Detection tool and method for measuring distance dimension of center plane of arc structure

A technology of center plane and size is applied in the field of inspection tools for measuring the distance and size of the center plane of the arc structure, which can solve the problems such as the inability to guarantee the size accuracy, the inability to obtain accurate distance and size values, and the large error of measurement values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

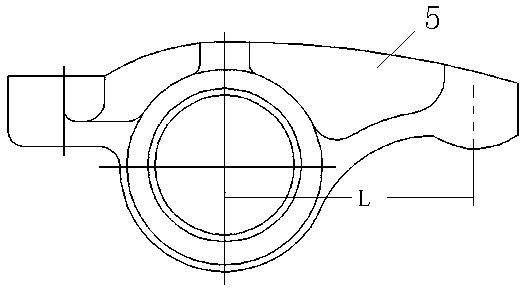

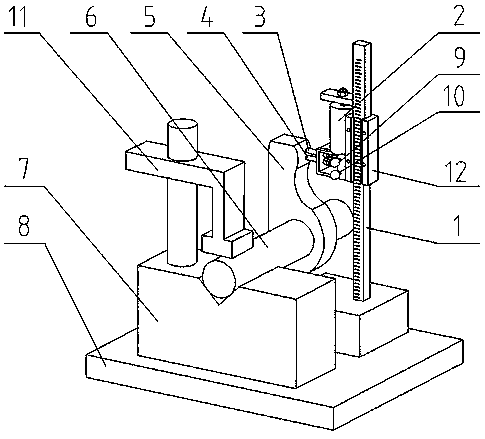

[0034]The inspection tool for measuring the distance from the center plane of the circular arc structure includes a square box 7 placed on the detection platform 8, a positioning shaft 6 fixed on the square box 7, and a measured rocker mounted on the positioning shaft 6. Arm 5; also includes a height vernier caliper, power supply battery 2, and the detection assembly that is installed on the said height vernier caliper auxiliary scale 12; Said detection assembly includes the first detection head 3 and the second detection head 4 that are arranged in parallel up and down, And the first indicator light 9 and the second indicator light 10 respectively corresponding to the first detection head 3 and the second detection head 4; The negative pole of 2 is connected to the first indicator light 9 and the second indicator light 10 through a wire, and the first indicator light 9 and the second indicator light 10 are respectively connected to the first detection head 3 and the second det...

Embodiment 2

[0043] The method of measuring the distance dimension from the center plane of the arc structure is based on the measuring and checking tool of the distance dimension from the center plane of the arc structure to realize the following operation steps:

[0044] S1: On the detection platform 8, first put the center hole of the rocker arm 5 under test on the positioning shaft 6, and position the positioning shaft 6 tightly through the square box 7 and the clamp 11 on its upper part;

[0045] S2: Use a common height vernier caliper to find the level of the tested rocker arm 5, and then rotate the square box 7 by 90 degrees. At this time, the center plane of the arc structure is parallel to the detection platform 8;

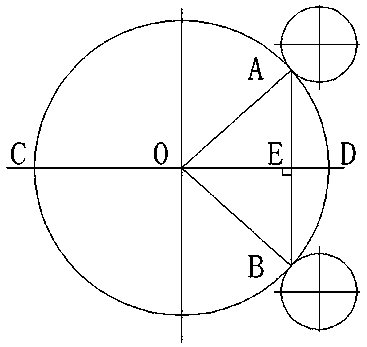

[0046] S3: Adjust the first detection head 3 and the second detection head 4 on the height vernier caliper, so that the center line of the two steel balls a on the first detection head 3 and the second detection head 4 is perpendicular to the detection platform 8; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com