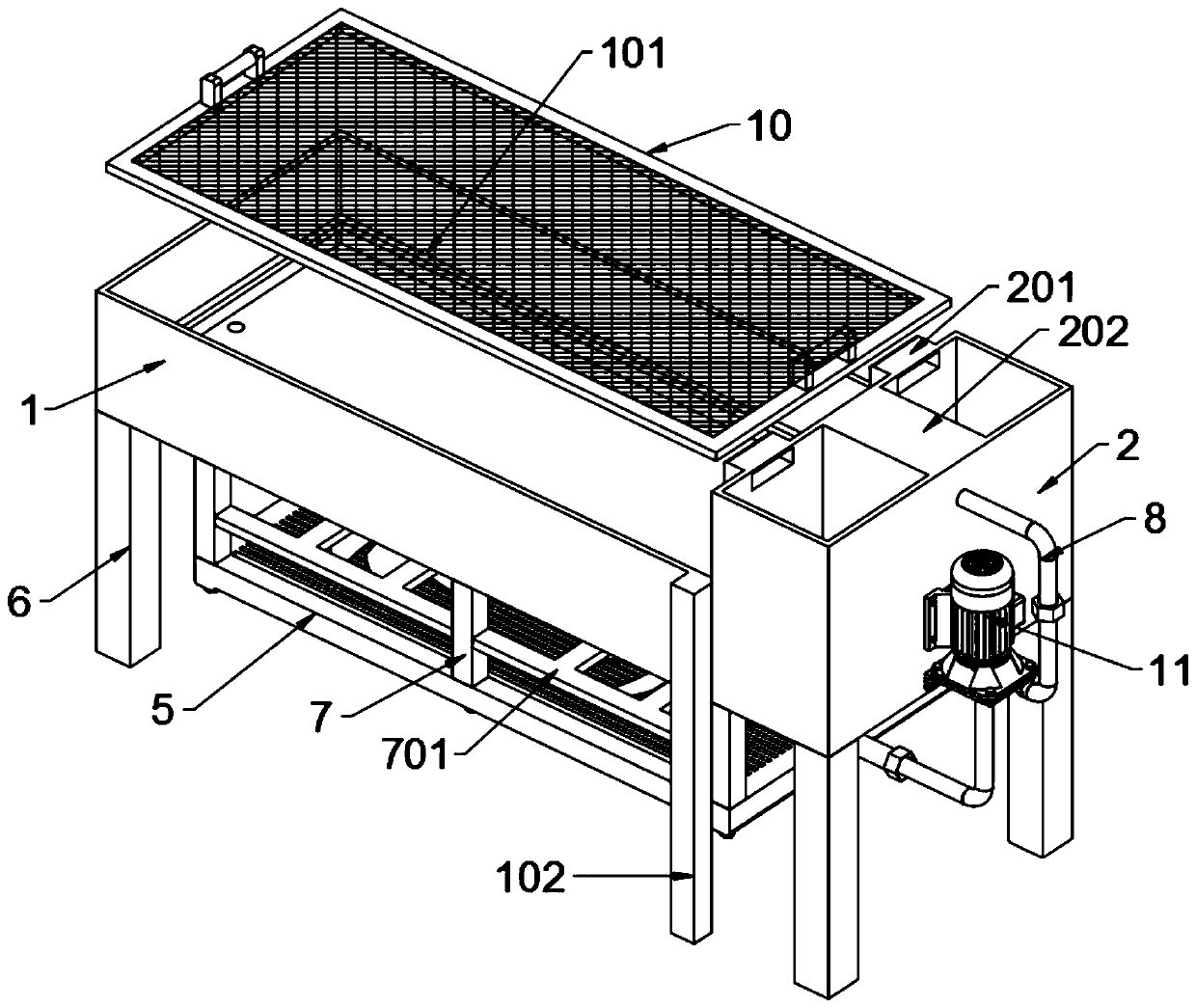

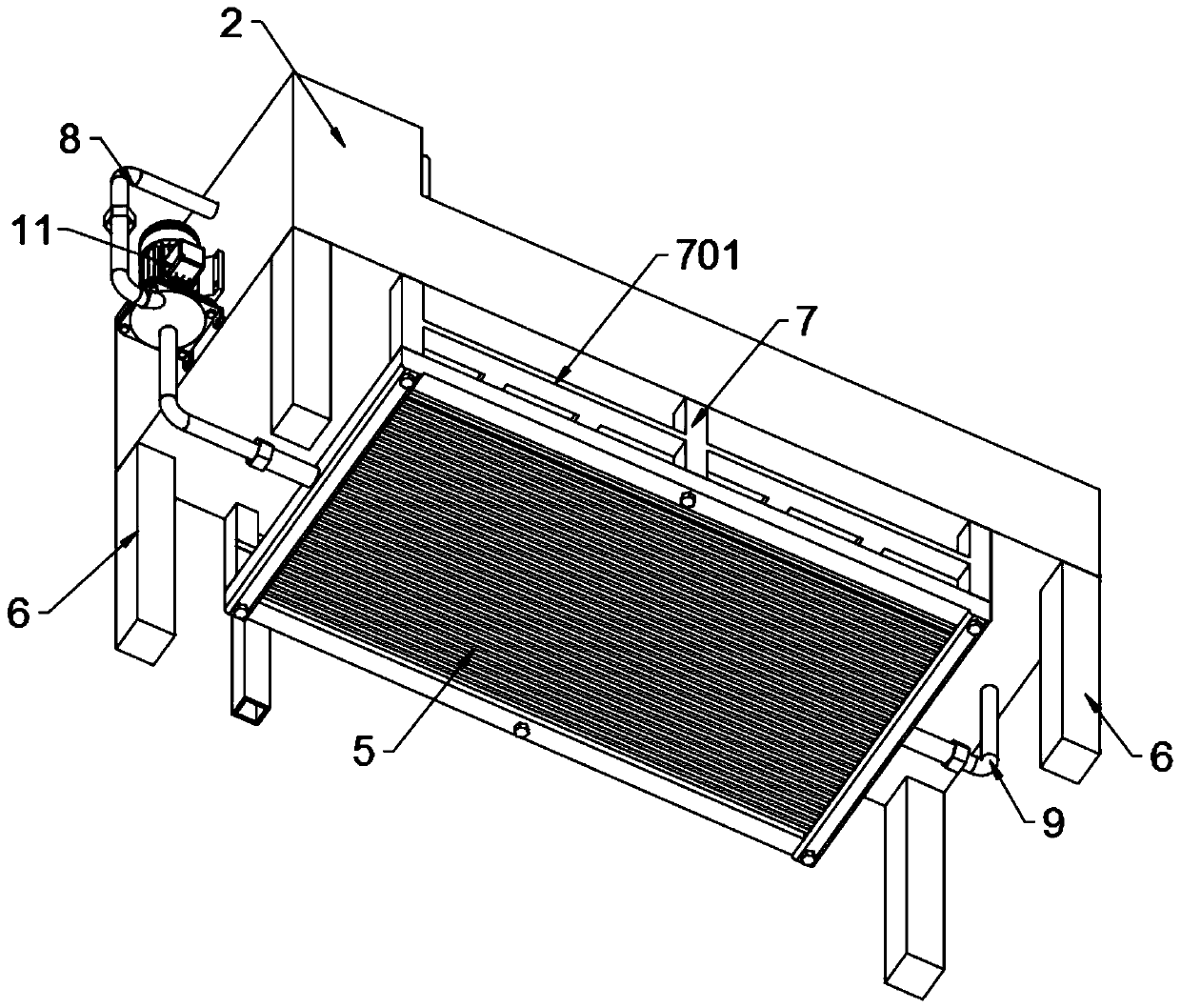

[0040] as attached figure 1 To attach Figure 9 Shown:

[0041]The invention provides a cooling water device for making wax molds, which includes a cold water tank body 1, a rectangular frame 101, an overflow pipe 102, an ice box 2, an overflow pipe 201, a water inlet tank 202, a water leakage plate 203, a mold frame 3, and a wax film Tube 4, radiator 5, support leg 6, boom 7, mounting frame 701, water inlet pipe 8, water outlet cage 801, water suction pipe 9, filter screen 10, water pump 11, fan 12 and control panel box 13, the cold water tank The main body 1 is arranged in a rectangular shape as a whole, and an ice cube box 2 is welded on its left end, and four support legs 6 are symmetrically supported on the left and right ends of the bottom of the cold water tank main body 1; the tail section of the water suction pipe 9 is bent to the left It is installed, and its through-welding is suspended on the right side of the bottom plate of the cold water tank body 1; multiple ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com