Nano-diamond automatic repair liquid for reciprocating piston engine

A piston engine, nano-diamond technology, applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of nano-diamond agglomeration, high cost, complex formula, etc., and achieve enlarged contact area, low cost, and good dispersion effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

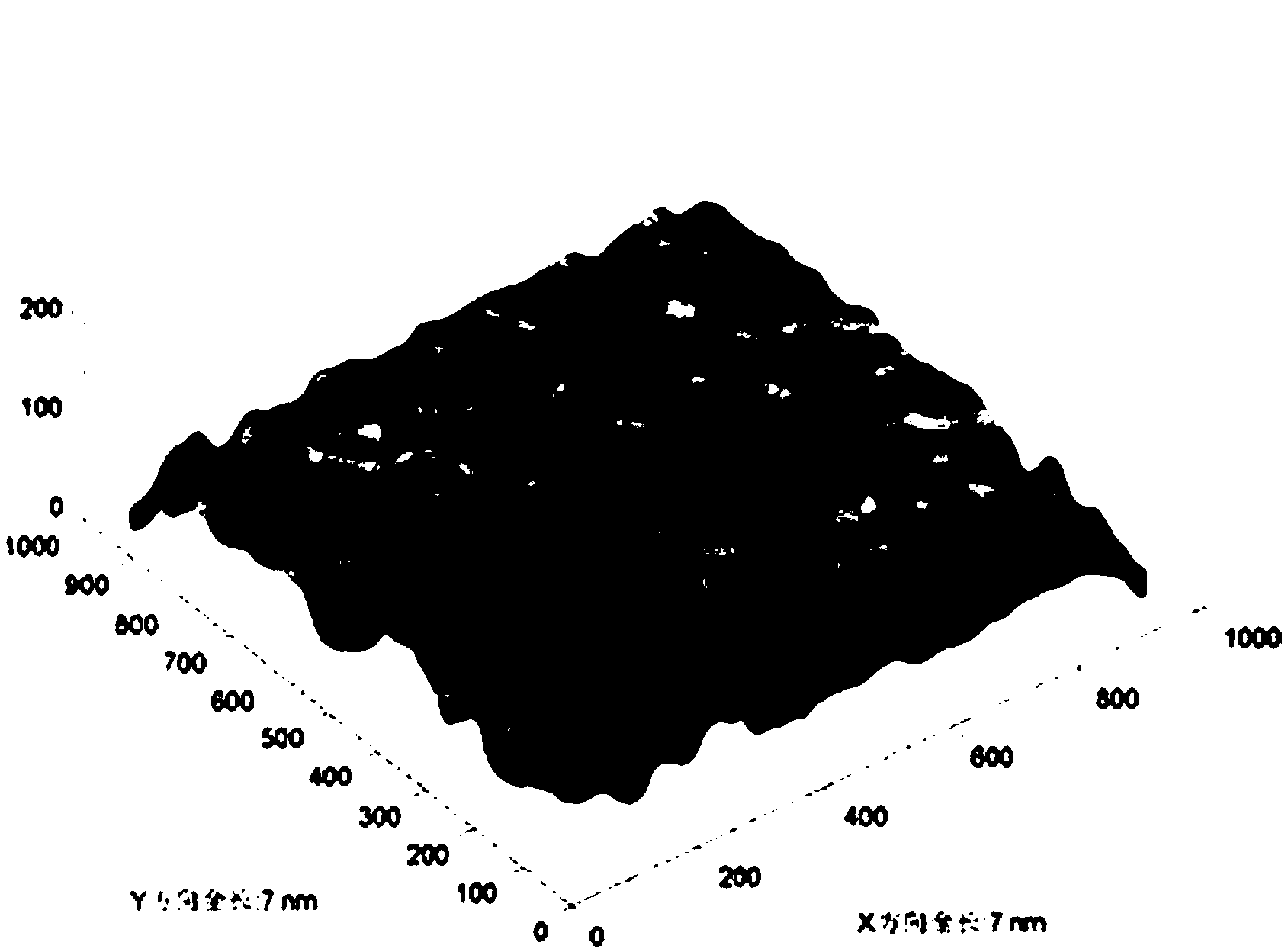

Image

Examples

Embodiment 1

[0018] (1) Add 1mg of nano-diamond to 1L OP-10 dispersant, stir for more than 20min, and then let it stand still. After the bubbles completely disappear, a black precipitate appears at the bottom, and pour out the supernatant; the nano-diamond is prepared by the explosion method. The purified nano-diamond ash powder (Lanhua Institute of Chinese Academy of Sciences) has a purity greater than 90%, and is a spherical particle with a particle diameter of 2-4nm and uniform particle diameter.

[0019] (2) Add the above supernatant to the lubricating oil according to the mass percentage of the supernatant and the lubricating oil being 20%:80%, and stir and mix to obtain the self-repairing liquid. Before using the automatic repair liquid of the present invention, according to the mass ratio of the automatic repair liquid and lubricating oil, dilute again according to the ratio of 10-30%: 90%-70%, and then add 100ml of the above-mentioned diluent according to every 1L of motorcycle engi...

Embodiment 2

[0021] (1) Add 0.8mg of nano-diamonds to 1L OP-10 of the dispersant, stir for more than 20 minutes, and then let it stand still. After the bubbles completely disappear, a black precipitate appears at the bottom, and pour out the supernatant; the nano-diamonds are prepared by the explosion method The purified nano-diamond ash powder (Lanhua Institute of Chinese Academy of Sciences) has a purity greater than 90%, and is spherical particles with a particle diameter of 2-4nm and uniform particle diameter.

[0022] (2) Add the above supernatant to the lubricating oil according to the mass percentage of supernatant and lubricating oil: 30%:70%, stir and mix to obtain the automatic repairing liquid. Before using the automatic repair liquid of the present invention, according to the mass ratio of the automatic repair liquid and lubricating oil, dilute again according to the ratio of 10-30%: 90%-70%, and then add 100ml of the above-mentioned diluent according to every 1L of motorcycle e...

Embodiment 3

[0024] (1) Add 1.2 mg of nano-diamonds to 1L OP-10 of the dispersant, stir for more than 20 minutes, and then let it stand still. After the bubbles completely disappear, a black precipitate appears at the bottom, and the supernatant is poured out; the nano-diamonds are prepared by the explosion method The purified nano-diamond ash powder (Lanhua Institute of Chinese Academy of Sciences) has a purity greater than 90%, and is spherical particles with a particle diameter of 2-4nm and uniform particle diameter.

[0025] (2) Add the above-mentioned supernatant to the lubricating oil according to the mass percentage of the supernatant and the lubricating oil being 10%:90%, and stir and mix to obtain the self-repairing liquid. Before using the automatic repair liquid of the present invention, according to the mass ratio of the automatic repair liquid and lubricating oil, dilute again according to the ratio of 10-30%: 90%-70%, and then add 100ml of the above-mentioned diluent according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com